8 | maintenance – GEA Bock HGZ7 User Manual

Page 31

D

GB

F

E

31

09726-11.2014-DGbF

8| Maintenance

Only use genuine GEA Bock spare parts!

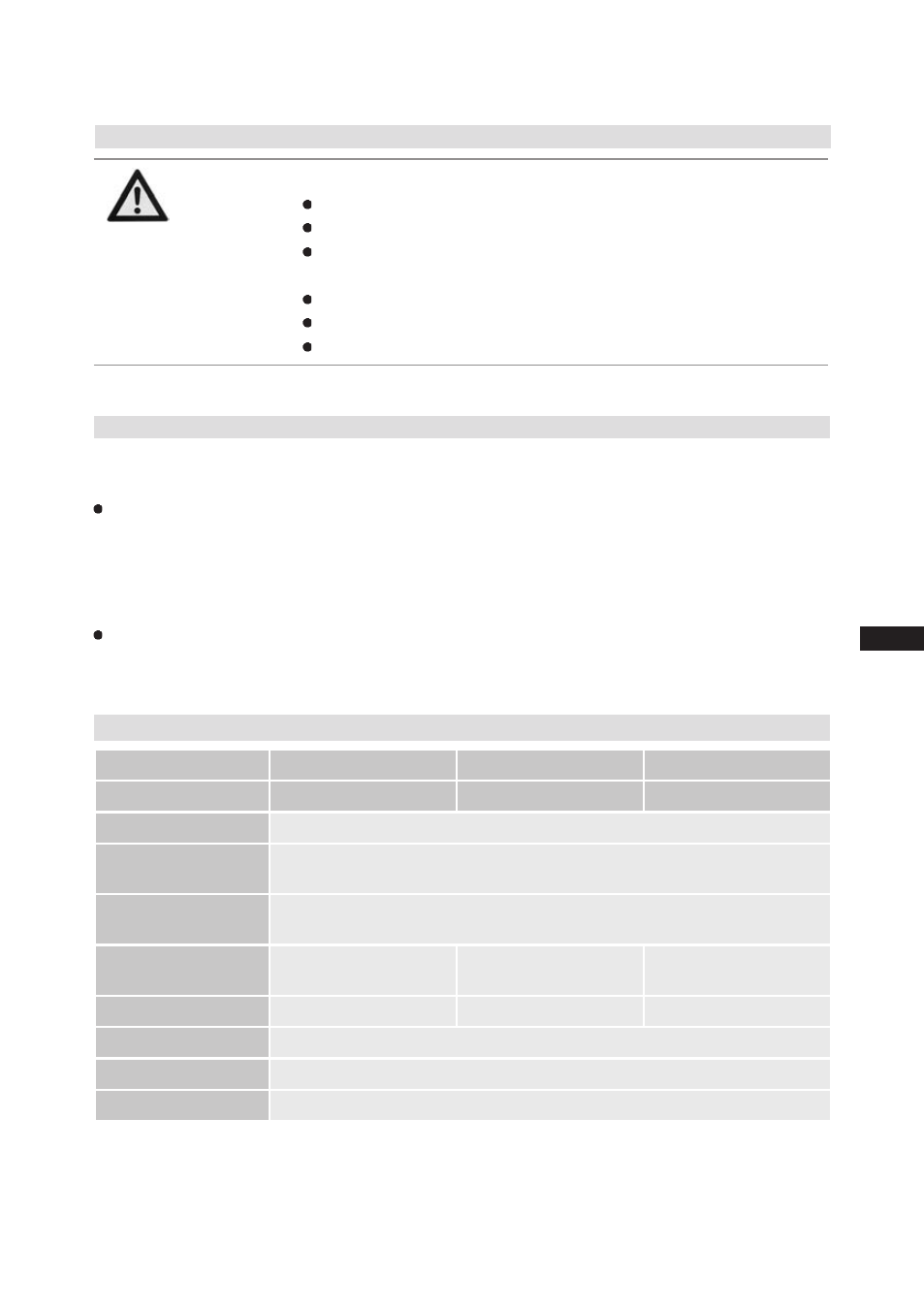

8.3 Recommended spare parts

HGZ7 / ...

1620-4

1860-4

2110-4

Designation

Item No.

Item No.

Item No.

Set of gaskets kit

80197

Valve plate kit

low pressure side LP

80193

Valve plate kit

high pressure side HP

80194

Piston-connecting

rod kit

08995

08996

80112

Piston kit

80042

80048

80106

Connecting rod kit

80306

Oil pump kit

80116

Oil sump heater kit

08426

8.1 Preparation

WARNING

Before starting any work on the compressor:

Switch off the compressor and secure it to prevent a restart.

Relieve compressor of system pressure.

Prevent air from infiltrating the system!

After maintenance has been performed:

Connect safety switch.

Evacuate compressor.

Release switch lock.

8.2 Work to be carried out

In order to guarantee optimum operational reliability and service life of the compressor,

we

recommend carrying out servicing and inspection work at regular intervals:

Oil change:

-

not mandatory for factory-produced series systems.

-

for field installations or when operating near the application limit: for the first time after 100

to 200 operating hours, then approx. every 3 years or 10,000 - 12,000 operating hours.

Dispose of used oil according to the regulations; observe national regulations.

Annual checks: Oil level, leak tightness, running noises, pressures, temperatures, function of

auxiliary devices such as oil sump heater, pressure switch.