Brookfield Spiral Adapter User Manual

Page 12

Brookfield Engineering Labs., Inc.

Page 12

Manual No. M93-270-D0812

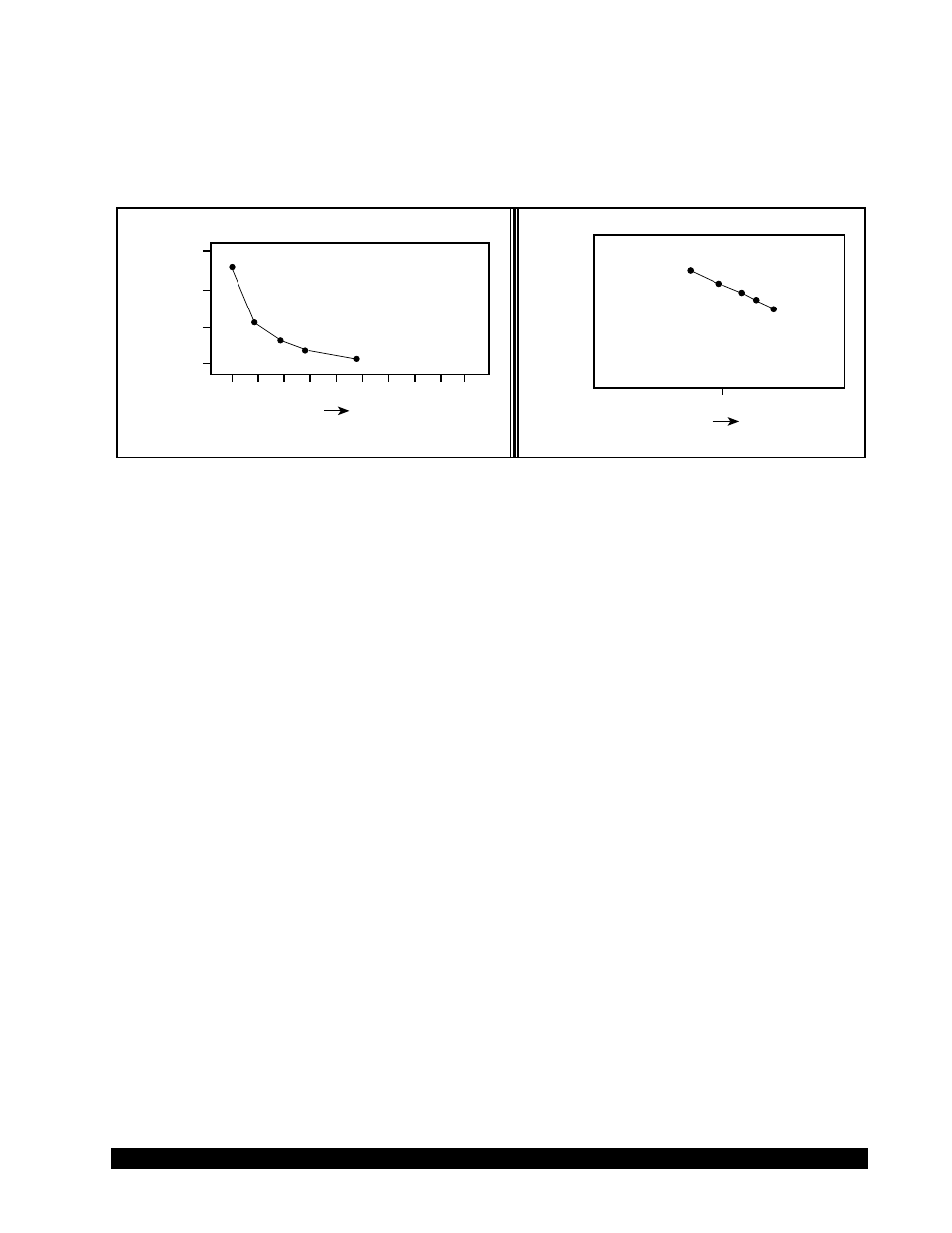

V.4 Application Example - Solder Paste

Applying solder paste is a printing operation that shears the materials as the paste “rolls” on

the stencil surface. Solder paste typically shows pseudoplastic behavior (exponential decrease

in viscosity with increasing shear rate) as shown in Figure 4.

1

10

100

LOG RPM

LOG VISCOSITY

(cP)

Slope of Line =

Shear Sensitivity Factor

10

6

10

5

7 x 10

5

6 x 10

5

5 x 10

5

4 x 10

5

0

5 10 15 20 25 30 35 40 45 50

RPM

VISCOSITY

(cP)

55

Figure 4

Figure 5

A plot of viscosity vs. RPM on a log/log scale approximates a straight line as shown in Figure 5.

The slope of the line provides information about the shear thinning of the paste. The absolute

value of the slope is called the “shear sensitivity factor”. Experimental correlations of these

slope values to actual printing properties allow the user to establish acceptable ranges of the

shear sensitivity factor.

The plots shown in Figures 4 and 5

can be generated easily when using Brookfield application

software. There is a math model (IPC Paste Analysis) included in the software which converts

viscosity vs. RPM data (Figure 4) into a log/log plot (Figure 5) and automatically computes

the “shear sensitivity factor.”

V.5 Cleaning the Spiral Adapter

Support the chamber and remove the clamp. Carefully lower the chamber off the spindle. Soak

in appropriate solvent. Remove spindle by lifting the lower shaft and holding it firm. Turn

the spindle nut to the right (counter-clockwise) to remove. Clean by wiping and soaking in

appropriate solvent. A soft brush is provided to aid in cleaning the threads. This brush should

also be cleaned in solvent.