FloAire Direct Expansion Coil Modules User Manual

Page 8

8

VI. If there are multiple joints to be made, move the torch and begin heating the next

joint. This will save time and fuel.

VII. Let the joints cool naturally. Cooling the joints with water could cause the joints

to fail prematurely.

2. Pressure testing the lines.

A. Charge the lines with Dry Nitrogen to design operating PSI.

B. If

the

pressure

changes

drastically, you have a leak. If

the pressure drops slowly, you

may have a leak. If the

pressure holds for 15 minutes,

proceed to the next step.

I. Ultrasonically

leak

check all joints.

II. After all joints have

been tested, bleed off

the excess pressure,

and repair the joints.

You will have trouble

repairing the joints if

there is pressure in the

lines.

III. Start

the

pressure

testing over.

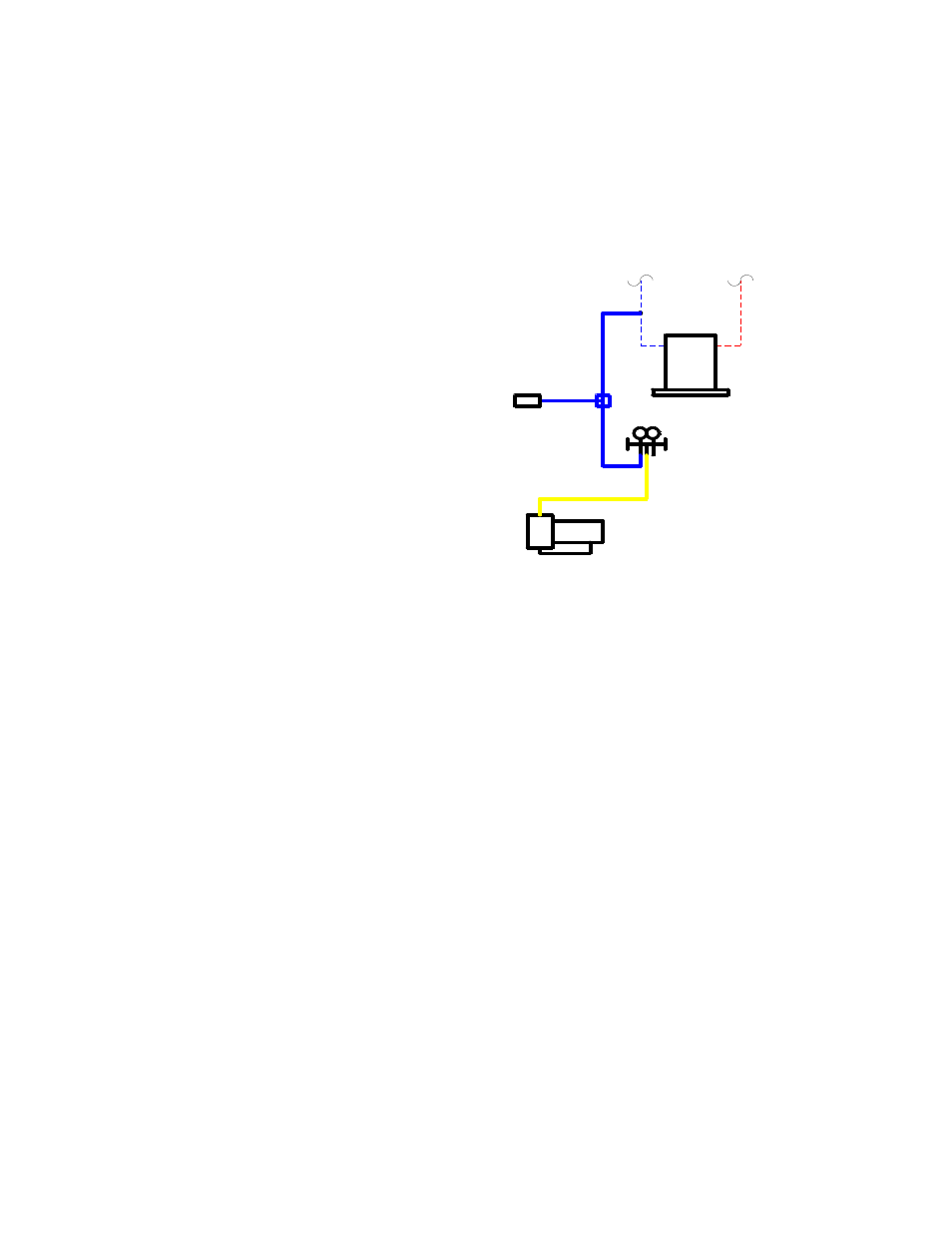

C O M P RES SO R

G AUG E

SUC TIO N LINE

M IC R O M ETER

V AC UUM PU M P

LEA K TEST AND PREP

FO R REFRIGERA NT C HA RG E

T o V acuum Pum p (Yellow)