Brookfield UL Adapter User Manual

Page 3

Brookfield Engineering Laboratories Inc.

- 3 -

Operating Instructions M/91-080-I1003

Fluid

Recommended

Recommended

Note

Temperature

Fluid

Tubing

-10

°

C to 15

°

C 50/50

Ethylene

Fluran

R, 2

Do Not Use Gum

Glycol/Water

1

Rubber Tubing With

This Fluid

15

°

C to 65

°

C Water

Gum

Rubber

or Fluran

R

65

°

C to 100

°

C Silicone

Oil

3

Fluran

R

Do Not Use Gum

Rubber Tubing With

This Fluid

R

Fluran is a Registered Trademark of Norton Co.

1. Use only laboratory grade ethylene glycol. Do not use automobile anti-

freeze which contains materials that can damage the equipment.

2. Fluran tubing (5/16" ID) and clamps are offered in a kit, part # ULA-45A.

3. Do not use high viscosity oil. Recommended is 50 centipoise.

6. Add the sample to the chamber. Immerse the spindle into the chamber with the extension link and coupling

nut attached, then thread the water jacket to the locating channel assembly. Once that is done, thread the

coupling nut to the viscometer. This way the spindle is not hanging from the viscometer and it prevents

a mess with the sample. You can hook the extension link to the lip of the chamber to prevent the spindle

from dropping too far down.

7. Level the viscometer. General operating procedures for making viscosity measurements are described in

the viscometer operating instruction manual.

8. UL Adapter spindle factors are shown on page 4. The factor is used to calculate viscosity when using Dial

Reading or Model DV-I Viscometers. Model DV-I+/II/II+ Viscometers and DV-III/DV-III+ Rheometers

calculate the viscosity value automatically when the “cP display mode” is selected. The spindle entry

code for the UL Adapter is 00.

Notes

•

Maximum recommended viscosity for measurement with the UL Adapter is 2000 cP (mPa•s). If viscosity

exceeds 2000 cP, the material being measured may be too viscous to immerse the spindle/tube, and damage

to internal parts of the viscometer may result.

•

For tubing and fluid recommendations when using a Constant Temperature Bath, refer to the table below:

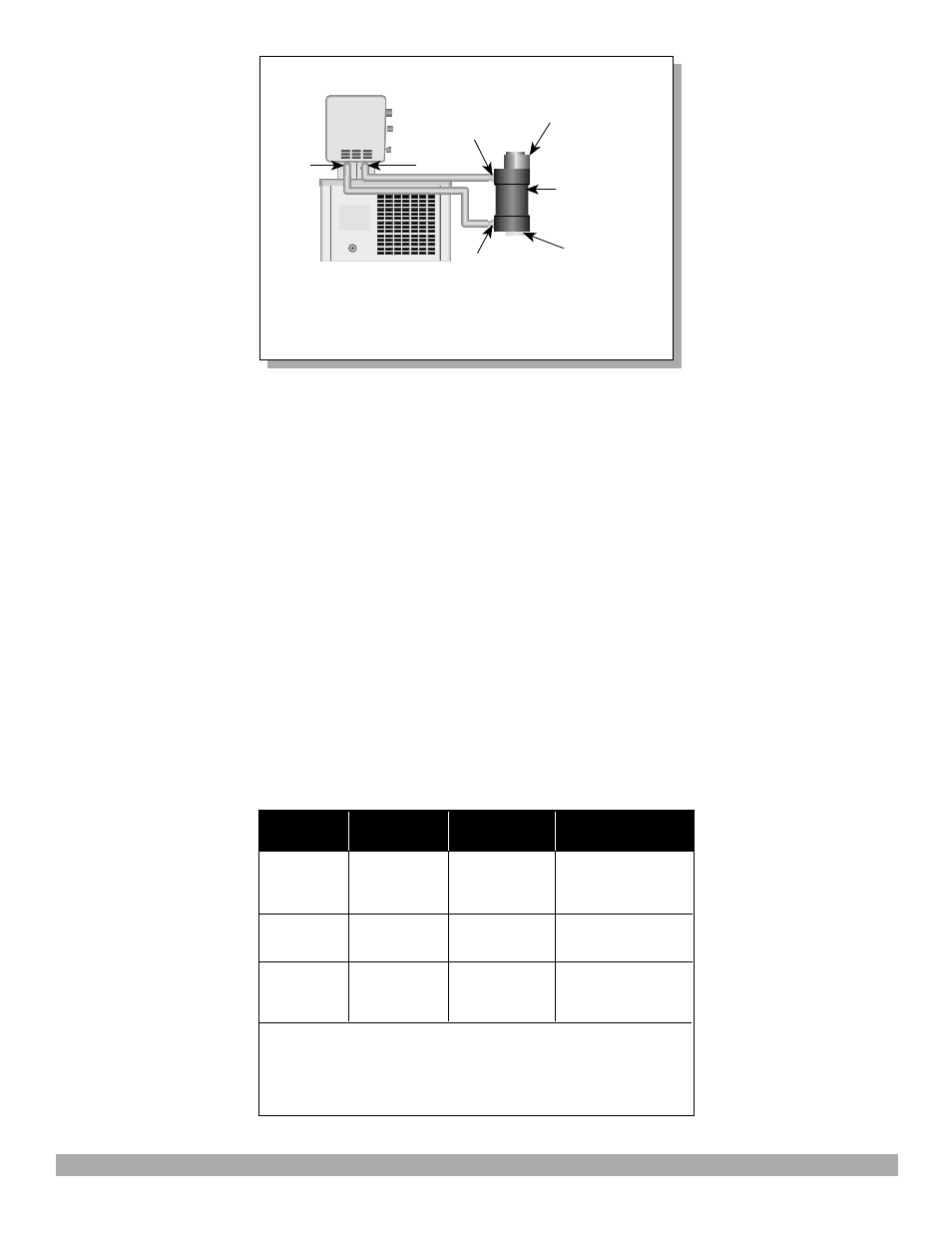

Figure 4: ULA-40Y water jacket connections

PUMP

INLET

PUMP

OUTLET

Water

Bath

Bath

Inlet

Bath

Outlet

ULA-40Y

Water Jacket

Jacket

Outlet

Jacket

Inlet

Sample

Tube

ULA-34

Tube End

Cap

Temp.

Bath