Checkline DID-4 User Manual

Page 4

page 9

TORQUE MEASUREMENT

page 4

TORQUE MEASUREMENT

Output is available in PD, PP and C modes. In PD and PP modes peak

data is output when ZERO is pressed or activated by the AUTO ZERO

function. In C mode, the gauge outputs data continuously 160

data/second.

Comport signal

8 data, 2 stop, no parity. Baud Rate: 19,200 bps.

Output Connector

USB A/B cable

Peak Data Output Format

[CAN] _ _ _ [SO] [value] _ [SI] [unit] [CR]

(_ _ _ is memory location)

[CAN]:

ASCII control code 24

_:

Space (code 32)

[SO]:

ASCII control code 14

[value]:

Output data with sign and decimal point. Plus sign

represents for CW torque and minus sign for CCW.

[Value] always occupy six locations and empty

locations will be filled with spaces.

[SI]:

ASCII control code 15

[unit]:

N*m _ _ _=N.m

kgf*cm = kg.cm

lb*in _ = lb.in

[CR]:

ASCII control code 13 (Carriage Return)

Continuous Output Data Format

[CAN] [value] [CR]

GENERAL OPERATION

1. Press and hold MODE for one second to select from the follow-

ing Measuring Modes.

Real Time–Displays torque transients (no output or indicator)

PP Mode– Peak, captures peak torque (peak data output, PP

appears on the display)

PD Mode– First Peak, capture first peak value (peak data

output, PD appears on the display)

C Mode–

Continuous RS-232 output Display and output

torque transients (180 data/sec., C appears on

the display)

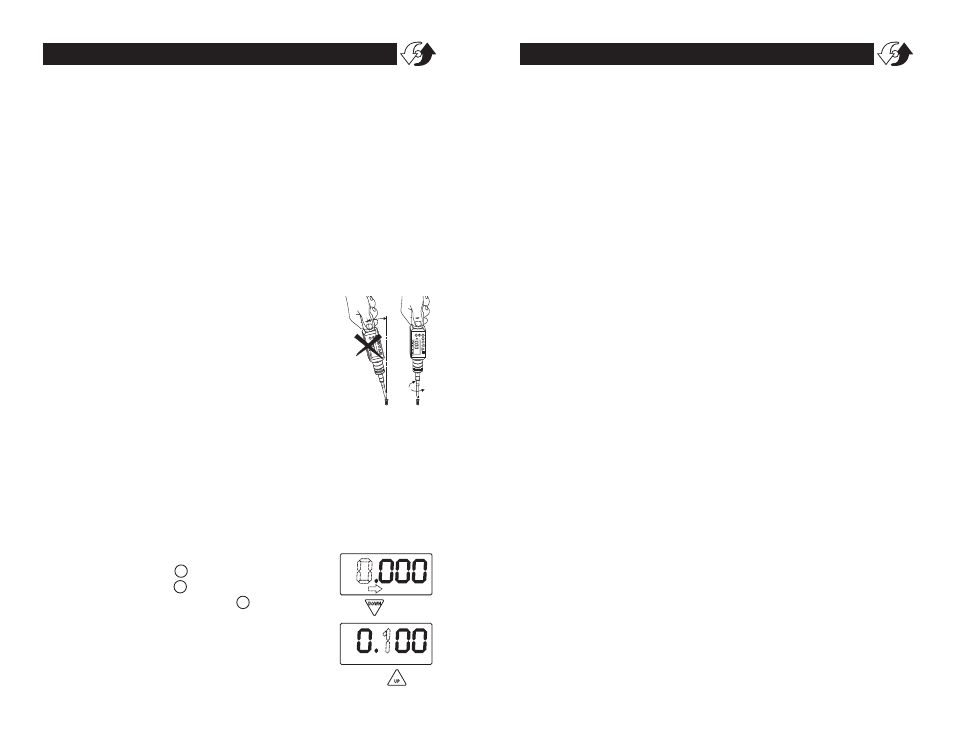

2. Insert Phillips tip into the screwdriver.

3. To select ratchet operation turn the ratchet one

click clockwise or counter-clockwise from the

center position. To disable ratcheting, turn it so

the semi circle is in the center position.

4. Press the CLEAR button on the display unit to

zero the display. Insert the screwdriver tip into

the screw, hold perpendicularly (not at an

angle), and turn to measure.

5. After measuring, press CLEAR to zero the display for the next test.

PROGRAMMING

Press POWER to turn on. Press PRG for one second. The display

shows, "HI" and then the High setpoint value. This confirms the

tester is ready for the following programming steps.

1.

High Setpoint (HI)

After "HI" is displayed and the High setpoint

value, press DOWN

to move the numeric

place and press UP

to select values i.e. 50.0

for 50.0 lbf-in, then press PRG

to enter.

2.

Low Setpoint (LO)

After High value is entered, "LO" is displayed,

then the Low setpoint value. Press DOWN to

move the numeric place and press the UP to

select values, then press PRG to enter.

8

7

6