Checkline HPSA-R User Manual

Page 4

-4-

3.0 V

ERIFYING

F

UNCTIONALITY

The HPSA-R Durometer is calibrated against industry standards as specified

in ASTM, DIN and JIS Test Procedures. Calibrated Test Samples CAN NOT

BE USED for verification of the calibration, as these test samples are subject

to change due to temperature, sunlight and other ambient conditions.

Certification of the calibration is normally done at test facilities that can

independent test the internal spring forces of the Durometer and check the

travel/reading accuracy of the dial indicator.

You can, however, test that the gauge is functional and undamaged using the

optional Zero Test Block which can be ordered under item numbers

HP-TB-R20, HP-TB-R35, HP-TB-R55.

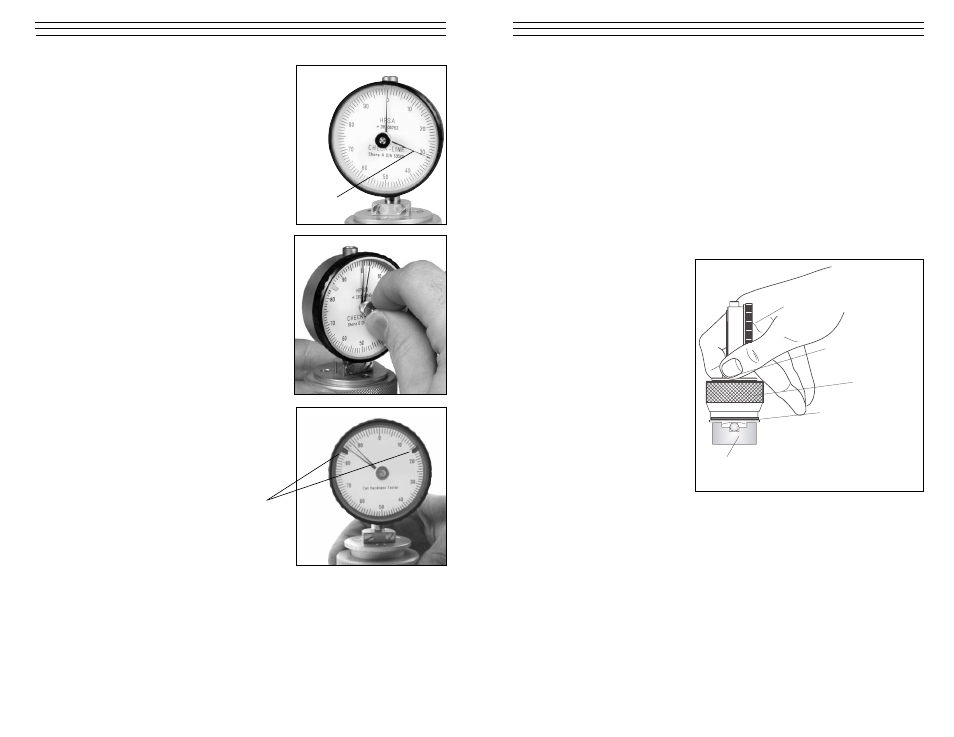

1. Press the Durometer

down on the test block.

Do not move the spring-

loaded outer ring.

2. The scale pointer should

make one full turn on the

scale, from zero to zero,

when you press down on

the instrument. If it does

not, contact Electromatic

for assistance.

NOTE:

Do not loosen the holding screws of the movement under any

circumstances. Loosening these screws may alter the calibration of the

instrument.

-5-

Scale

Spring-loaded

outer ring

Color marking

Holding screws

Test block

Part #’s: HP-TB-R20, HP-TB-R35, HP-TB-R55

Fig. 1

2.1 Memory

Pointer

The Memory Pointer moves with the

measurement pointer when a measure-

ment is taken. However, when pressure

on the outer shell is released, and the

measurement pointer returns to zero, the

Memory Pointer remains in position,

marking the last measurement.

To return the Memory Pointer to the

zero position prior to taking another

measurement, rotate the knurled knob

on the face of the instument counter-

clockwise until the pointer has been

reset. See figure at right.

2.2 Upper and Lower Limit Markers

Two movable markers can be rotated

around the faceplate to mark the upper

and lower measurement limits.

Memory

Pointer

Upper and Lower Limit Markers