Checkline DIS-RL User Manual

Page 4

page 9

TORQUE MEASUREMENT

page 4

TORQUE MEASUREMENT

Output is available in PD, PP and C modes. In PD and PP modes peak

data is output when ZERO is pressed or activated by the AUTO ZERO

function. In C mode, the gauge outputs data continuously 180

data/second.

GENERAL OPERATION

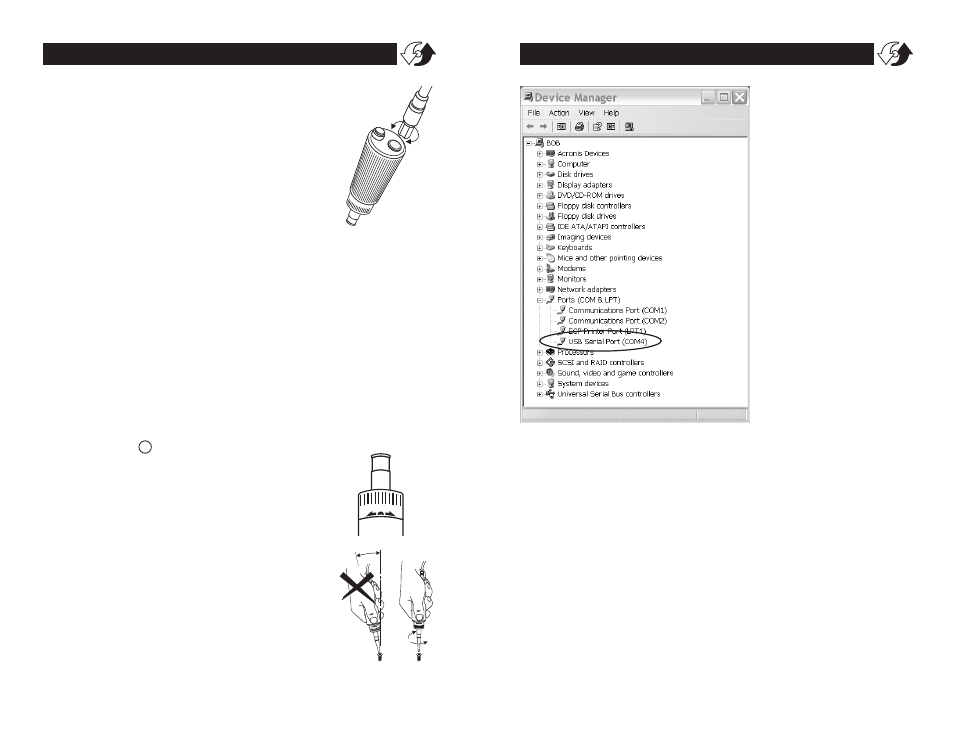

1. Connect the torque sensor to the tester display

unit with cable provided. When connecting

the cable to the torque sensor, rotate the round

connector to find the matching groove, then

push in until it makes positive connection

(When disconnecting the cable from the

torque sensor, hold the silver metal part of the

round connector and pull out).

2. To select the desired measuring unit (lbf-in, kgf-cm, N-m, N-cm),

press POWER, then hold UNITS for 4 four seconds until a beep

sounds. Press UNITS to cycle choices. Press PRG/SET to enter.

3. Press and hold MODE for one second to select from the follow-

ing Measuring Modes.

Real Time–Displays torque transients (no output or indicator)

PP Mode– Peak, captures peak torque (peak data output, PP

appears on display)

PD Mode– First Peak, capture first peak value (peak data

output, PD appears on display)

C Mode–

Continuous RS-232 output Display and output

torque transients (180 data/sec., GOOD indicator

flashes)

4. Insert Phillips tip into the screwdriver sensor.

5. Select ratchet operation by turning the ratchet

one click clockwise or counter-clockwise from

the center position. To disable ratcheting, turn

the ratchet so the semi circle is in the center

position.

6. Press the CLEAR button on the display unit or

the button on the screwdriver to zero the dis-

play. Insert the screwdriver tip into the screw,

hold perpendicularly (not at an angle), and

turn to measure.

7. After measuring, press CLEAR on the display

unit or the button on top of the screwdriver

sensor to zero the display for the next test.

6