Crank shaft inspection – Cub Cadet MTD 70 Series User Manual

Page 112

61/65/70/75 Series Horizontal Shaft Engines

106

Crank shaft inspection

1.

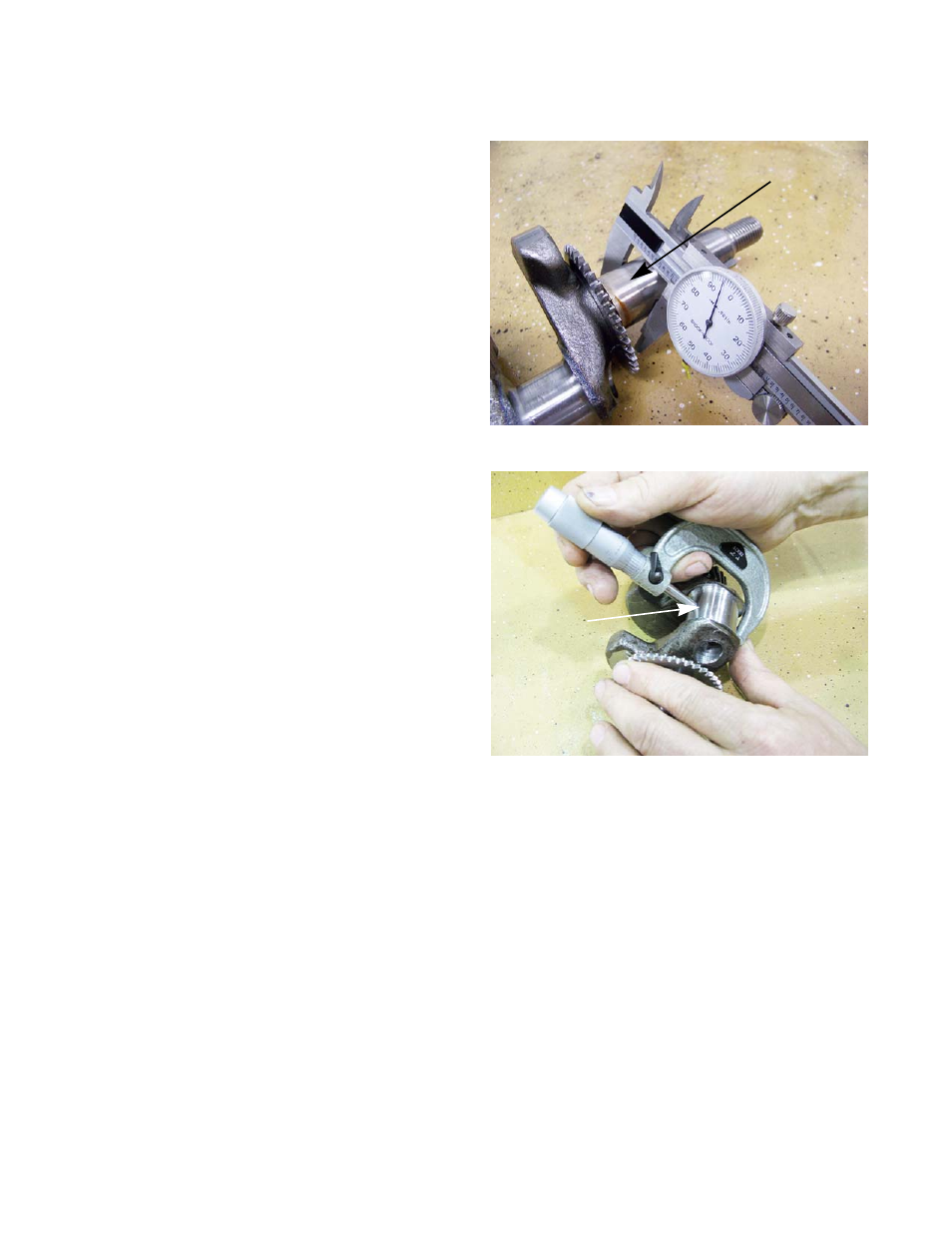

Inspect the crank shaft journals for galling, scoring,

pitting or any other form of damage.

2.

Measure the journals at the bearing contact points

using a vernier caliper or a micrometer. See Figure

10.7.

NOTE:

Micrometers are the preferred and most

accurate way to measure the journals.

3.

Inspect the crank pin for galling, scoring, pitting or

any other form of damage.

NOTE:

This is mostly a visual check. Measurement

is to determine if it is within the specifications

after it is found to be OK visually.

4.

Measure the crank pin using a vernier caliper or a

micrometer. See Figure 10.8.

5.

Check the crank shaft for straightness by measuring

the run out. The crank shaft run out can be check

by:

5a. Place the crank shaft on a pair of matched V-

blocks or in the engine block with the sump

installed.

5b. Place a dial indicator at a smooth point at either

end of the crank shaft.

5c. Slowly turn the crank shaft while watching the

dial indicator.

NOTE:

Stop the crank shaft before the dial indicator

hits the keyway.

5d. Compare the reading on the dial indicator to the specification listed at the end of this chapter.

5e. Repeat the above steps on the other end of the crank shaft.

Figure 10.7

Bearing contact

area

Figure 10.8

Crankpin