Checkline MKM User Manual

Page 4

-4-

3.0

O

PERATING

P

ROCEDURE

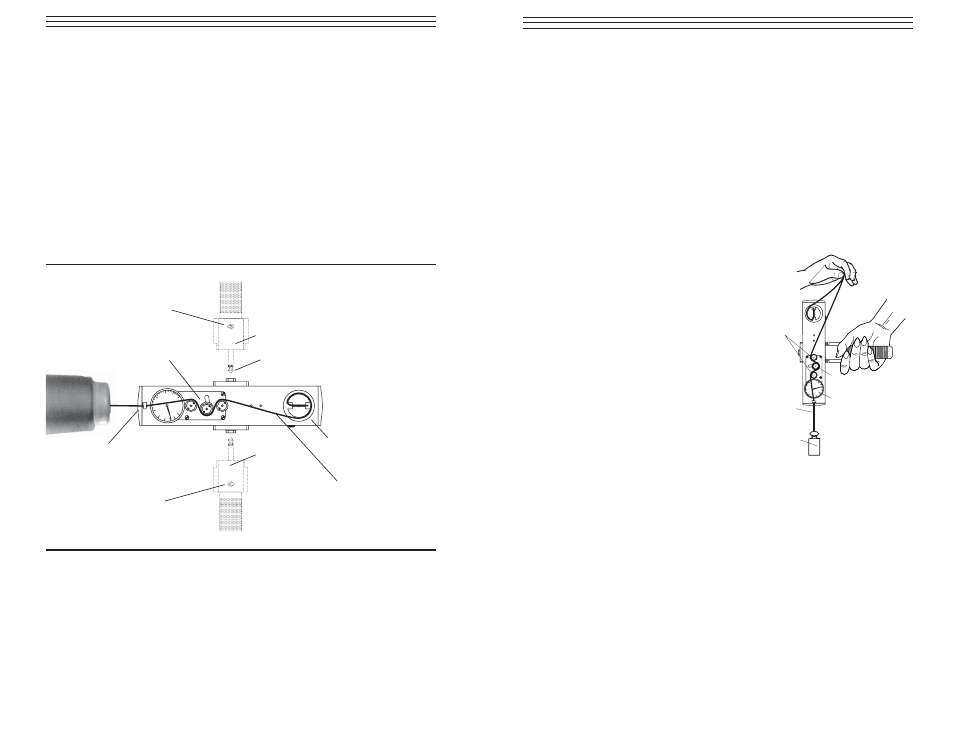

NOTE: To facilitate easy use, the MKM handle can be attached to the top or

bottom of the gauge body (see diagram on page 2).

1. Depending on the orientation of use, plug in the jack plug of the handle at

either of the two jack sockets provided on the sides of the tension meter.

2. Thread the process material through the guide eye, the outer rollers

and the measuring roller. Then wind the process material around the

take-up wheel two or three times.

3. Press the motor switch to start measuring. The scale now shows the measured

tension values. If the scale does not show a reading, the process material may

be threaded throug the rollers incorrectly. Not the proper position of the

process material in the diagram below and retry.

Eye guide

Take up wheel

Motor switch

Handle

Handle

Process material

Measuring roller

Motor switch

Jack plug

-5-

4.0

V

ERIFYING THE

MK C

ALIBRATION

All tension meters are calibrated with standard materials—such as polyamide

monofilament (PA)— according the factory procedure. Filament sizes are noted

in Section 5.2.

NOTE: Any difference in process material size and rigidity from the standard

material may cause a deviation of the accuracy.

In 95% of all industrial applications the factory calibration has been proven to

provide the best results and is used for comparative purposes.

If the process material differs significant in size, rigidity and shape we recom-

mend special calibration using customer`s sample. For this purpose a material

sample of 5 meters in length should be supplied.

1. Suspend a known weight that

corresponds to the tension to be

measured (pay attention to the

correct unit of measure) from

the process material, vertically,

as shown in the figure. Always

use a fresh portion of the

material to be measured.

2. Before the final check, move

the process material slowly up

and down to compensate any

friction caused by the instrument

and thus ensure the repeatability.

3. The tension value should be

equal to the value of the

suspended weight.

If this procedure shows a deviation beyond the allowable tolerance and

reliable operation is no longer possible, the instrument must be returned to

the factory for recalibration or repair.

WEIGHT

OUTER

ROLLERS

MEASURING ROLLER

PROCESS

MATERIAL

SCALE