Checkline ODT User Manual

Page 3

3

3.0 O

PERATING

P

ROCEDURE

3.1 Inserting the material to be measured

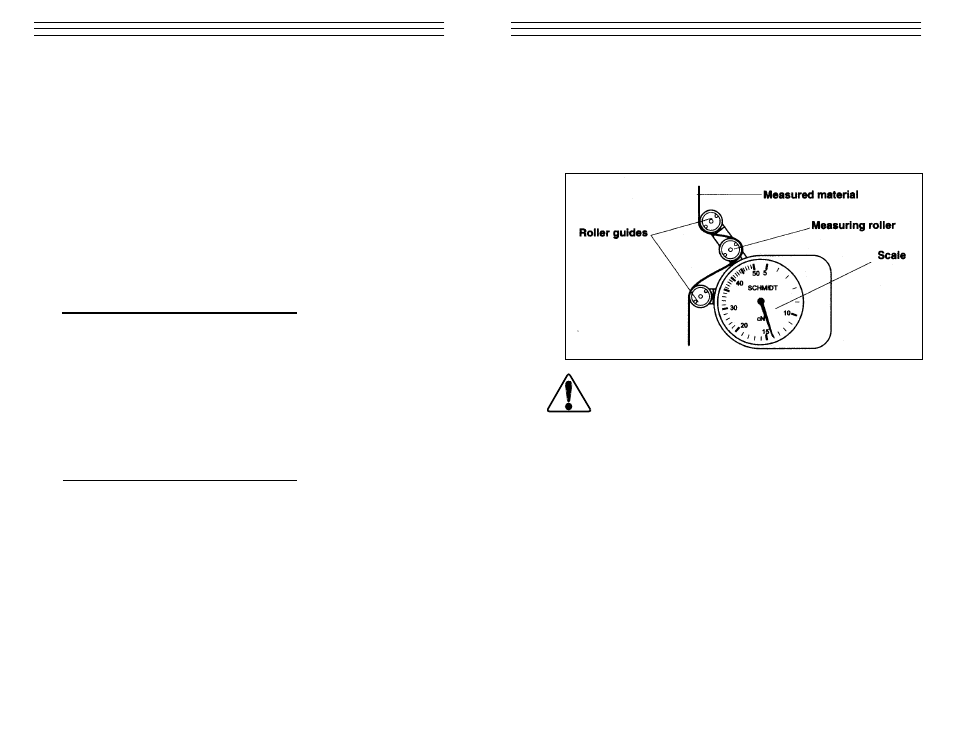

Carefully thread the material to be measured through the measuring roller

and roller guides, as shown below. It is important to ensure that the measured

material runs smoothly through the roller.

WARNING

To avoid damage do not move the center roller by hand

using force.

3.2 Setting the Maximum Tension Detector (optional)

Need copy?

Are there any other steps that need to be taken

before the gauge begins operating?

6

6.0 S

PECIFICATIONS

Calibration

According to factory procedure

Accuracy

± 1% full scale (FS) or ± 1 graduation on scale

Scale diameter

2.28 in (58mm)

Temperature range

50 to 113 °F (10 to 45 °C)

Air humidity

85% RH, max.

Housing material

Chill-cast aluminum

Housing dimensions

3.1 in x 2.45 in x 1.1 in (78 x 62 x 27 mm) — L x W x H

Weight

approx. 0.7 lbs. (300g)

7.0 T

ENSION

R

ANGES

/C

ALIBRATION

M

ATERIAL

Model

Range (grams) Calibration Material*

ODT-10 2-10

Faden:

25 tex

ODT-20 2-20

Faden: 25

tex

ODT-30 3-30

Faden: 25

tex

ODT-50

5-50

PA 0.12mm Ø

ODT-70

10-70

PA 0.12mm Ø

ODT-100

10-100

PA 0.12mm Ø

ODT-200

20-200

PA 0.20mm Ø

ODT-300

20-300

PA 0.20mm Ø

ODT-400

40-400

PA 0.20mm Ø

ODT-500

50-500

PA 0.20mm Ø

ODT-800

20-800

PA 0.20mm Ø

ODT-1K

50-1000 grams PA 0.30mm Ø

* Suitable for 95% of applications. PA = Polyamide Monofilament. If the material

to be measured differs significantly from the factory calibration material in diameter,

rigidity, shape, etc., we recommend calibration using customer material. For this

purpose, a material sample of about 5 m should be supplied. International unit for

tension force: 1 cN = 1.02 g = 0.01 N