6 using the planetary mill, 1 choice of grinding bowls and grinding balls, 1 size of the grinding balls – FRITSCH PULVERISETTE 23 User Manual

Page 19: 6using the planetary mill, Using the planetary mill

6

Using the planetary mill

6.1 Choice of grinding bowls and grinding balls

CAUTION!

If the grinding elements used are not genuine accessories,

we assume no guarantee and exclude all liability for

damage to the device or for personal injury.

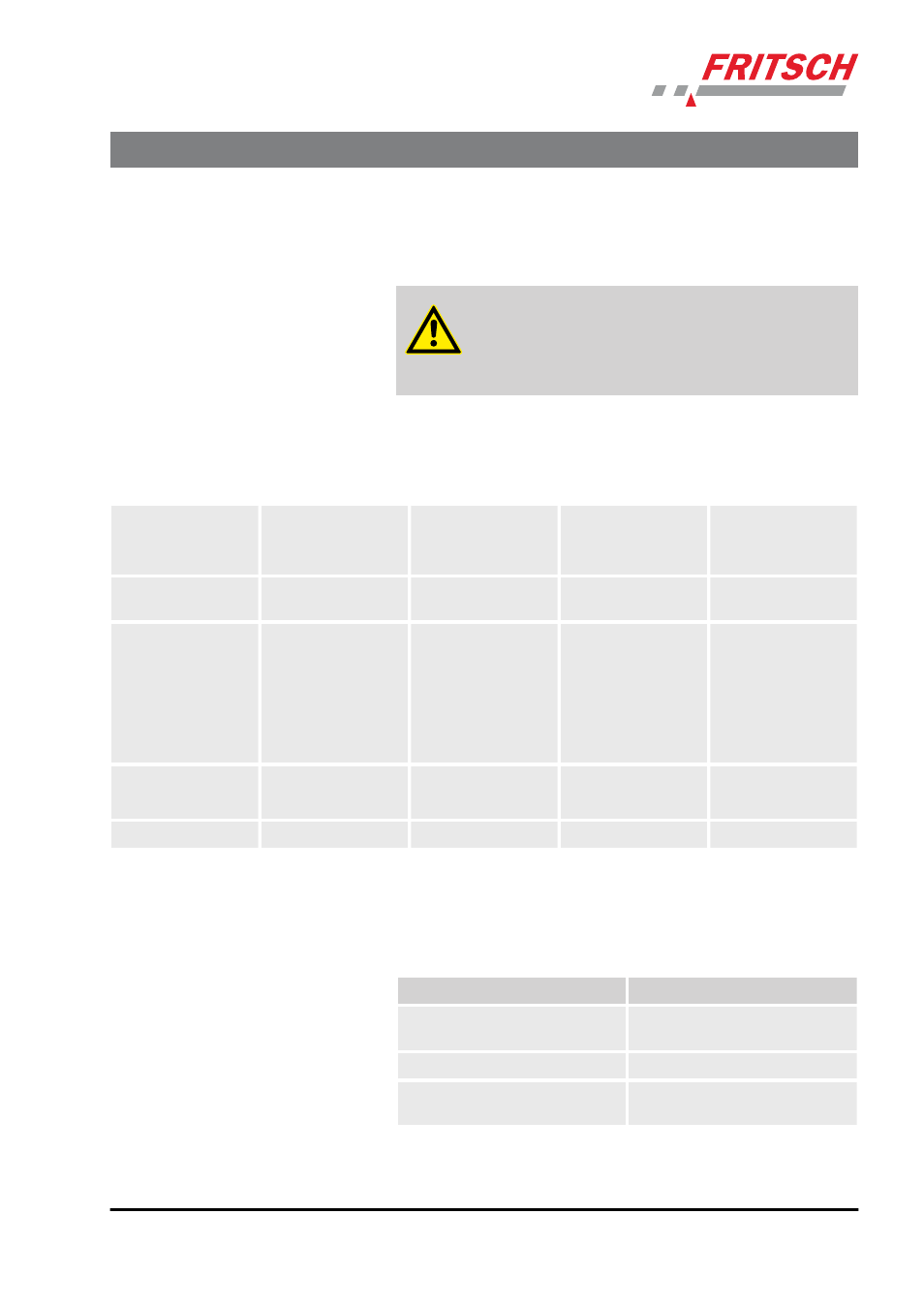

To prevent excessive wear caused by abrasion, the hardness and density

(specific weight) of the grinding bowl and grinding balls used must be

greater than that of the material used.

Material

(bowl and balls)

Main components of

the material

Density in g/cm

3

Abrasion resistance

Use for grinding

stock

Zirconium oxide

(95% ZrO

2

)

5.9

Very good

Fibrous, abrasive

samples

Stainless steel

Bowl:

(17-19% Cr + 8-10%

Ni)

Balls:

(12.5-14.5% Cr + 1%

Ni)

7.8

Fairly good

Medium-hard, brittle

samples

Tempered steel

Bowl: (11-12% Cr)

Balls: (1.0-1.65% Cr)

7.9

Good

Hard, brittle samples

PTFE

2,2

Fairly good

Soft, brittle samples

It is recommended to choose a grinding bowl and grinding balls that are

made of the same material.

6.1.1 Size of the grinding balls

Type of feed material

Ball diameter

Hard samples with a maximum

size of 2-5 mm

15 mm

Fine material (0.5 mm)

10 mm / 5 mm

Homogenisation of dry or liquid

samples

10 mm / 5 mm

Using the planetary mill

- 19 -