Checkline PaintCheck User Manual

Page 2

- 2 -

1.0 I

NTRODUCTION

PaintCheck is a Paint Thickness Gauge especially suited for car

bodies. It non-destructively measures coatings, e.g. lacquer, paint,

plastic, rubber, enamel etc., on iron/steel and on non-ferrous metals

such as aluminium.

PaintCheck automatically recognizes the base material (iron/steel

or non-ferrous metal) and then displays the correct coating thickness.

In addition, with “Ferr” or “Non-Ferr,”,the display indicates whether

measurement was made on iron/steel or on non-ferrous metal.

2.0 P

OWER

K

EY

- O

N

/ O

FF

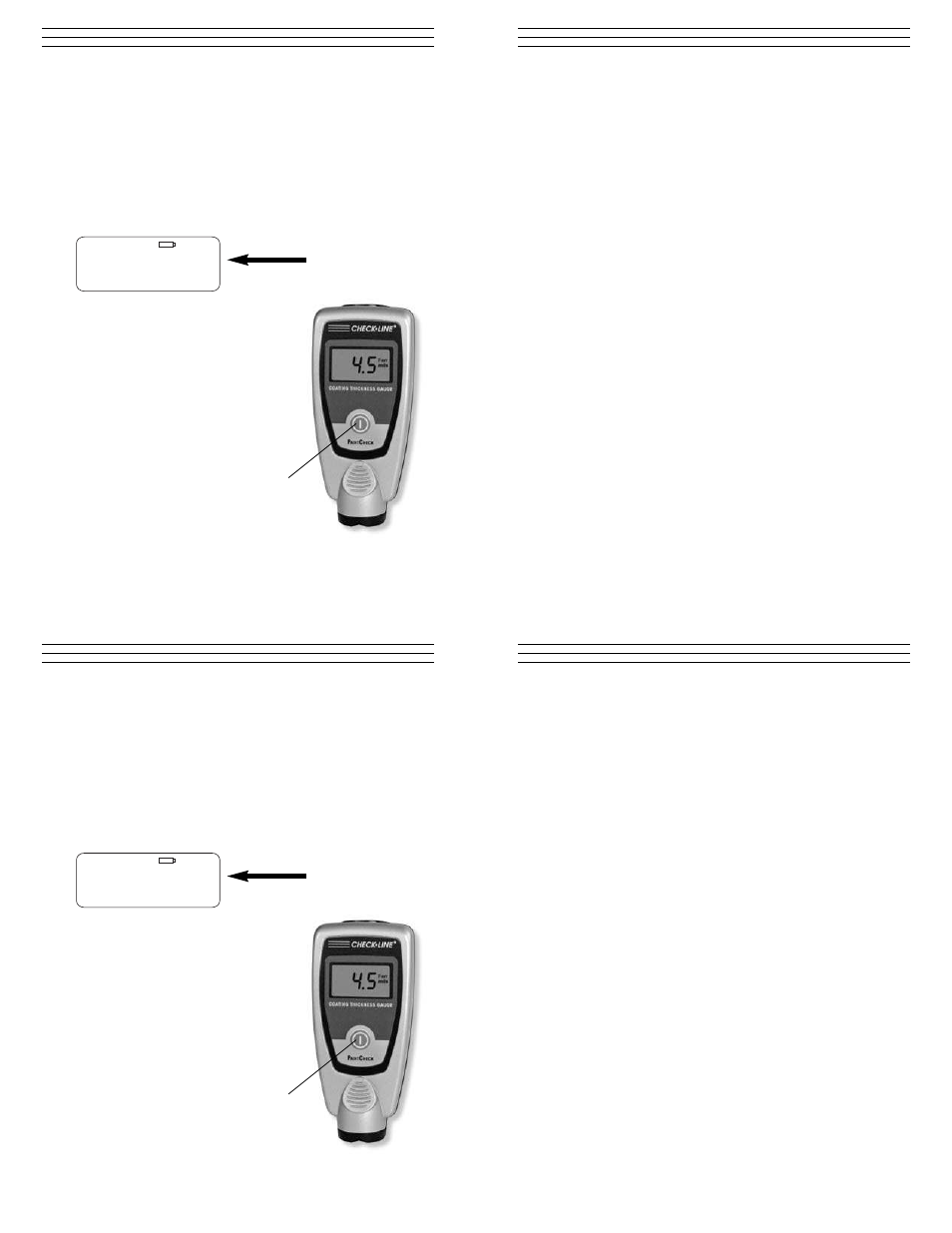

Switching On: Press the Power Key

briefly.

Switching Off: Press AND HOLD

the Power Key for about 2 seconds.

Auto Off: 1.5 min after the last

measurement.

8.8.8.8

mils

µmm

AUTO FN

Non-

Ferr

Power Key

- 7 -

8.0 T

ECHNICAL

D

ATA

Measuring range

0" – 0.08" (0 – 2mm)

Tolerance

±5 µm (+5% of readings)

Resolution

0 – 500 µm

1

5 µm

500 µm – 1,000 µm

10 µm

1,000 µm – 2.000 µm

25 µm

Display/height of digits

4-digits / 0.39" (10mm)

Minimum measuring area

1.57" x 1.57" (40mm x 40mm)

Minimum curvature radius

convex 1.97"

(25mm)

concave .98"

(50mm)

Minimum substrate thickness

iron/steel

2.95" (0.75mm)

non-ferrous metal

.98" (0.25mm)

Calibration

not necessary

Temperature range

32 – 122 °F (0 – 50 °C)

Surface temperature

of specimen

59 – 140 °F (15 – 60 °C)

Power supply

2 x Micro (AAA) 1.5V

Dimensions

4.3" x 1.97" x .98"

(110 x 50 x 25mm)

Weight incl. batteries

0.2 lbs. (90 g)

Protection class

IP52 protection against dust

and dripping water

- 2 -

1.0 I

NTRODUCTION

PaintCheck is a Paint Thickness Gauge especially suited for car

bodies. It non-destructively measures coatings, e.g. lacquer, paint,

plastic, rubber, enamel etc., on iron/steel and on non-ferrous metals

such as aluminium.

PaintCheck automatically recognizes the base material (iron/steel

or non-ferrous metal) and then displays the correct coating thickness.

In addition, with “Ferr” or “Non-Ferr,”,the display indicates whether

measurement was made on iron/steel or on non-ferrous metal.

2.0 P

OWER

K

EY

- O

N

/ O

FF

Switching On: Press the Power Key

briefly.

Switching Off: Press AND HOLD

the Power Key for about 2 seconds.

Auto Off: 1.5 min after the last

measurement.

8.8.8.8

mils

µmm

AUTO FN

Non-

Ferr

Power Key

- 7 -

8.0 T

ECHNICAL

D

ATA

Measuring range

0" – 0.08" (0 – 2mm)

Tolerance

±5 µm (+5% of readings)

Resolution

0 – 500 µm

1

5 µm

500 µm – 1,000 µm

10 µm

1,000 µm – 2.000 µm

25 µm

Display/height of digits

4-digits / 0.39" (10mm)

Minimum measuring area

1.57" x 1.57" (40mm x 40mm)

Minimum curvature radius

convex 1.97"

(25mm)

concave .98"

(50mm)

Minimum substrate thickness

iron/steel

2.95" (0.75mm)

non-ferrous metal

.98" (0.25mm)

Calibration

not necessary

Temperature range

32 – 122 °F (0 – 50 °C)

Surface temperature

of specimen

59 – 140 °F (15 – 60 °C)

Power supply

2 x Micro (AAA) 1.5V

Dimensions

4.3" x 1.97" x .98"

(110 x 50 x 25mm)

Weight incl. batteries

0.2 lbs. (90 g)

Protection class

IP52 protection against dust

and dripping water