6 | electrical connection, Yyy y/yy – GEA Bock HGZ7 User Manual

Page 24

24

D

GB

F

E

09726-11.2014-DGbF

400 V

Direktstart YY

Teilwicklungsstart Y/YY

1V1

1W1

1U1

2W1

2V1

2U1

L3

L2

L1

L3

L2

L1

L3

L2

L1

1V1

1W1

1U1

2W1

2V1

2U1

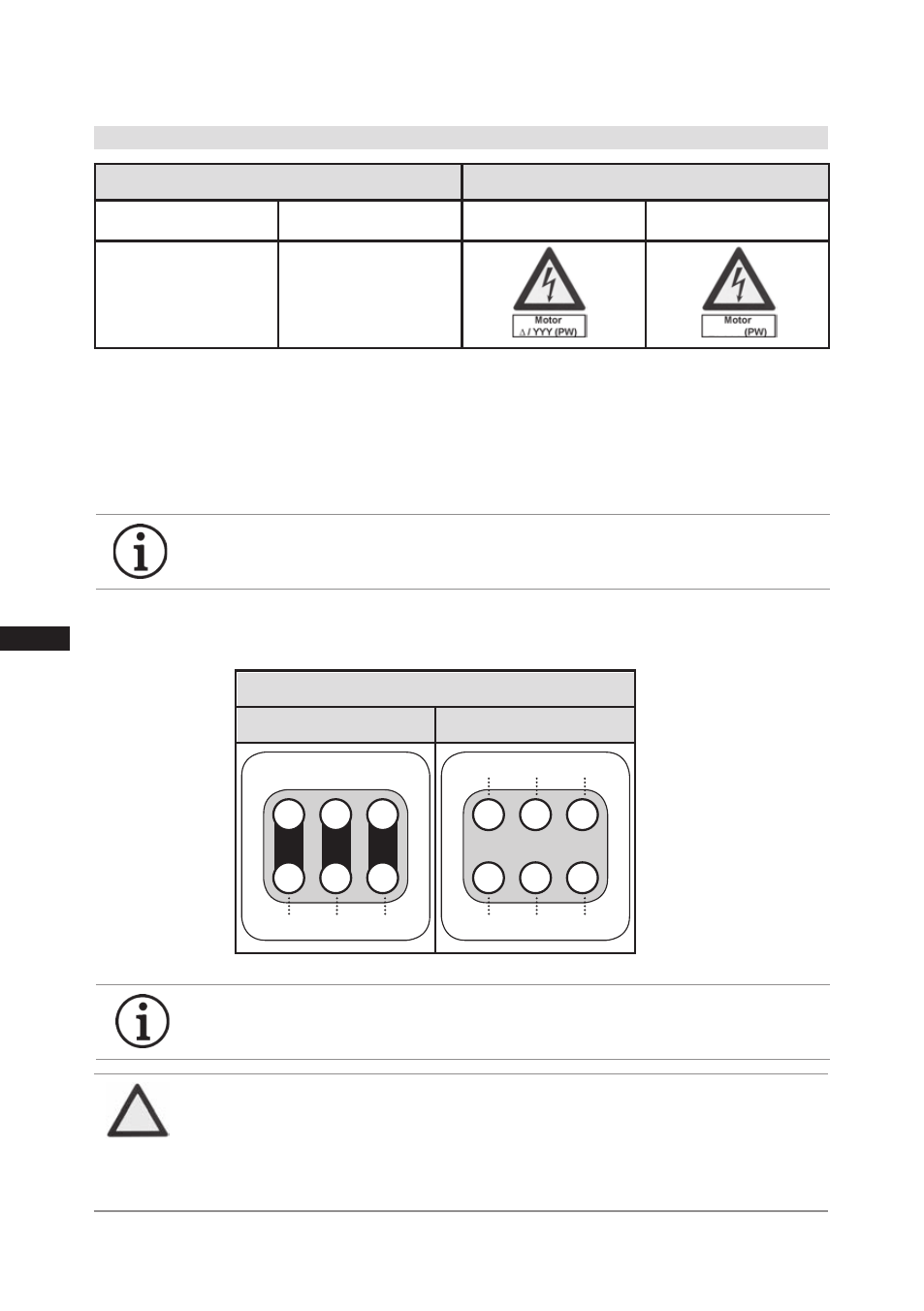

Direct start

Part winding start

6| Electrical connection

6.3 Standard motor, design for direct or partial winding start

The motor is wired for direct start (YYY resp. YY) at the factory. For part winding start

Δ/YYY resp.

Y/YY the bridges must be removed and the motor feed line connected according to the circuit diagram:

INFO

A mechanical unloaded start with bypass solenoid valve is

not required.

Designation on the name plate

Sticker on the terminal box

until A018

from A040

until A018

from A040

∆/YYY

Y/YY

Y/YY

Compressors with this marking are suitable for direct or partial winding start. The motor winding is

subdivided into two parts:

Until type code A018: Part winding 1 = 60% and part winding 2 = 40%. This winding division

reduces the start-up current needed for a part winding start to approx. 65% of that for a direct start.

From type code A040: Part winding 1 = 50% and part winding 2 = 50%. This winding division

reduces the start-up current needed for a part winding start to approx. 50% of that for a direct start.

ATTENTION Failure to do this results in opposed rotary fields and results in

damage to the motor. After the motor starts up via partial winding

1, partial winding 2 must be switched on after a maximum delay

of one second . Failure to comply can adversely affect the service

life of the motor.

INFO

When testing coils with resistance tester, please note that partial

winding 1 and partial winding 2 are wired internally in HGZ7.