3 factors with an impact on grinding, 1 running time (grinding duration), Using the planetary mill – FRITSCH PULVERISETTE 23 User Manual

Page 22

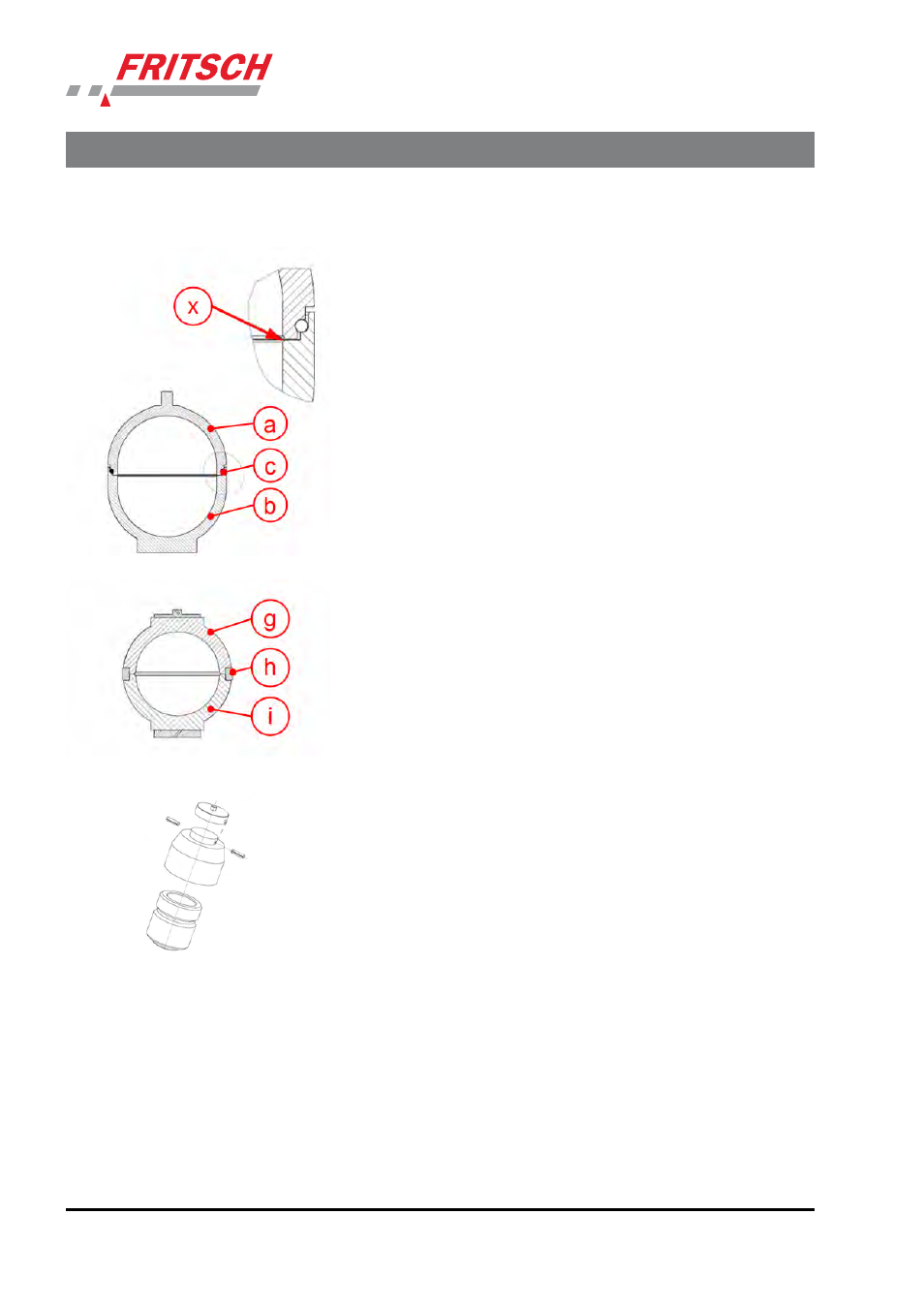

Stainless steel and tempered steel:

a

Grinding bowl lid

b Grinding bowl

c

O-ring

x

A burr can form in this position!

n

The bowl sealing surfaces must be clean.

n

A burr can form on the inner edge of the stainless grinding bowl and

lid after a lengthy grinding time. This burr has to be removed at an

early stage with a scraper or fine emery paper (see also Ä Chapter 8

n

Check the O-ring (c) of the lid seal for damage and proper insertion.

The inner diameter of the O-ring is a bit smaller than the outer diam-

eter of the base of the grinding bowl lid (a). The O-ring must there-

fore be stretched in order to attach it.

n

Place the lid (a) with the seal attached (c) vertically onto the bowl

(b); do not force it.

Zirconium oxide:

The seal is created by grinding the surfaces of the lid (g) and the bowl (i)

to lie perfectly flush. Use a centre ring (h) to align both parts.

PTFE (Teflon):

The seal is created by grinding the surfaces of the lid and the bowl to lie

perfectly flush. In addition, they are also screwed together. These bowls

cannot be used for grinding hard sample materials. They are used to

solubilise soft sample materials or mix and homogenise sample mate-

rials. The bowl can be cooled in liquid nitrogen.

6.3 Factors with an impact on grinding

6.3.1 Running time (grinding duration)

A longer grinding time will increase the percentage of fine material. To

reduce the grinding time, you can use a grinding bowl and grinding balls

with a higher density, and thus a higher impact energy.

Using the planetary mill

- 22 -