7 | maintenance – GEA Bock HG7 User Manual

Page 26

26

D

GB

F

E

I

Ru

09706-01.2015-DGbFEIRu

7.1 Preparation

7.2 Work to be carried out

7| Maintenance

In order to guarantee optimum operational reliability and service life of the compressor,

we

recommend carrying out servicing and inspection work at regular intervals:

Oil change:

-

not mandatory for factory-produced series systems.

-

for field installations or when operating near the application limit: for the first time after 100

to 200 operating hours, then approx. every 3 years or 10,000 - 12,000 operating hours.

Dispose of used oil according to the regulations; observe national regulations.

Annual checks: Oil level, leak tightness, running noises, pressures, temperatures, function of

auxiliary devices such as oil sump heater, pressure switch.

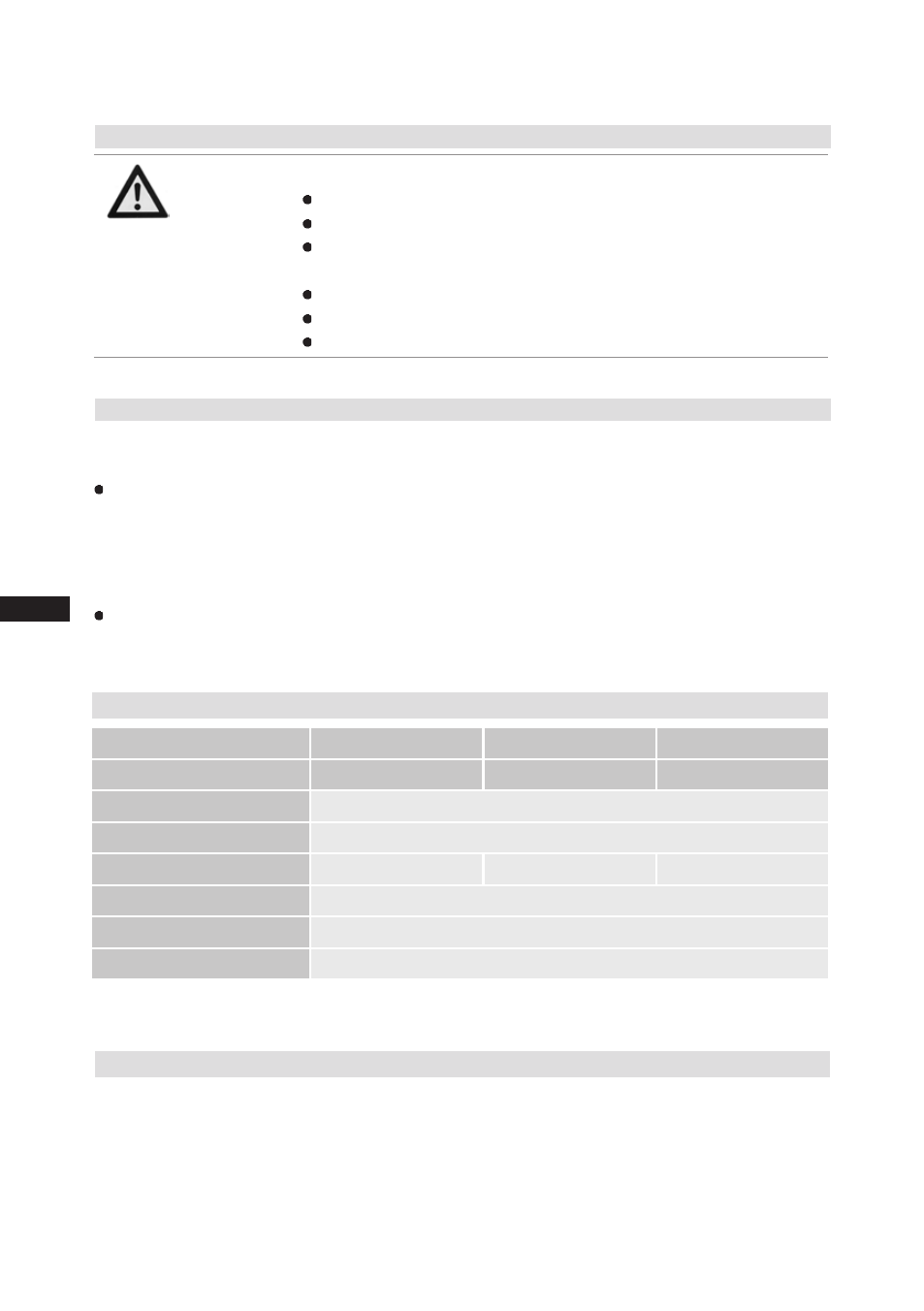

WARNING

Before starting any work on the compressor:

Switch off the compressor and secure it to prevent a restart.

Relieve compressor of system pressure.

Prevent air from infiltrating the system!

After maintenance has been performed:

Connect safety switch.

Evacuate compressor.

Release switch lock.

Only use genuine GEA Bock spare parts!

7.3 Spare part recommendation

HG7 / ...

1620-4 (S)

1860-4 (S)

2110-4 (S)

Designation

Item No.

Item No.

Item No.

Set of gaskets

80094

Valve plate kit

08498

Set piston/connecting rod

08995

08996

80112

Set connecting rod

08306

Oil pump set

80116

Oil sump heater set 230 V ~

08426

Available accessories can be found on the Internet at www.gea.com

7.4 Accessories