Hangar 9 Twist 40 ARF Version 2 User Manual

Page 11

20

21

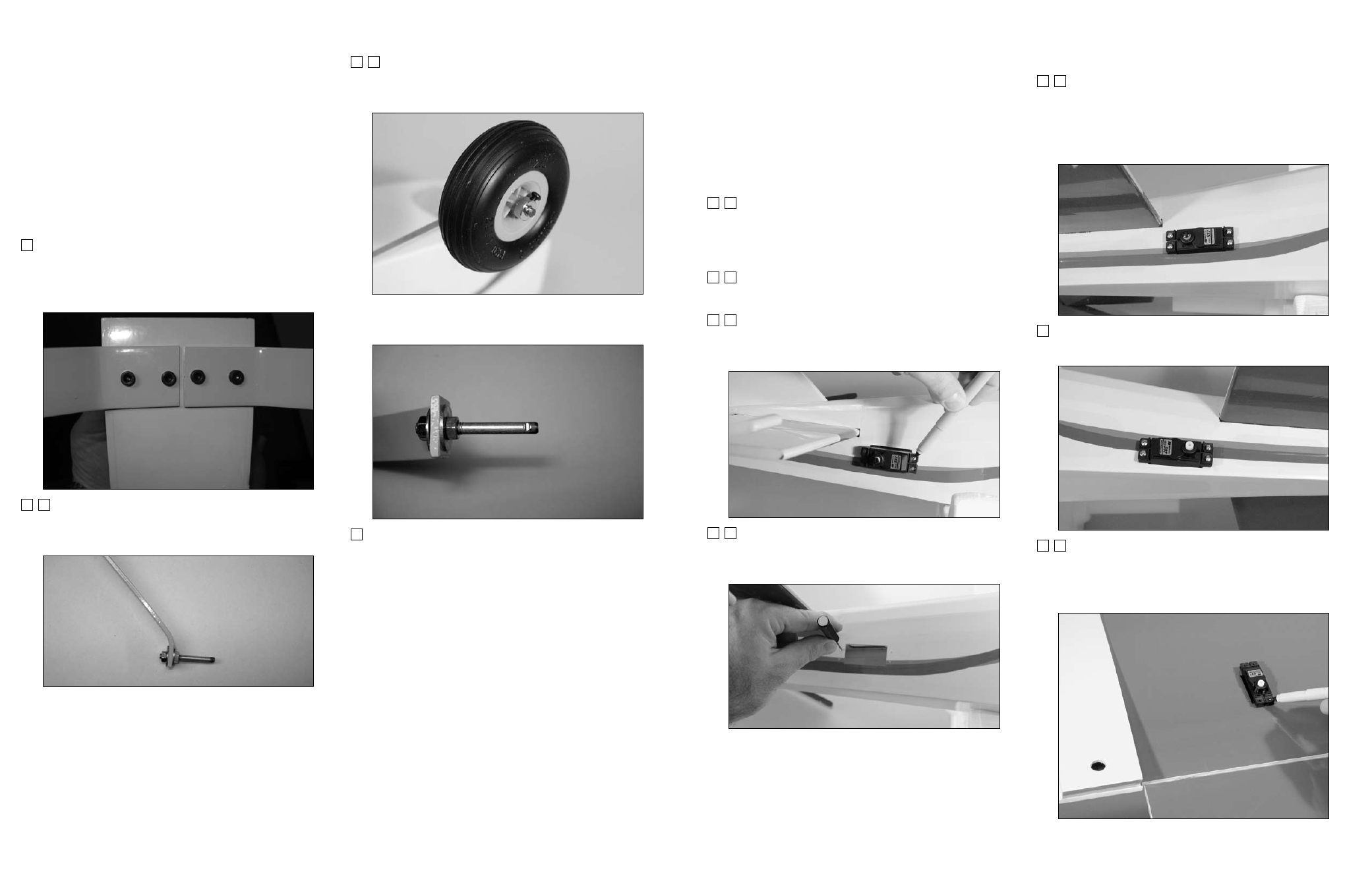

Section 11: Landing Gear Installation

Section 12: Radio Installation

Required Parts

Fuselage assembly

• 2 3/4-inch wheel (2)

•

4mm x 25mm axle with nut (2)

• 1-inch wheel

•

4mm wheel collar (2)

• Landing gear

•

4mm x 20mm screw (4)

• Grub screw (2)

•

Required Tools and Adhesives

Drill

• Drill bits: 1/16-inch,

•

1/8-inch, 5/32-inch

Phillips screwdriver (large) • Hex wrench (included in kit)

•

Step 1

Locate the main landing gear and four 4mm x 20mm screws.

Attach the main landing gear using the screws. The angle on

the gear should be toward the rear of the plane.

Step 2

Attach the axle to each landing gear leg with the included two

nuts and washers. Use threadlock when assembling the axle.

Step 3

Attach the wheel to the axle using a wheel collar and grub

screw.

Hint: File a flat area where the screw contacts the axle, to

help prevent the screw from loosening during flight.

Step 4

Repeat Steps 2 and 3 for the remaining wheel.

Required Parts

Fuselage assembly

• Wing assembly

•

Servo with hardware (5)

•

Required Tools and Adhesives

Drill

• Drill bit: 1/16-inch

•

Phillips screwdriver (small) • Servo extension –

•

12-inch (2)

Step 1

Install the recommended servo hardware (grommets and eye-

lets) supplied with your radio system onto five servos (elevator,

rudder, throttle, and aileron (2)).

Step 2

Temporarily install the rudder servo.

Step 3

Mark the locations for the servo screws using

a felt-tipped pen.

Step 4

Remove the servo and drill the holes for the servo mounting

screws using a 1/16-inch drill bit.

Hint: Place a drop of thin CA onto each screw hole to harden

the wood around the hole. Allow the CA to fully cure before

installing the servos.

Step 5

Attach a 12-inch servo extension onto the rudder servo. Use

your favorite method to secure the extension to prevent it from

coming loose during flight. Secure the rudder servo using the

screws provided with the servo.

Step 6

Repeat Steps 1 through 5 for the elevator servo.

Step 7

Temporarily install the aileron servo and mark

the locations for the servo screws using a

felt-tipped pen.