Maintenance, Lubrication, Cleaning coils – Carrier LIGHT COMMERCIAL CONDENSING UNITS 38HDL018-060 User Manual

Page 10: Table 7 — recommended compressor oils

MAINTENANCE

Before performing recommended maintenance, be sure

unit main power is off. Failure to do so may result in

electrical shock or injury from rotating fan blades.

Lubrication

FAN-MOTOR BEARINGS — Oiling holes are provided at

each end of the condenser-fan motor. Remove fan motor and

lubricate motor with 32 drops (16 drops per hole) of SAE-10

(Society of Automotive Engineers) non-detergent oil at in-

tervals described below:

• Annually, when environment is very dirty, ambient tem-

perature is higher than 105 F (40 C), and average unit op-

erating time exceeds 15 hours a day, or

• Every three years, when environment is reasonably clean,

ambient temperature is less than 105 F (40 C), and unit

operating time averages 8 to 15 hours per day, or

• Every 5 years when environment is clean, ambient tem-

perature is less than 105 F (40 C), and unit operating time

averages less than 8 hours per day.

COMPRESSOR — Compressor contains factory oil charges;

replace oil when lost. See Tables 1A and 1B for oil recharge

and refer to Carrier Standard Service Techniques Manual,

Chapter 1, pages 1 to 21 for oil recharging procedure. See

Table 7 for recommended compressor oils.

Cleaning Coils

— Coil should be washed out with wa-

ter or blown out with compressed air. Note that the blow-

thru design causes dirt and debris to build up on the inside

of the coils.

Clean coil annually or as required by location and outdoor

air conditions. Inspect coil monthly and clean as required.

Fins are NOT continuous through coil sections. Dirt and de-

bris may pass through the first section, become trapped be-

tween the rows of fins, and restrict condenser airflow. Use a

flashlight to determine if dirt or debris has collected between

coil sections. Clean coil as follows:

1. Turn off unit power.

2. Use a garden hose or other suitable equipment to flush

coil from the outside to remove dirt. Be sure to flush all

dirt and debris from drain holes in the base of unit. Fan

motors are waterproof.

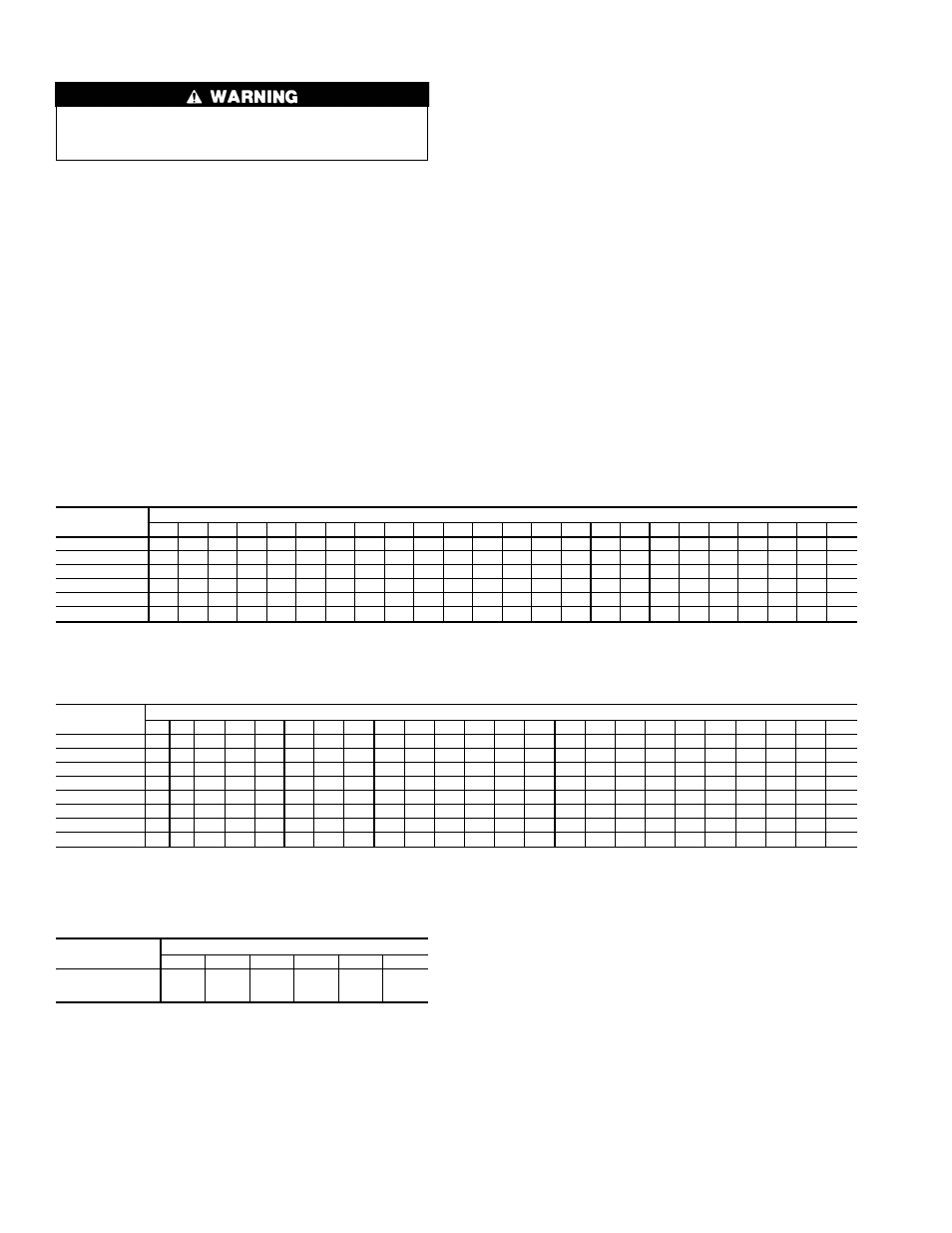

Table 6A — Required Liquid Line Temperature (F) — English (At Service Valve)

REQUIRED

SUBCOOLING (F)

LIQUID PRESSURE AT SERVICE VALVE (PSIG)

134

141

148

156

163

171

179

187

196

205

214

223

233

243

253

264

274

285

297

309

321

331

346

359

0

76

79

82

85

88

91

94

97

100

103

106

109

112

115

118

121

124

127

130

133

136

139

142

145

5

71

74

77

80

83

86

89

92

95

98

101

104

107

110

113

116

119

122

125

128

131

134

137

140

10

66

69

72

75

78

81

84

87

90

93

96

99

102

105

108

111

117

120

123

126

129

129

132

135

15

61

64

67

70

73

76

79

82

85

88

91

94

97

100

103

106

109

112

115

118

121

124

127

130

20

56

59

62

65

68

71

74

77

80

83

86

89

92

95

98

101

104

107

110

113

116

119

122

125

25

51

54

57

60

63

66

69

72

75

78

81

84

87

90

93

96

99

102

105

108

111

114

117

120

Table 6B — Required Liquid Line Temperature (C) — SI (At Service Valve)

REQUIRED

SUBCOOLING (C)

LIQUID PRESSURE AT SERVICE VALVE (PSIG)

911

969

1030

1061

1121

1186

1219

1286

1360

1397

1471

1547

1588

1671

1755

1800

1885

1976

2026

2125

2222

2264

2379

2475

0

24

26

28

29

31

33

34

36

38

39

41

43

44

46

48

49

51

53

54

56

58

59

61

63

2

22

24

26

27

29

31

32

34

36

37

39

41

42

44

46

47

49

51

52

54

56

57

59

61

4

20

22

24

25

27

29

30

32

34

35

37

39

40

42

44

45

47

49

50

52

54

55

57

59

6

18

20

22

23

25

27

28

30

32

33

35

37

38

40

42

43

45

47

48

50

52

53

55

57

8

16

18

20

21

23

25

26

28

30

31

33

35

36

38

40

41

43

45

46

48

50

51

53

55

10

14

16

18

19

21

23

24

26

28

29

31

33

34

36

38

39

41

43

44

46

48

49

51

53

12

12

14

16

17

19

21

22

24

26

27

29

31

32

34

36

37

39

41

42

44

46

47

49

51

14

10

12

14

15

17

19

20

22

24

25

27

29

30

32

34

35

37

39

40

42

44

45

47

49

Table 7 — Recommended Compressor Oils

RECOMMENDED

OIL

UNIT 38HDL

018

024

030

036

048

060

3GS

Calumet RO-15

Sontex 200LT

•

•

•

•

•

•

•

10