4 | compressor assembly – GEA Bock FK50 User Manual

Page 13

13

09704-09.2013-DGbFIT

rCn

D

GB

F

I

TR

CN

4| Compressor assembly

4.7 Pipes

Pipes and system components must be clean and dry inside and free of scale, swarf and layers of

rust and phosphate. Only use air-tight parts.

Lay pipes correctly. Suitable vibration compensators must be provided to prevent pipes being

cracked and broken by severe vibrations.

Ensure a proper oil return.

Keep pressure losses to an absolute minimum.

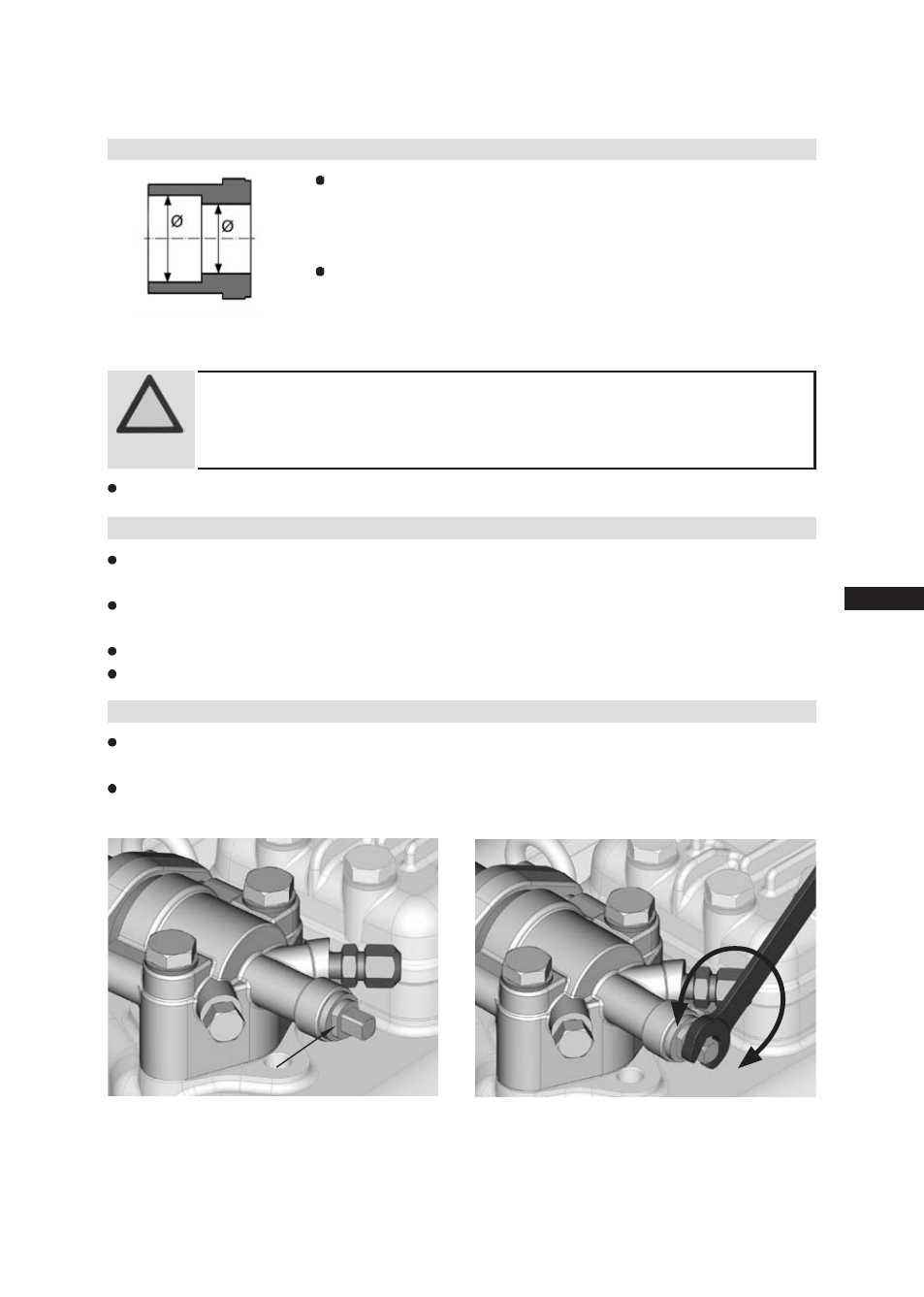

The

discharge and suction line valves have stepped internal

diameters, enabling the use of pipes with standard millimetre and

inch dimensions. The depth of pipe insertion will depend on the

dimension.

The connection diameters of the shut-off valves are designed for

maximum compressor output.

The required pipe cross-section

must be matched to the capacity. The same applies for

non-return valves.

Fig. 13: Stepped

internal diameters

4.6 Pipe connections

4.8 Operating the shut-off valves

Before opening or closing the shut-off valve, release the valve spindle seal by approx. ¼ of a turn

counter-clockwise.

After activating the shut-off valve, re-tighten the adjustable valve spindle seal clockwise.

Fig. 14

Fig. 15

ATTENTION! Overheating can damage the valve.

Therefore, remove the pipe supports from the valve before

soldering.

Solder only using inert gas to inhibit oxidation products.

The required tightening torque for the flange connection is 60 Nm.

Valve spindle seal

Release

Tighten