3 calculated weight of a ball, Material quantity), Using the planetary mill – FRITSCH PULVERISETTE 23 User Manual

Page 20

These are reference values: The size of bowls and grinding balls may

need to be determined through experimentation.

NOTICE!

It is not advisable to mix balls of different diameters. (If

balls with different diameters are used, increased wear to

the balls is to be expected.)

Fill the grinding bowl with as few balls as possible as the abrasion, wear

and stress on the device and the grinding bowl increases significantly

when filled with more balls. We recommend using a maximum of 3 balls

with a Ø of 10 mm for a 10 ml grinding bowl and a maximum of 6 balls

with a Ø of 10 mm for a 15 ml grinding bowl. No guarantee can be made

if this is exceeded. Balls smaller than Ø 5 mm can also be used to pro-

duce a finer end product. The filling quantity has to be determined

through experimentation.

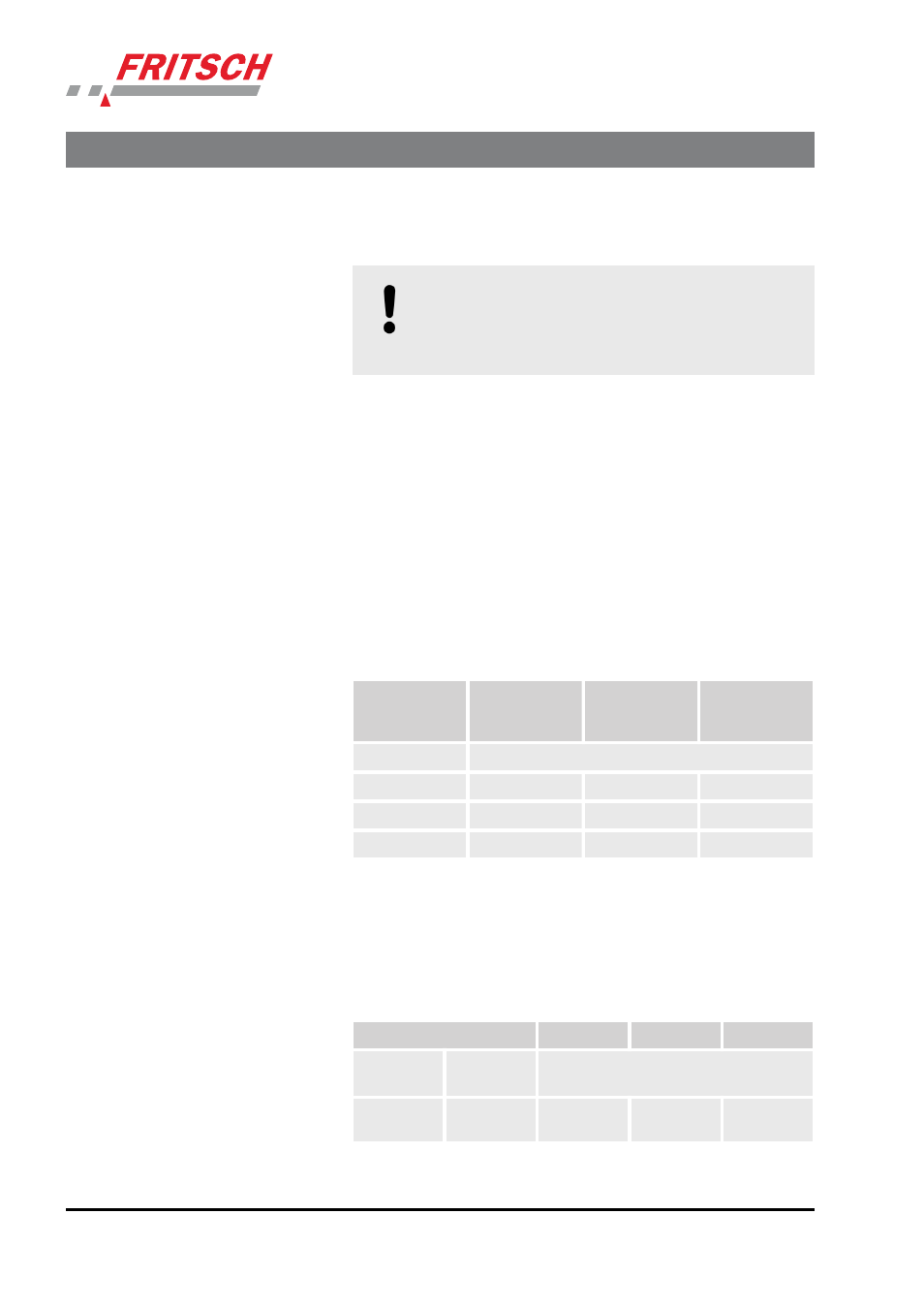

6.1.2 Number of balls per grinding bowl (independent of the material quantity)

A higher number of balls will reduce the grinding duration and the

grinding results will be within a smaller grain size range.

Grinding bowl /

Useful capacity

(grinding stock)

15 ml / 0.5 - 5

ml

10 ml / 0.2 - 1

ml

5 ml / 0.01 - 1

ml

Balls

∅

15 mm

2

1

10 mm

5

3

1

5 mm

60

30

20

The number of balls should be complied with to avoid unnecessary wear.

The lowest number of balls is the minimum filling quantity; the largest

number of balls is the ideal ball filling for the shortest grinding time (e.g.

8 balls with a diameter of 10 mm is ideal for the 15 ml grinding bowl).

6.1.3 Calculated weight of a ball

Ball diameter in mm

5

10

15

Material

Density in g/

cm

3

Calculated weight of a ball in g

Zirconium

oxide

5,9

0,37

2,98

10,07

Using the planetary mill

- 20 -