Replacing the manifold/burner assembly, Warning, Explosion hazard – Kenmore 153.33114 User Manual

Page 32: Piezoelectric igniter system

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Replacing the Manifold/Burner Assembly

^WARNING

10

.

Explosion Hazard

• Tighten both manifold door screws securely.

•

Remove any fiberglass between gasket

and combustion chamber.

•

Replace viewport if glass is missing or

damaged.

•

Replace manifold component block if missing

or removed.

•

Replace door gasket if damaged.

•

Failure to follow these instructions can result

in death, explosion, or fire.

1. Check the door gasket for damage or imbedded debris

prior to installation.

2. Inspect the view port for damage and replace as required.

3.

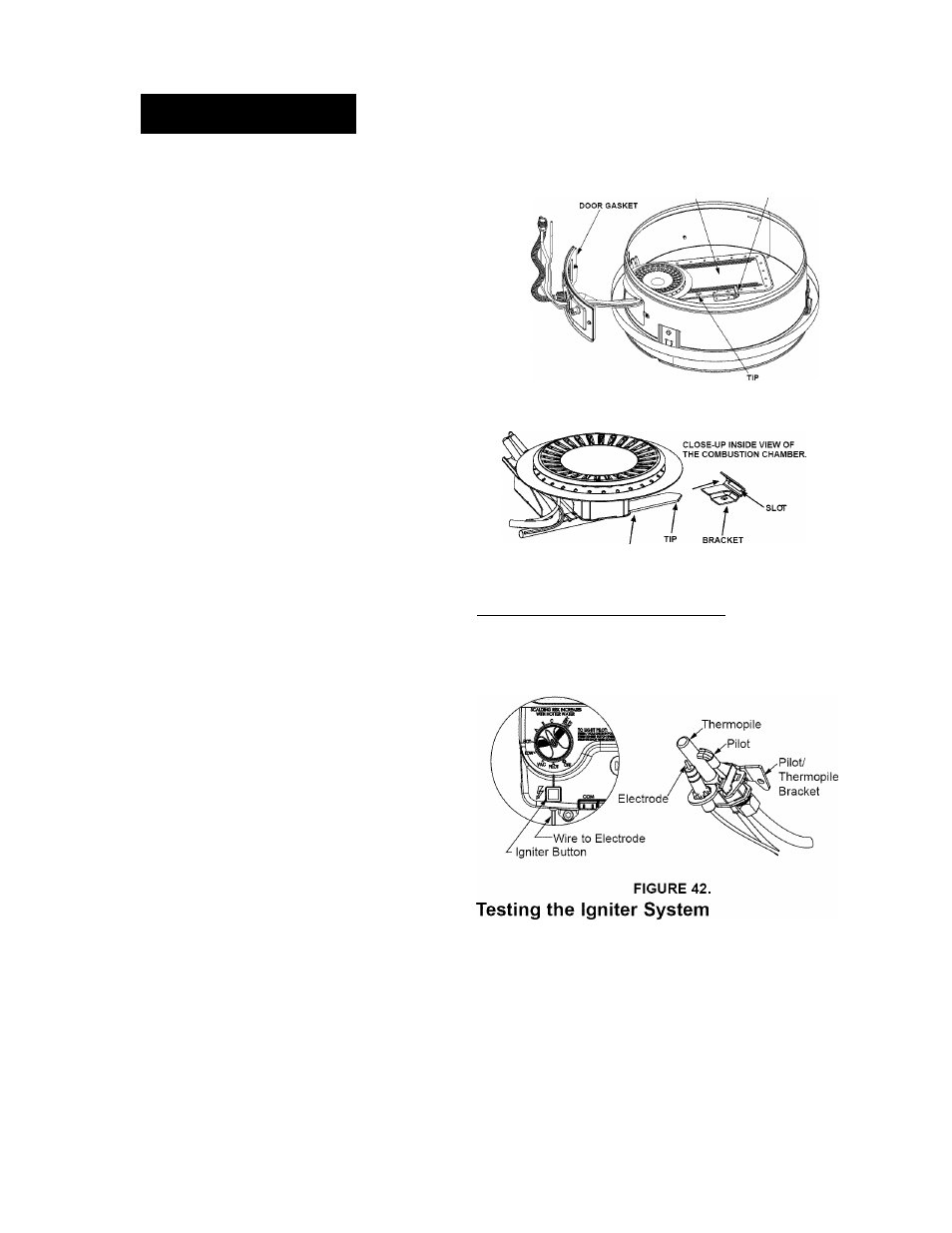

Insert the manifold/burner assembly into the burner

compartment, making sure that the tip of the manifold tube

engages in the slot of the bracket inside the combustion

chamber (Figures 40 & 41).

4.

Inspect the door gasket and make sure there is no

fiberglass insulation between the gasket and the

combustion chamber.

5.

Tighten the two screws which secure the burner/

manifold assembly to the combustion chamber.

There should be no space between the gasket part

of the manifold door and combustion chamber.

IMPORTANT:

Do not operate the water heater if the door

gasket does not create a seal between the manifold door

and the combustion chamber.

6. Reconnect the manifold tube (3/4” wrench) and pilot tube

(7/16” wrench) to the gas control valve/thermostat. Do

not cross-thread or apply any thread sealant to the fittings.

IMPORTANT: If you were supplied with a new ferrule nut in

a parts kit, follow these steps:

1.) Install the ferrule nut into the gas valve at the pilot tube

location, hand tight only. 2.) Insert the pilot tube into the

ferrule nut until the tube bottoms out, then tighten the nut

with a 7/16” wrench until the crimp connection seals to the

pilot tube. Continue to tighten until the nut is tight in the gas

valve.

NOTE: L.P. Gas systems use reverse (left-hand) threads on

the manifold tube.

7. Connect the white (-) thermopile wire to the gas control

valve/thermostat. Then connect the red thermal switch

wires to the thermal switch on the on the manifold door.

(Figure 38).

8. Reconnect the igniter wire (Figure 33).

9. Turn on the gas supply to the water heater at the manual gas

shut-off valve (Figure 11).

Follow the lighting instructions on the front of the water

heater. With the main burner lit, check for leaks at

the manifold and pilot connections by brushing on an

approved noncorrosive leak detection solution, or a

mixture of hand dish washing soap and water (one part

soap to 15 parts water) or childrens soap bubble solution.

Bubbles forming indicate a leak. Correct any leak found.

Verify proper operation and then replace the outer door.

FLAME ARRESTOR BRACKET

FIGURE 40.

MANIFOLD TUBE

FIGURE 41.

Piezoelectric Igniter System

The piezoelectric igniter system consists of the igniter button,

electrode, and wire. The pilot is ignited by an electric spark

generated when the igniter button is pressed. (See Figure 42).

Turn off the gas to the water heater at the manual gas shut-off

valve. Watch the electrode tip while activating the igniter. A

visible spark should jump from the electrode. To avoid shock,

do not touch the burner or any metal part on the pilot or pilot

assembly. If no spark is visible, check the wire connections

and make sure the electrode is not broken. Replace the igniter

if defective. Dirt and rust on the pilot or electrode tip can

prevent the igniter spark. Wipe clean with a damp cloth and dry

completely. Rust can be removed from the electrode tip and

metal surfaces by lightly sanding with an emery cloth or fine

grit sandpaper.

32