Low pressure switch, Service valves, Accurater ா (bypass type) device – Carrier LIGHT COMMERCIAL CONDENSING UNITS 38HDL018-060 User Manual

Page 8: Refrigerant charging

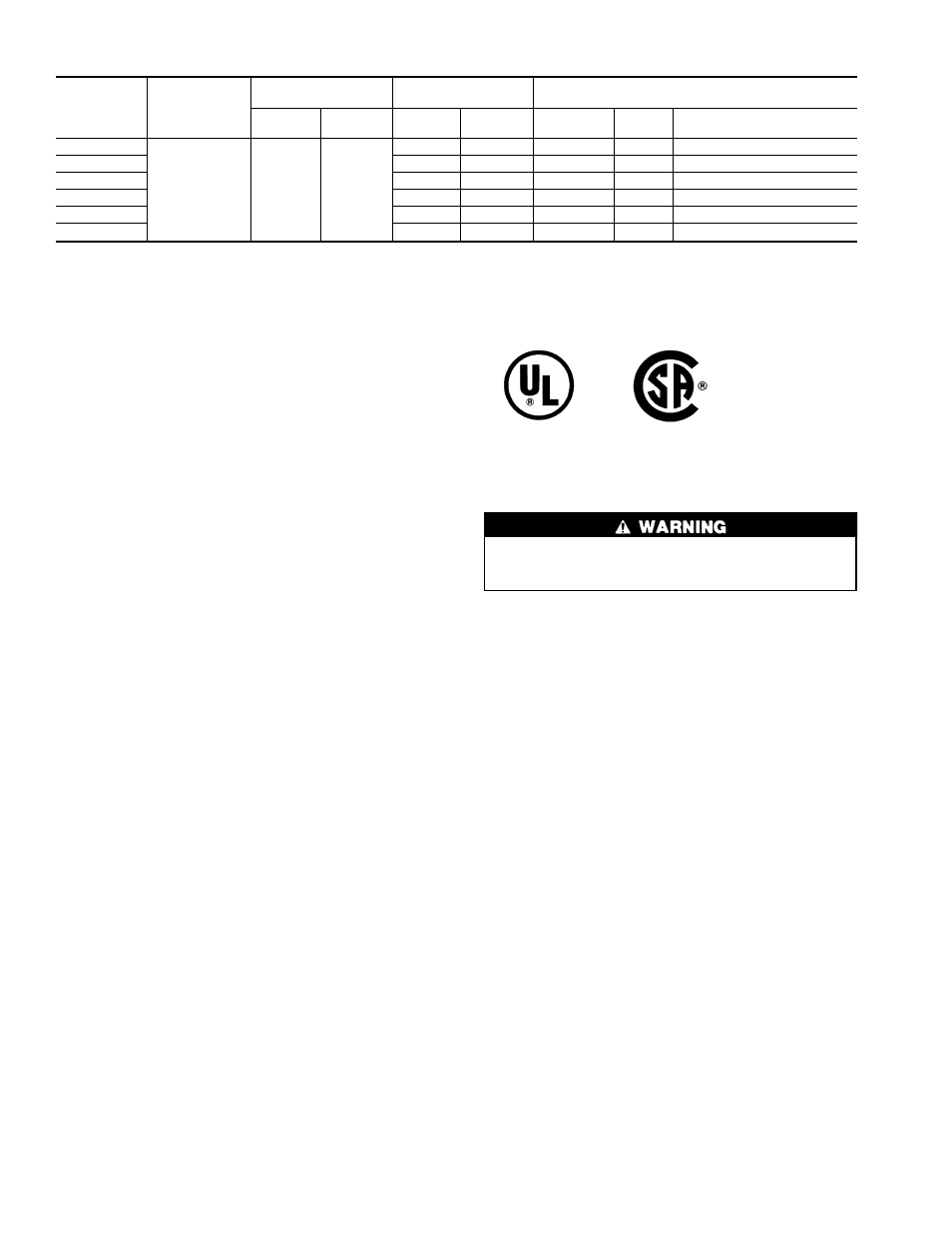

Table 3 — Electrical Data

UNIT SIZE

38HDL

V-PH-Hz

OPERATIONAL

VOLTAGE*

COMPRESSOR

POWER SUPPLY

Min

Max

RLA

LRA

Fan FLA

MCA

Max Fuse† or HACR-Type

Ckt Bkr Amps

018

208/230-1-60

187

254

10.7

47.0

.70

14.1

25

024

13.2

59.0

.70

17.2

30

030

15.7

73.0

.70

20.3

35

036

14.2

86.7

.70

18.5

30

048

24.3

131.0

1.45

31.8

50

060

28.6

170.0

1.45

37.2

65

LEGEND

FLA

— Full Load Amps

HACR — Heating, Air Conditioning, Refrigeration

LRA

— Locked Rotor Amps

MCA

— Minimum Circuit Amps per NEC Section 430-24

NEC

— National Electrical Code (U.S.A. Standard)

RLA

— Rated Load Amps (Compressor)

*Permissible limits of the voltage range at which unit will operate

satisfactorily.

†Time-delay fuse.

NOTES:

1. Control circuit is 24 v on all units and requires an external power

source.

2. All motors and compressors contain internal overload protection.

3. In compliance with NEC (U.S.A. Standard) requirements for mul-

timotor and combination load equipment (refer to NEC Articles 430

and 440), the overcurrent protective device for the unit shall be

fuse or HACR breaker.

4. Motor RLA values are established in accordance with UL (Under-

writers’ Laboratories) Standard 465 (U.S.A. Standard).

Low Pressure Switch

— This switch, mounted on the

suction line, has fixed non-adjustable settings. To check pres-

sure switch, attach pressure gage to suction service valve gage

port. Slowly close liquid shutoff valve and allow compres-

sor to pump down. Do not allow compressor to pump down

below 2 psig (14 kPa). Compressor should shut down when

suction pressure drops to cutout pressure in Tables 1A and

1B, and should restart when pressure builds up to cut-in pres-

sure shown after accessory CLO (compressor lockout) switch

has been reset and accessory Time Guard

II device has com-

pleted its timing cycle.

Service Valves

— The service valves in the outdoor unit

come from the factory frontseated. This means the refrig-

erant charge is isolated from the line-set connection ports.

To prevent damage to the valve, use a wet cloth or other

acceptable heat sink material on the valve before brazing.

The service valves must be backseated (turned counter-

clockwise until seated) before the service port caps can be

removed and the hoses of the gage manifold connected. In

this position, refrigerant has access from the through out-

door and indoor unit. The service valve cannot be field re-

paired; only a complete valve or valve stem seal and service

port caps are available for replacement.

AccuRater

ா

(Bypass Type) Device

— See Fig. 4

for bypass type AccuRater device components. The piston

has a refrigerant metering hole through it. The retainer forms

a stop for the piston in the refrigerant bypass mode and a

sealing surface for liquid line flare connection. To check, clean

or replace piston:

1. Shut off power to unit.

2. Pump down using Pumpdown Procedure section on

page 7.

3. Remove liquid line flare connection from AccuRater

device.

4. Pull retainer out of body, being careful not to scratch flare

sealing surface. If retainer does not pull out easily, care-

fully use locking pliers to remove retainer.

5. Slide piston out by inserting a small soft wire, with small

kinks, through metering hole. Ensure metering hole, seal-

ing surface around piston cones, and fluted portion of pis-

ton are not damaged.

6. Clean piston refrigerant metering hole.

7. Replace retainer O-ring before reassembling AccuRater

device (O-ring part no. 99CC501052).

Refrigerant Charging

To prevent personal injury, wear safety glasses and gloves

when handling refrigerant. Do not overcharge system

— this can cause compressor flooding.

NOTE: Do not vent or depressurize unit refrigerant to atmos-

phere. Remove and reclaim refrigerant following practice.

SUPERHEAT METHOD (COOLING, NON-TXV) — To

check and adjust charge during cooling season, use Tables

4A-5B and the following procedure:

1. Operate unit a minimum of 15 minutes before checking

charge.

2. Measure suction pressure by attaching a gage to suction

valve service port.

3. Measure suction line temperature by attaching a service

thermometer to unit suction line near suction valve. In-

sulate thermometer for accurate readings.

4. Measure outdoor coil inlet-air dry bulb temperature with

a second thermometer.

5. Measure indoor coil inlet-air wet bulb temperature with

a sling psychrometer.

6. Refer to Tables 4A and 4B. Find air temperature enter-

ing outdoor coil and wet-bulb temperature entering

indoor coil. At this intersection, note the superheat

temperature.

7. Refer to Tables 5A and 5B. Find superheat temperature

and suction pressure and note suction line temperature.

8. If unit has higher suction line temperature than charted

temperature, add refrigerant until charted temperature,

add refrigerant until charted temperature is reached.

9. If unit has lower suction line temperature than charted

temperature, remove and recover refrigerant until charted

temperature is reached.

10. If air temperature entering outdoor coil or pressure at

suction valve changes, charge to new suction line tem-

perature indicated on chart.

NOTE: The above procedure is independent of indoor air

quantity.

8