Pcv testing – Cub Cadet MTD 70 Series User Manual

Page 33

B

ASIC

T

ROUBLESHOOTING

27

PCV testing

The PCV valve is located in the valve cover and allows the crankcase pressure to escape.

Leakage and blockage are the two failure modes for a PCV system. Either mode will cause crankcase pressure

to build-up, though the effects of a blocked PCV are generally more dramatic. Increased case pressure will result in

oil entering the combustion chamber.

1.

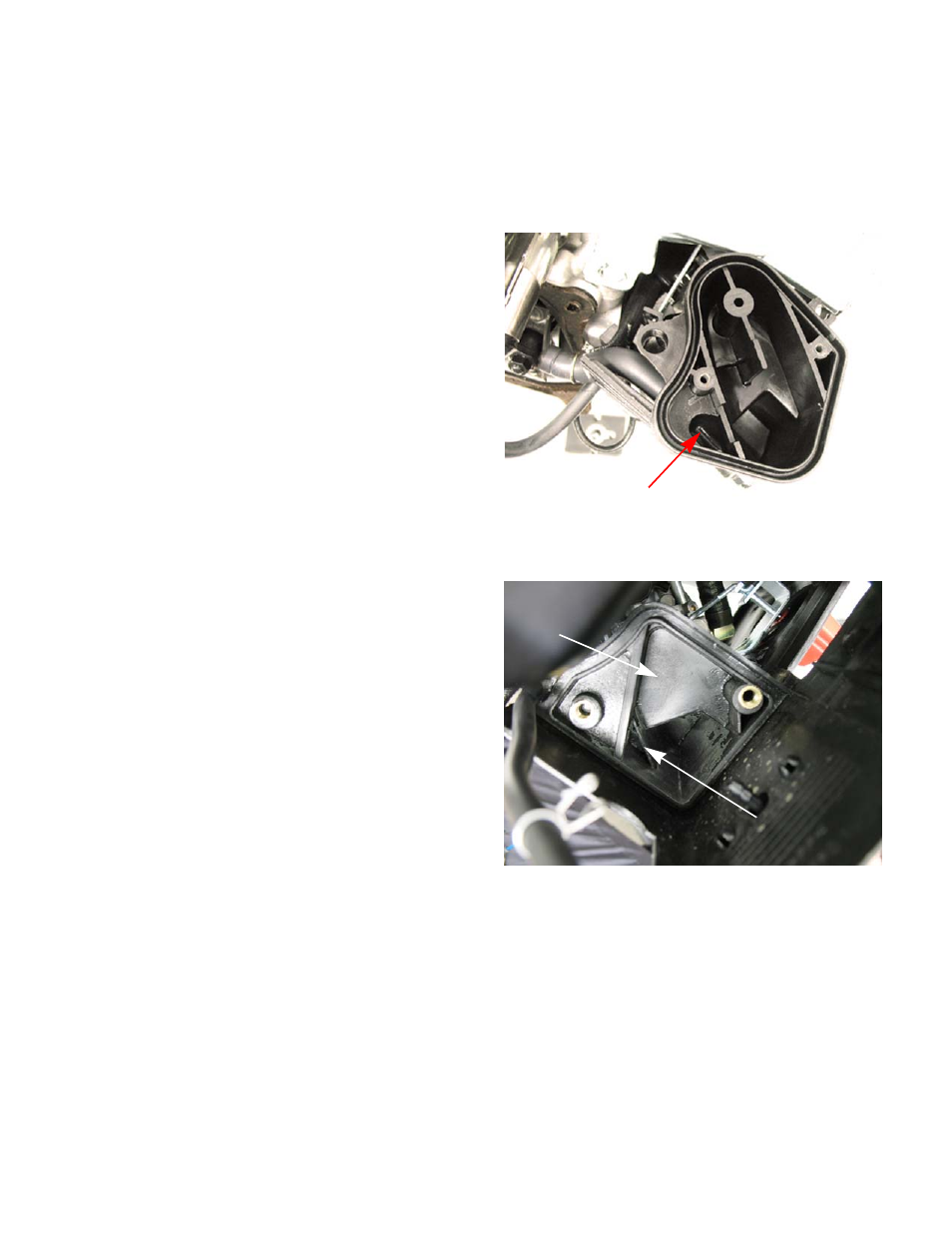

The PCV chamber is vented to the air filter through

a molded rubber hose. The rubber hose directs

crankcase fumes to a chamber within the air filter

housing. See Figure 2.3.

NOTE:

On snow blower engines the breather hose

connects to a chamber inside the lower half

of the heat box assembly. See Figure 2.4.

2.

When functioning properly, the PCV valve (Positive

Crankcase Ventilation) works with the inherent

pumping action of the piston in the bore to expel

pressure from the crankcase.

NOTE:

Normally, small engines run with slightly

negative case pressure. This case pressure

can be measured using a slack-tube water

manometer, or an electronic version of the

same tool. Less than (between -3 and -4”) (

-7.6 - 10.2cm) of water is a typical reading at

idle.

3.

An engine that fails to purge extra case pressure in

a controlled manner will build case pressure. The

pressure will find it’s own way out of the engine in

undesirable ways.

•

Oil will be forced by the rings and valve guides, being burnt in the combustion chamber.

•

The cause of this oil burning can be mistaken for a worn-out engine, if proper diagnosis (compression,

leak-down, and case pressure) is not performed.

4.

Experimentation by MTD’s Training and Education Department has revealed the following characteristics of

MTD engines:

•

A leaky PCV system will not build-up substantial case pressure.

•

A leaky PCV system will allow the engine to ingest contaminants through the system, accelerating engine

wear.

•

A blocked PCV system will allow crankcase pressure to build very rapidly. Noticeable oil fumes will be evi-

dent in the exhaust within several minutes of normal operation.

Figure 2.3

crankcase air chamber

Figure 2.4

Bottom of heat box

crankcase air chamber