FloAire Direct Expansion Coil Modules User Manual

Page 7

7

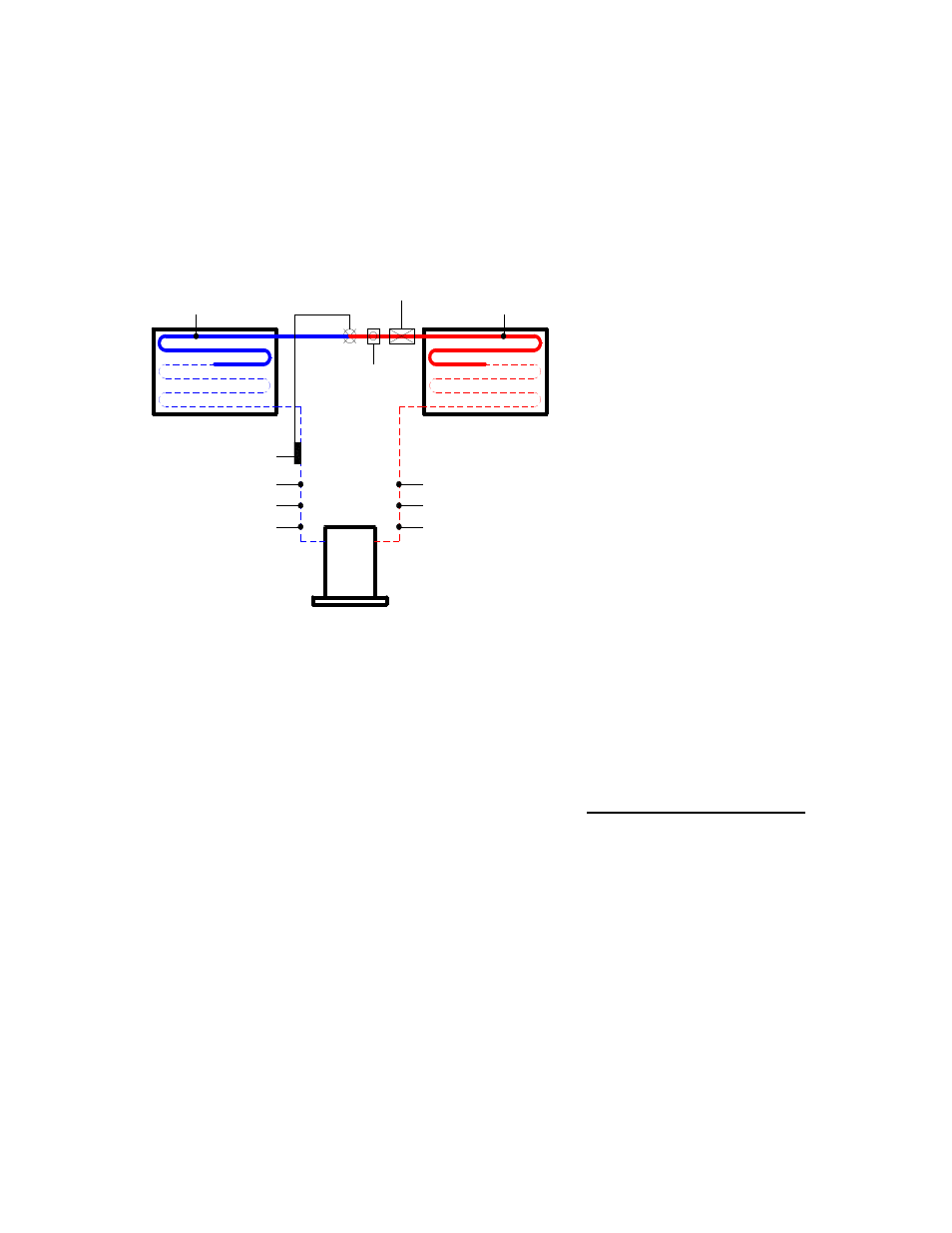

COMPRESSOR

EVAPORATOR

CONDENSER

THERMAL

EXPANSION

VALVE

HIGH-PRESSURE VAPOR

HIGH-PRESSURE LIQUID

LOW PRESSURE VAPOR

LOW PRESSURE LIQUID

VALVE SENSING BULB

EXPANSION

THERMAL

SUCTION PORT

HOT GAS PORT

DRIER FILTER

SIGHT GLASS

LOW TEMP / PSI SWITCH

HIGH TEMP / PSI SWITCH

BASIC REFRIGERANT PIPING

Depending on the distance between the condenser and the module, there may be other components

installed in the lines. Here is a short list of components found in the lines. A filter dryer, which removes

any moisture from the refrigerant, needs to be installed close to the compressor section. A sight glass

should be installed close to the thermal expansion valve. This will help in diagnosing any problems with

the air conditioning (A/C) setup. A solenoid is required when the liquid line exceeds 75 Ft. This will

prevent the build up liquid refrigerant from entering the compressor while the unit is off. If the suction line

exceeds 75 Ft, an accumulator will need to be installed to prevent any liquid refrigerant from entering into

the compressor.

1. Plumb Liquid and

Suction Lines.

A. Run

the

lines. Keep

the lines as

short and as

straight

as

possible.

Also,

keep

the

lines

away

from

any

sharp

edge. The

lines

may

vibrate some

during

normal

use

and this will

keep

the

lines

from

breaching.

I. There are two different types of thermal expansion valves. Internally equalized

valves will have 2 connections, one for liquid to the valve and one to the

distributor of the coil. The externally equalized will have an additional fitting for

the capped line from the coil.

II. If the coil has a hot gas bypass, install this now with the instructions included in

the kit.

B. Braze the joints. These joints will be under great pressure, so proper joint construction is

imperative. All joints need to be made using Silver-Phosphorus or Copper-Phosphorus

brazing filler, available from a local welding store. DO NOT USE SOFT SOLDER, this

material does not produce a strong enough joint. It is also recommended to flow dry

nitrogen through the lines to prevent joint oxidation while brazing.

I. Clean both mating surfaces with Emory cloth.

II. Fit both pieces together. If there are multiple joints within a short distance, clean

and fit them together as well.

III. There are some parts in the lines that cannot be overheated. Parts like the

thermal expansion valves, solenoid valves, sight glasses, and accumulators

cannot exceed 200

°

F. Place a wet rag around these parts to cool them while

you braze the joints, and avoid pointing the torch flame directly on these devices.

IV. Heat using a TurboTorch® or equivalent torch using MAPP gas or Acetylene.

Move the torch back and forth on the pipes. This will distribute the heat more

evenly around the part. When the parts glow a dull red, pull the torch away

slightly. Be careful not to over heat the pipe. Smaller pipes, if overheated, will

begin to melt and burn.

V. Add brazing wire until the entire joint is covered. On larger diameters of pipe,

you may need to move your torch around the diameter of the pipe.