Hangar 9 33% Pawnee 80cc ARF (3 Boxes) User Manual

Page 9

9

Hangar 9 33% Pawnee 80cc ARF

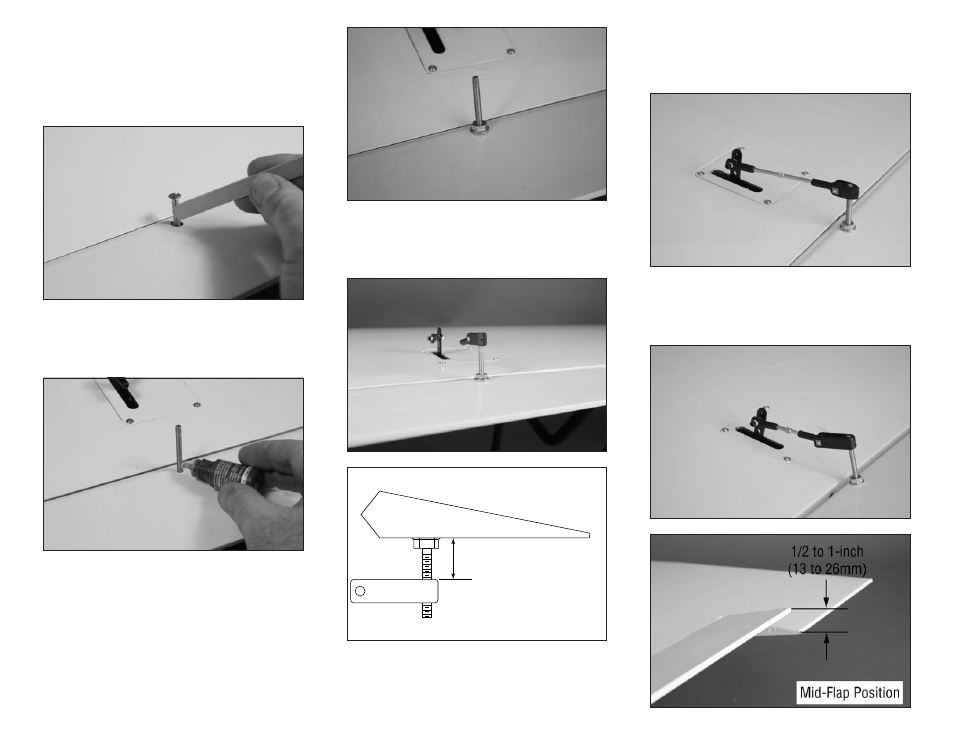

20. Slide the 8-32 x 2

1

/

4

-inch countersunk

machine screw into the hole in the aileron. Mix a small

amount of 30-minute epoxy and apply it to the last 1/2-

inch (13mm) of the screw. Once the screw is in position,

Use isopropyl alcohol and a paper towel to remove any

excess epoxy.

21. Apply a drop of threadlock on the screw near

the aileron surface. Use an 11/32-inch open-end wrench to

tighten the 8-32 flanged nut against the wing to secure the

position of the screw.

22. Thread the short control horn on the screw

for the aileron until it is 1

1

/

8

-inch (29mm) from the control

surface as shown. Use the short control horn for the aileron,

and the long control horn for the flaps.

*Drawing not to scale

1

1

/

8

-inch (28.5mm)

23. Repeat Steps 2 through 22 to install the

remaining aileron servos, as well as the flap servos.

24. Install the 4-40 x 3-inch adjustable link between the

control horn and ball end. With the servo centered, adjust

the link so the aileron is centered as well. Install the linkage

for both ailerons at this time.

25. Use a 4-40 x 2-inch adjustable link for the flap

servo installation. Adjust the linkage to achieve the mid-flap

position as shown. The servo horn can be angled toward the

leading edge to achieve mechanical differential.