Great Planes RimFire 250 Power System User Manual

Page 2

10

IMPORTANT PRECAUTIONS

• Once the battery is connected to the ESC, stay clear of the motor

and prop.

• DO NOT apply an input voltage that exceeds the maximum

specifi cation of each motor.

• DO NOT apply currents to the motor that exceed the maximum

specifi cations of each motor.

• DO NOT allow the input connectors to accidentally touch each other

while power is applied to the motor. Make sure all input connections

are insulated electrically.

• DO NOT allow water or moisture to enter the motor, as it can

cause permanent damage to the motor and possibly short out the

attached ESC.

• DO NOT cut the coated wires from the motor. If you must remove the

bullet connectors, unsolder them.

• Allow the motor to cool after each fl ight.

• The motor shaft of the motor will rotate at very high rpm. DO

NOT attempt to touch the shaft while it is rotating. If setting up

the motor/ESC on the workbench, make sure the motor is securely

attached and that nothing is attached to the motor shaft BEFORE

applying power.

• NEVER attempt to use a damaged motor (having mechanical or

electrical defects).

• ElectriFly carries a complete line of Ammo (in-runner style) and

RimFire (out-runner style) brushless motors, gear drives, motor

mounts, prop adapters and speed controls. For a complete list of

these products, check out our web site at:

www.greatplanes.com www.electrifl y.com

or visit your nearest hobby shop that carries the full line of Great

Planes and ElectriFly products.

Copyright © 2009

GPMG4502

The motor can now be mounted from the back side of a fi rewall with only

the shaft protruding forward of the fi rewall. The prop saver adapter or an

optional collet or set screw type adapter can be used to attach the propeller

to the motor.

Collet Type Prop Adapter Installation

Slide the 3mm prop shaft

over the motor shaft. Next

slide the prop shaft retainer

over the prop shaft. Note that

the hole through the retainer

is tapered. Make sure that the

side with the larger diameter

hole is installed fi rst. Install

the prop, prop washer and

then the prop nut. Tighten the

prop nut against the prop. This will cause the tapered hole in the prop shaft

retainer to squeeze the prop shaft around the output shaft. Carefully pull on

the prop to make sure it is securely attached to the motor shaft.

Set Screw Type Prop Adapter Installation

Slide the 3mm prop adapter

over the motor shaft. Tighten

both of the set screws against

the shaft. Install the prop,

prop washer and then the

prop nut. Tighten the prop nut

against the prop. Carefully

pull on the prop to make sure

it is securely attached to the

motor shaft.

8

INSTALL THE BRUSHLESS ESC

Mount your ESC in the desired location. Always make sure that the ESC is

positioned so that it gets some cooling air fl owing over it.

Use the instructions included with the ESC to correctly connect the ESC.

9

RIMFIRE MOTOR MAINTENANCE

RimFire brushless motors require virtually no maintenance. There are no

brushes to wear out and replace. The precision bearings have a very long

service life and should last a very long time. The internal parts of the motor

should not require any cleaning. The only thing that needs to be checked is

to make sure all the screws and set screws remain tight.

Optional Reverse Shaft Installation

An optional reversing shaft is available for purchase separately

(GPMG1403) and will allow you to mount the RimFire 250 motor

behind the fi rewall.

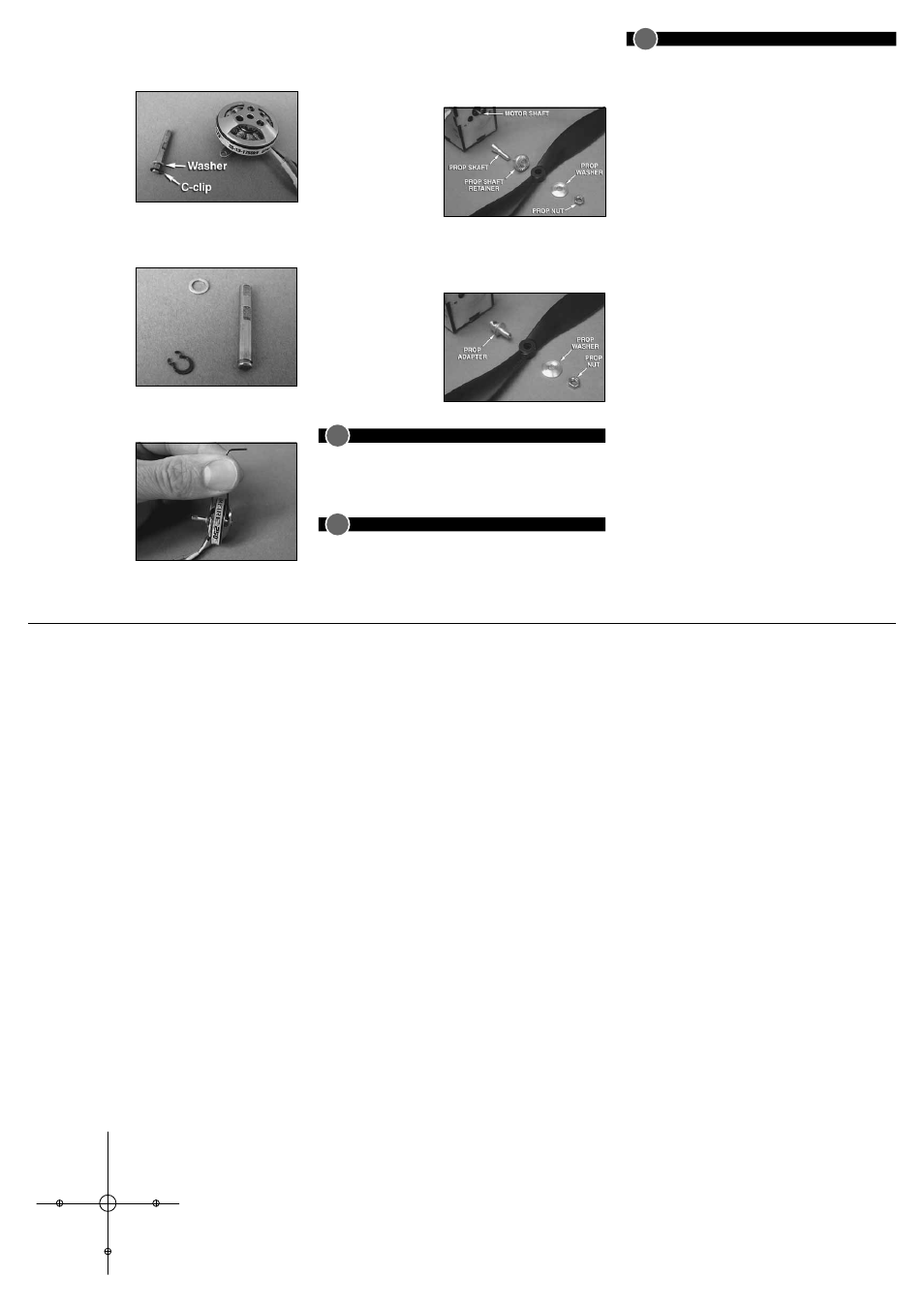

Remove the set screw

that secures the motor

shaft to the motor front

case (this requires a

0.9mm allen key which

is not included). With

the set screw removed,

push the motor shaft out

through the bottom of

the motor being careful

not to lose the washer on the shaft. Tip: The shaft is a very tight fi t in

the motor case. An arbor press machine or a drill press (with a small

drill bit inserted upside down in the press) can be used to easily press

the shaft out of the motor.

Carefully remove the

c-clip from the aft end of

the motor shaft. A fi ne,

fl athead screwdriver or

small needle nose pliers

are useful in doing this.

Tip: Crawling around on

your hands and knees

looking for a lost c-clip is

no fun. Wrap a sandwich

bag around the shaft

before attempting to remove the c-clip. If the c-clip fl ies off the shaft,

it will be contained by the bag. Also, be sure to wear safety glasses

when removing the clip!

Reinstall the c-clip into

the groove on the reverse

shaft along with the

washer. Insert the reverse

shaft into the motor case.

The fl at spot on the shaft

near the c-clip groove

must be aligned with the

set screw in the motor

front case. Tighten the

set screw against the fl at

spot on the shaft.

Template

RimFire 250 Accessory and Spare Parts

GPMQ4625

Rimfi re Prop Saver (complete set)

GPMM3111 2mm gold plated bullet connectors - female (3)

GPMM3110 2mm gold plated bullet connectors - male (3

GPMG1401

Rimfi re 250 Replacement Shaft Kit

GPMG1403

Rimfi re 250 Reverse Run Shaft

GPMG1451

Rimfi re 250 Bearings (2)

GPMG1430

C-clip (10) for 3mm Rimfi re Motor Shafts

GPMG1405

Prop Saver O-rings (5)