Checkline AD-100 User Manual

Page 4

– 3 –

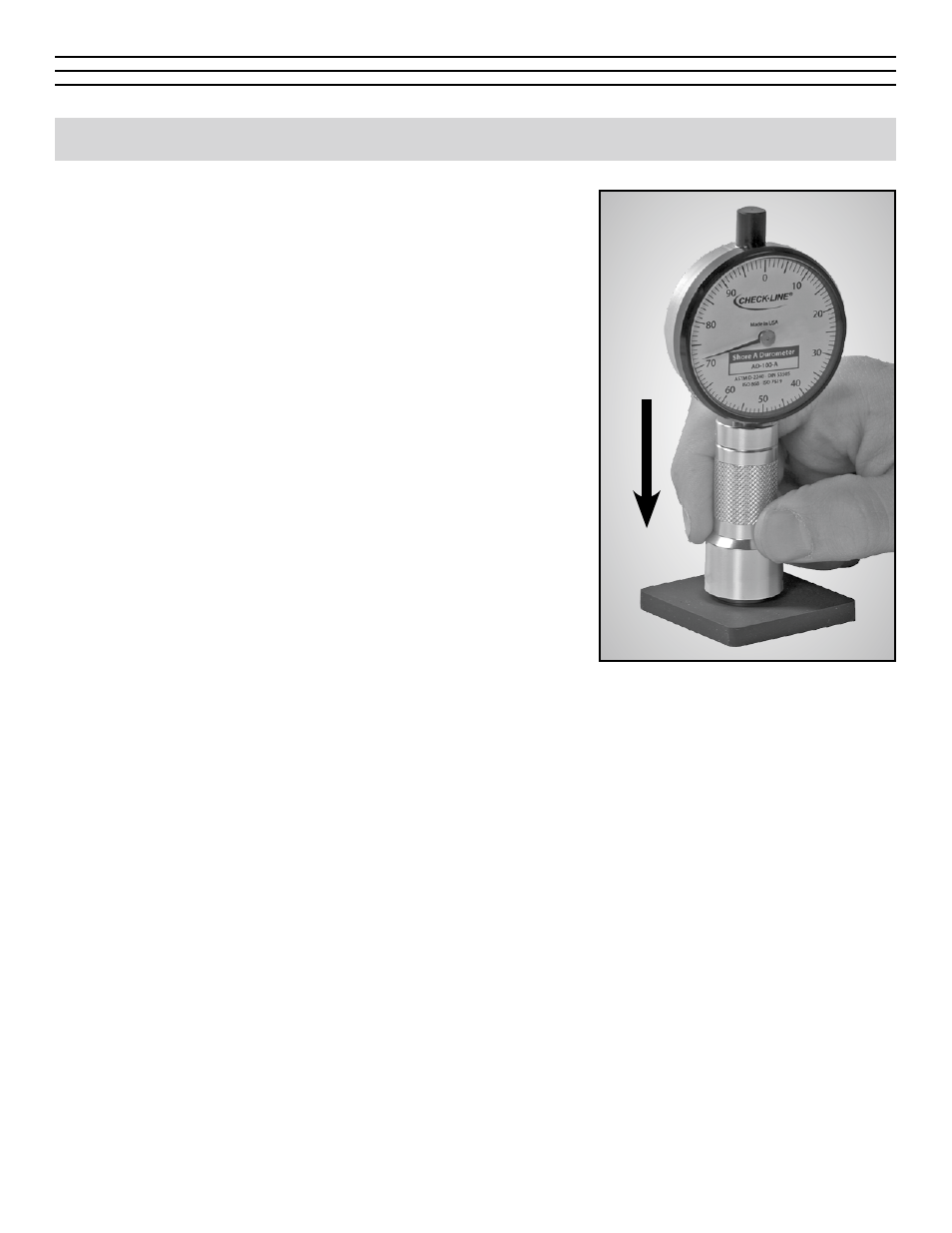

2.0 Testing Procedure

1. Place the instrument on the material

to be tested. The AD-100 can be used at

any angle, it does not need to be vertical.

NOTE:

If the gauge is equipped with the

Memory Pointer option make sure the

pointer is returned to zero before starting.

2. Press the foot of the gauge firmly

against the specimen, but not so

firmly as to imbed the foot into the

surface of the material.

3. Maintain pressure for 2 to 3 seconds.

The dial hand gives the reading in

durometer points.

ImPOrTaNT:

After the initial reading has

been noted, continue maintaining pressure

for several more seconds. Creep or cold-flow of the specimen, if present,

will be evident by receding action of the dial hand.

4. Repeat above steps for each use.

An example of a properly noted durometer reading:

“Durometer A 61, Creep 7 at 15 seconds, 73°F.”

- CDT-1000HD (6 pages)

- CDT-2000HD (9 pages)

- DT-105A (7 pages)

- DT-205LR (7 pages)

- PLT-5000 (7 pages)

- HTM (10 pages)

- YSL-2000HD (9 pages)

- DLM-107A (2 pages)

- A2105 (4 pages)

- DT-5TG (8 pages)

- MT2013 (2 pages)

- DT-209X (68 pages)

- WT3-200 (29 pages)

- WTT-110 (11 pages)

- WTT-110 (2 pages)

- WTTM-GEN1 (11 pages)

- TT-QC (10 pages)

- TT-QCM (16 pages)

- MTM (14 pages)

- ILTT (9 pages)

- TT02 (28 pages)

- TT Series (6 pages)

- DI-1M (6 pages)

- DIS-IP (6 pages)

- R55 (18 pages)

- TT05 (26 pages)

- CAP-TNP (10 pages)

- TSTM (9 pages)

- ETW (11 pages)

- HTG2 (8 pages)

- DD-100 (3 pages)

- HP Series (6 pages)

- HPSA-R (5 pages)

- EMS4 (27 pages)

- MKM (5 pages)

- MST (24 pages)

- MLT (18 pages)

- DT-5TS (20 pages)

- DIW (6 pages)

- DID-4 (6 pages)

- DIS-RL (6 pages)

- DSD-4 (4 pages)

- MGT (2 pages)

- CAP-TT01 (28 pages)