5 | electrical connection, Yyy y/yy – GEA Bock HG7 User Manual

Page 16

16

D

GB

F

E

I

Ru

09706-01.2015-DGbFEIRu

400 V

Direktstart YY

Teilwicklungsstart Y/YY

1V1

1W1

1U1

2W1

2V1

2U1

L3

L2

L1

L3

L2

L1

L3

L2

L1

1V1

1W1

1U1

2W1

2V1

2U1

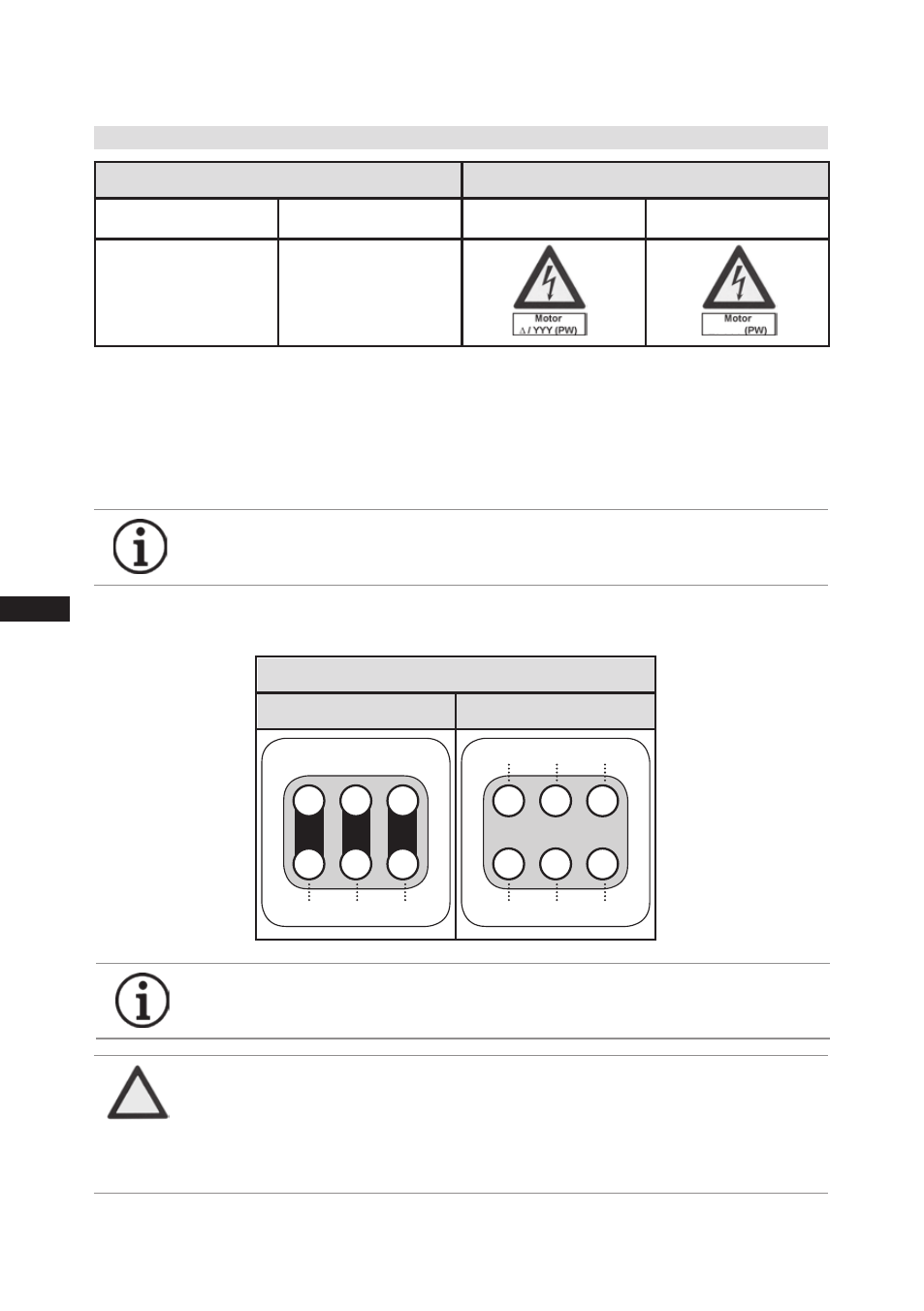

Direct start

Part winding start

The motor is wired for direct start (YYY resp. YY) at the factory. For part winding start

Δ/YYY resp.

Y/YY the bridges must be removed and the motor feed line connected according to the circuit diagram:

5.3 Standard motor, design for direct or part winding start

5| Electrical connection

INFO

A mechanical unloaded start with bypass solenoid valve is

not required.

ATTENTION Failure to do this results in opposed rotary fields and results in

damage to the motor. After the motor starts up via partial winding

1, partial winding 2 must be switched on after a maximum delay

of one second . Failure to comply can adversely affect the service

life of the motor.

INFO

When testing coils with resistance tester, please note that partial

winding 1 and partial winding 2 are wired internally in HG7.

Designation on the name plate

Sticker on the terminal box

until A039

from A040

until A039

from A040

∆/YYY

Y/YY

Y/YY

Compressors with this marking are suitable for direct or partial winding start. The motor winding is

subdivided into two parts:

Until type code A039: Part winding 1 = 60% and part winding 2 = 40%. This winding division

reduces the start-up current needed for a part winding start to approx. 65% of that for a direct start.

From type code A040: Part winding 1 = 50% and part winding 2 = 50%. This winding division

reduces the start-up current needed for a part winding start to approx. 50% of that for a direct start.