AAF International SAH User Manual

Page 9

9

! WARNING: The housing is not designed to support the weight of

inlet and outlet ducts. All ducts shall be supported independently of

the housing. Any attempt to support the ducts from the housing may

result in serious equipment damage and severe personal injury.

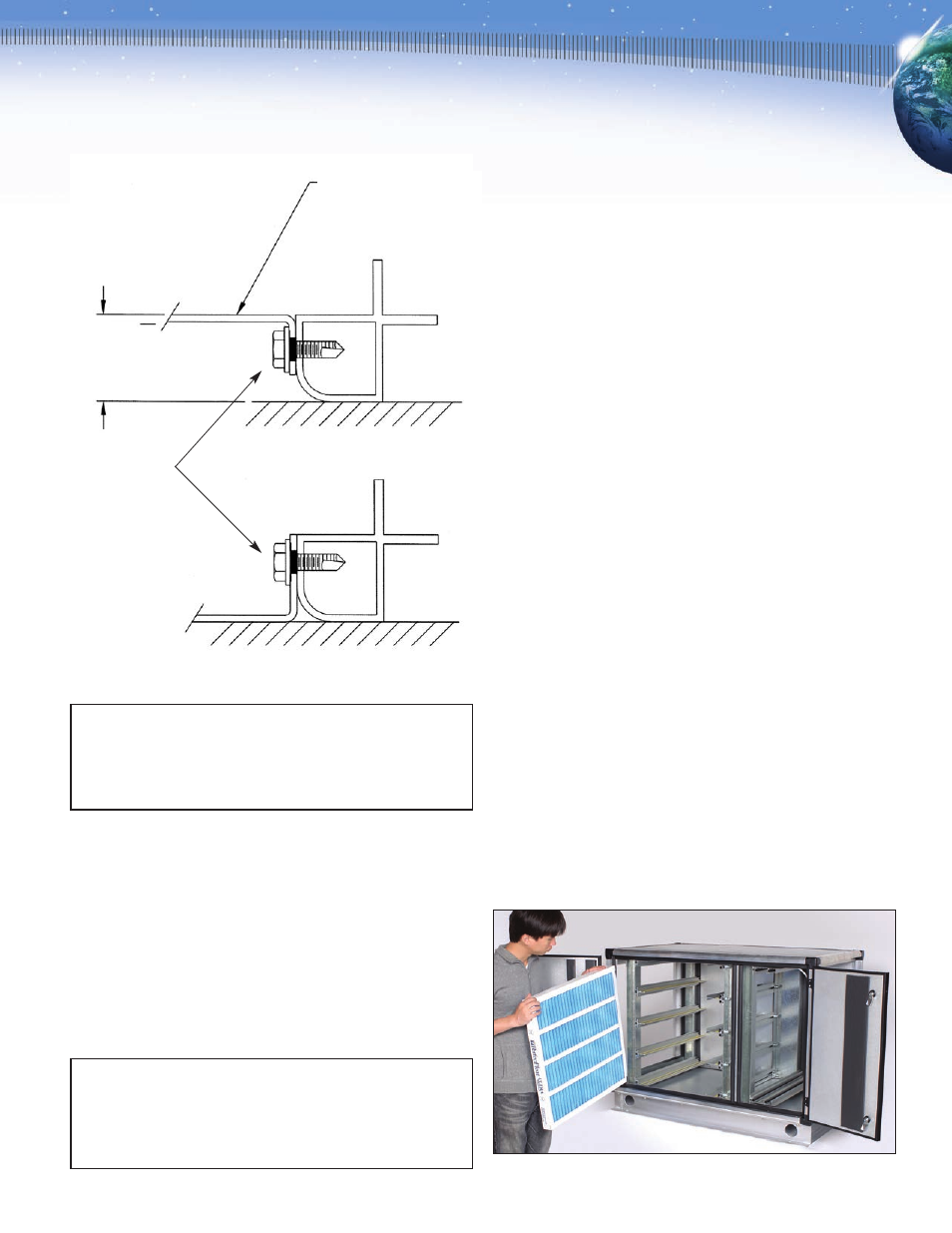

3.4.4 Sealing the Inlet and Outlet Duct Connections: Provide

continuous gaskets, or caulk generously, between the flanges of the

connecting ducts and the housing to prevent air leaks.

Provision of the inlet and outlet ducts, the connecting hardware,

and the gaskets or caulk will be the responsibility of the installer or

others. These items will not be supplied by AAF unless noted

specifically in the AAF quotation and in the accepted customer

purchase order. Any caulk used shall be a long life, flexible,

non-drying caulking material. The caulk supplier shall ensure that

the caulk shall meet the customer specifications for the application

in which it is being used.

CAUTION

Many installations prohibit the use of certain caulking materials such as

Silicone. The use of materials containing VOCs should also be avoided

as they may have a negative effect on the life of the gas-phase filters.

3.5 Preparation for Filter Installation: In order to maximize the life

of the gas-phase chemical filters and the particulate filters it is

recommended that filter installation be the final installation task before

start-up and commissioning of the system. In preparation for filter

installation it is recommended that the following be completed:

– Completely clean the system to remove all construction debris

and dirt, sweep, and vacuum to remove visible dirt.

– Damp wipe all surfaces to remove dust.

– Finalize and complete all caulking in the system.

– Finalize and complete all painting in the system.

It is recommended that all cleaning materials and paints used in the

system be free of solvents. If this is unavoidable it is recommended

that sufficient time be allowed for complete drying to occur and for the

VOCs to disperse before installing the filters. This process can be

accelerated by “blowing down” the system, i.e. operating the fan

without the filters to ventilate the system. It is recommended that a

blanket-style construction filter be installed at the inlet to the system to

prevent construction dust from being drawn into the system. Consult

with your AAF representative to obtain an appropriate product. Also,

before “blowing down” the system check that it is safe to operate the

fan without the pressure load of the gas-phase chemical filters.

Consult the AAF submittal drawing for pressure information.

3.6 Prefilter Installation: It is highly recommended that prefilters be

used to prevent the build-up of lint and dust on the face of the gas-phase

chemical filters. If prefilters have not been provided elsewhere in the

system ahead of the gas-phase filters they should be included in the

Side Access Housing.

Install the prefilters as shown in the sequence shown below and at the

top of page 10. The standard Side Access Housings are designed to

accept 2" deep prefilters only. For best results, AAF recommends the use

of the MERV 7 rated PerfectPleat

®

. The tracks are spaced and sized to

accept 24" x 24", 12" x 24" and 24" x 12" nominal ASHRAE style filters.

Place the prefilter into the prefilter track with the pleats arranged

vertically. However, it may be necessary when installing some

half-size filters to arrange the pleats horizontally.

Figure 4

Inlet or Outlet Duct Wall,

by others

1

-

3

⁄

1 6

"

[30 mm]

Duct Connection

Duct Connection Alternate Method

Step 1: Insert the prefilter into the track.

Connecting hardware,

by others