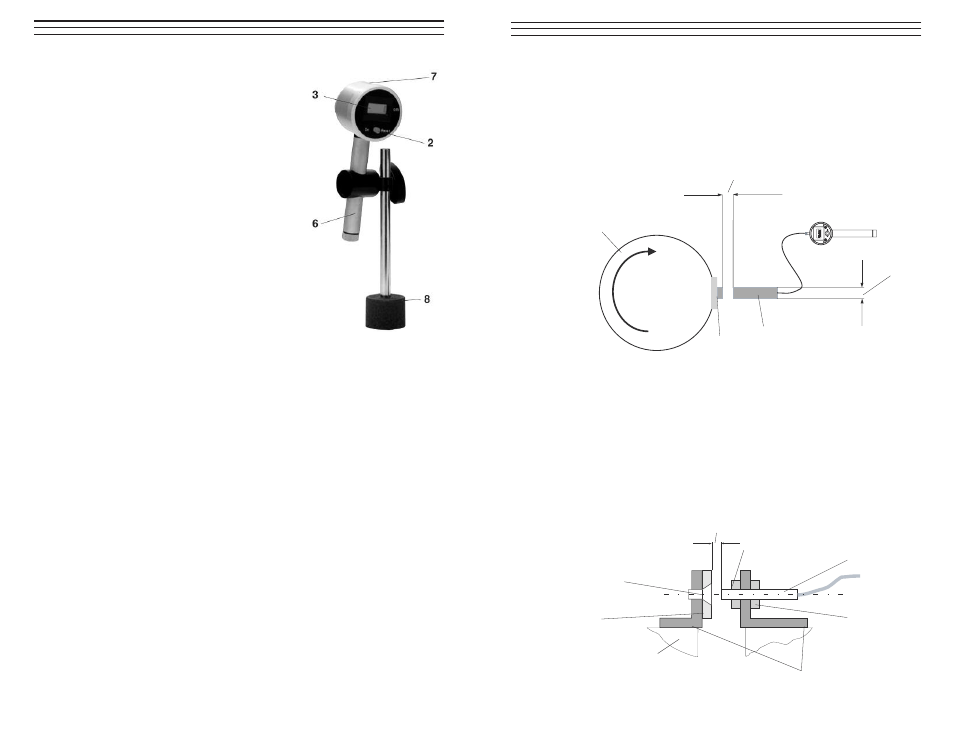

Fig. 3 fig. 4 – Checkline LMI-LMC User Manual

Page 6

6

3.2 Setup

1. Place the magnetic base (8) at the desired

measuring point.

2. Insert the handle ( 6) of the electronic

yarn consumption meter in the holder of

the magnetic base.

3. Insert the material to be measured in the

groove of the filament guide ring (7) on

the rear side of the instrument. The

filament guide ring can be turned by

360°.

4. Adjust the electronic yarn consumption

meter in such a way that the angle of

material contact with the measuring

wheel is 120° minimum (see Fig. 2)

to eliminate material slip.

NOTE: The angle of material contact with the

measuring wheel must be at least 120°.

3.3 Measuring Procedure (refer to diagram on page 4)

1. On the LMC-S and LMC-I models, set the preselect switches

(9) and (10) to position 0, as shown in Fig. 4 on page 8.

2. Press the ON / RESET switch (2) to switch on the electronic

yarn consumption meter.

3. Switch on the knitting machine for the desired number of machine cycles.

The instrument now continuously measures the yarn consumption.

4. Switch off the knitting machine.

5. The display (3) now shows the measured length of yarn.

If a new yarn consumption measurement is necessary, repeat the

compete Measuring Procedure

NOTE: The electronic yarn consumption meter powers off automatically when the

measuring wheel on the rear of the instrument has not been moving for about

two minutes. The measured values are deleted.

7

4.0 M

EASURING

W

ITH

T

HE

LMC-S A

ND

LMI-S M

ODELS

4.1 Measuring with Manual Start /Stop

Follow the procedures outlined in section 3.0.

4.2 Measuring with Automatic Start/Stop Signal

The LMC-S and LMI-S models feature an adjustable counter for up to 99

cylinder revolutions of the knitting machine. The cylinder revolutions are

monitored by a magnetic switch.

To use this feature, the supplied magnet (12) must be mounted to the cylinder of

the knitting machine by using an M5 flat head bolt. The supplied magnetic

switch (11) is fitted to the stationary part of the knitting machine so that it is at

the same height as the magnet (12) (see Fig. 4 below). The switching distance

between the magnet and magnetic switch should be set to about 2mm with the

adjusting nut and lock nut of the magnetic switch.

Recommended switching distance approx. 2 mm

M5 thread

11 Magnetic switch

12 Magnet

Cylinder of circular

knitting machine

M5 flat head bolt

R

Recommended switching distance approx. 2 mm

Cylinder

Magnet

Magnetic switch

Adjusting nut

Lock nut

Mounting angle

Mounting Example

Fig. 3

Fig. 4