Throttle servo – Carl Goldberg GBGA1043 User Manual

Page 15

15

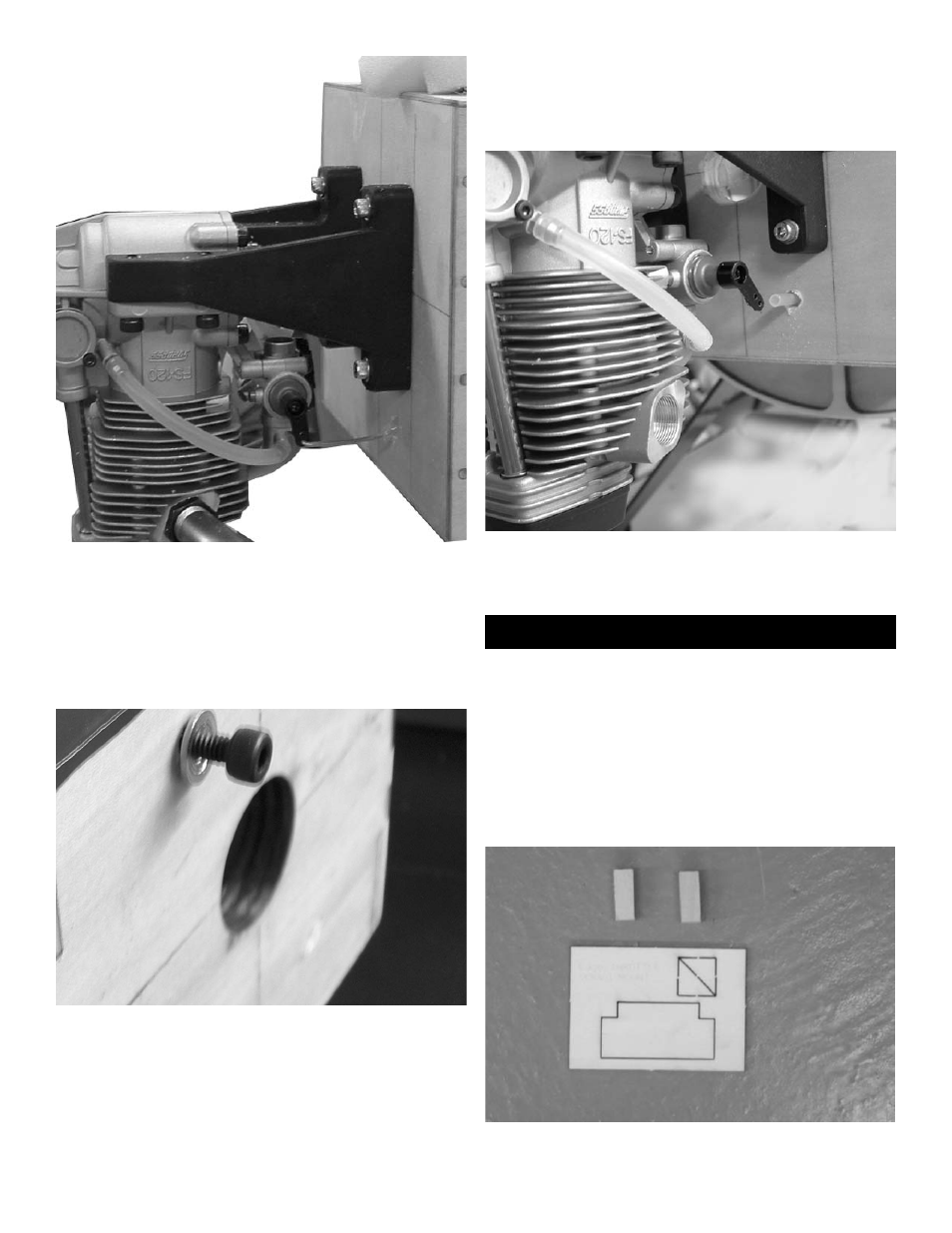

6.

Seat the blind nut by using one of the 4mm

bolts and a flat washer without the mounts.

Pull the blind nut firmly into the firewall using

the screw. Repeat for the other 3 screws.

7.

Bolt the engine in place being sure to use lock-

tite on all the screws.

8.

Drill a 9/64” hole in line with the throttle output

arm on your engine and insert the nylon tube for the

throttle pushrod.

Throttle Servo

1. Collect the following items:

(1) e-z servo connector

(1) Laser cut plywood mount

(1) 2-56 threaded one end pushrod

(1) 2-56 clevis

(1) clevis retainer

5.

With the motor on the mounts, center the

mounts on the two line you drew on the fire-

wall.

Mark the location of the holes and drill a .160

diameter hole at each location.

Open the hole up with a .200 diameter drill (the

shoulder of the blind nut is .200)

- GBGQ1296 (12 pages)

- GBGA1079 (25 pages)

- GPMA0963 Cub (33 pages)

- GBGA1023 (12 pages)

- GBGA1069 (29 pages)

- GPMA1956 Eagle 2 ARF (40 pages)

- GPMA0955 EAGLE 2 (59 pages)

- GBGA1080 (9 pages)

- GBGA1046 (21 pages)

- GBGA1045 (21 pages)

- GBGA1040 (16 pages)

- GBGA0040 (40 pages)

- GBGA1082 (10 pages)

- GBGA0055 (44 pages)

- GBGA1041 (20 pages)

- GBGA1070 (17 pages)

- GBGA1078 (23 pages)

- GBGA0050 (26 pages)

- GPMA1940 EP Falcon ARF (16 pages)

- GBGA0057 (60 pages)

- GPMA1960 Gentle Lady Glider ARF (16 pages)

- GPMA0960 Gentle Lady (21 pages)

- GBGA1091 (15 pages)

- GBGA1042 (9 pages)

- GBGA1019 (13 pages)

- GBGA1072 (14 pages)

- GBGA1075 (18 pages)

- GPMP1020 Mini Hold'em Electric Cradle (2 pages)

- GBGP0105 (10 pages)

- GBGA1090 (16 pages)

- GBGA1064 (24 pages)

- GBGA1088 (30 pages)

- GPMA1926 Monster Pitts Electric ARF (17 pages)

- GBGA1058 (9 pages)

- GBGA1087 (16 pages)

- GBGA1092 (24 pages)

- GBGA1085 (19 pages)

- GPMA1993 Skylark 70 Sport ARF (18 pages)

- GPMA1959 Sophisticated Lady Glider ARF (20 pages)

- GBGA0059 (32 pages)

- GPMA1967 Sr. Falcon ARF (21 pages)

- GBGA1089 (19 pages)

- GBGA1067 (19 pages)

- GBGA0067 (39 pages)

- GBGP0108 (4 pages)