Now start, Page 5 – Whirlpool 3406449 User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

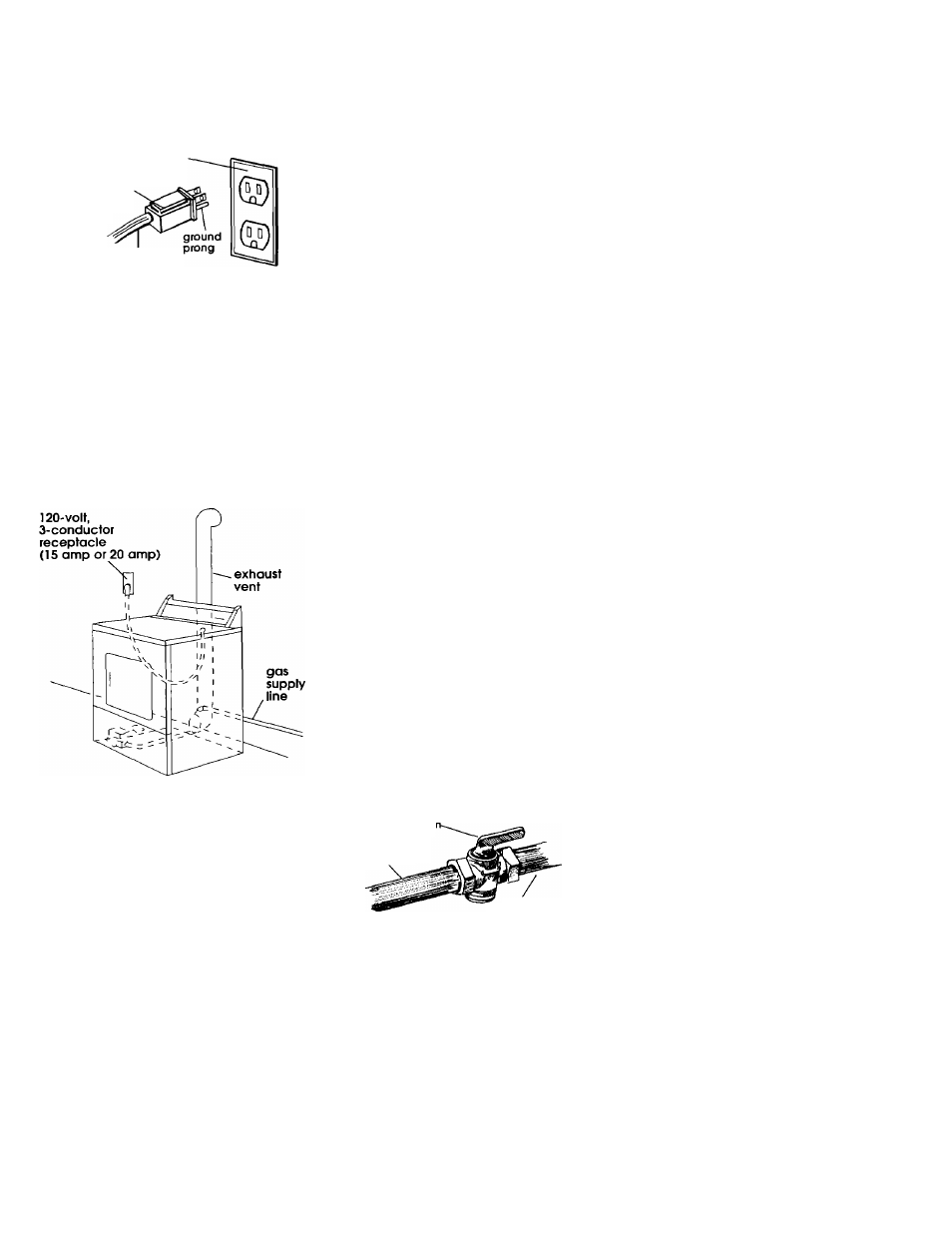

customer to have a properly

grounded, 3-prong wall receptacle

Installed by a qualified electrician. See

Figure 1.

3-prong,

ground-type

wall receptacle

3-prong,

ground

plug

power supply

cord

Figure 1

Copies of the standards listed above may

be obtained from:

‘American Gas Association

1515 Wilson Boulevard

Arlington, Virginia 22209

" National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

Now start...

With dryer in laundry area.

I

■ Put on safety glasses and

gloves. Take tape off front corners of

dryer. Open dryer and remove the

literature and parts packages.

Remove the tape that holds the

drum to the cabinet. (Some dryer

drums are not taped for shipping.)

Move the drum by hand to make

certain all tape has been removed.

Wipe the interior of the drum

thoroughly with a damp cloth.

fcB Take two of the cardboard

corners from the carton and place

them on the floor in back of the

dryer. Firmly grasp the body of the

dryer and gently lay it on its back on

the cardboard corners.

3 ■ With one of the legs in hand,

check the ridges for a diamond

marking. That's how far the leg is

supposed to go into the hole.

4

b

Start to screw the leveling legs

into the holes by hand. (Use a small

amount of liquid detergent to

lubricate the screw threads so it is

easier to turn the legs.) Use a 1-inch

wrench or socket wrench to finish

turning the legs until you reach the

diamond mark.

Stand the dryer up.

Slide dryer onto cardboard or hard-

board before moving across floor to

avoid damaging floor covering.

3 B Move dryer close to final

position. Remove cardboard or

hardboard from under dryer.

6

b

Remove red cap from gas pipe.

Carefully move dryer into final

position. Place level on top of the

dryer, first side to side: then front to

back. If the dryer is not level, adjust

the legs of the dryer up or down until

the dryer is level.

7

B Connect gas supply to dryer. Use

pipe-joint compound resistant to the

action of L.Pgas for gas connections.

If flexible metal tubing is used, check

that there are no kinks.

shutoff valve

"open" positioi

to dryer

gas supply line

6

b

Open the shutoff valve in the

gas supply line.

9

b

Use a brush and liquid detergent

to test all external gas connections

for leaks. Bubbles around connections

will indicate a leak. If a leak appears,

shut off gas valve controls and adjust

connections. Then check connections

again. NEVER TEST FOR GAS LEAKS

WITH A FLAME. Close the access

panel.

All connections must be wrench-

tightened.

10

.

I To exhaust dryer, see "Exhaust

requirements," Pages 2-3. Connect

exhaust vent to exhaust hood. Use

duct tape to seal all joints in the

exhaust vent. Use caulking to seal

exterior wall opening around exhaust

hood.

11

b

Plug power supply cord into

grounded outlet.

12

.

Insert user card and push

START button to start dryer to remove

air from the gas supply line. Using a

full heat cycle (not the air cycle), let

the dryer run for at least five minutes.

If the burner does not ignite and you

can feel no heat inside the dryer, shut

off the dryer for five minutes. Check

that all gas supply valve controls are

in "ON" position and that the power

supply cord is plugged in. Repeat the

five-minute test.

Note: Dryer door must be closed for

dryer to operate. When door is open,

dryer stops, but timer continues to

run. To restart dryer, close door and

push START button.

Page 5