Ii.3 temperature control of the sample – Brookfield Falling Ball KF20 User Manual

Page 11

Brookfield Engineering Labs., Inc.

Page

Manual No. M09-352-B04

to the air bubbles. Due to the design of the upper locking plug, air bubbles cannot get into

the sample tube.

• The sample must be free of air bubbles between the two locking plugs. The lid of the up-

per locking plug is attached and the temperature control (desired test temperature) must be

achieved. After proper temperature control is achieved, the upper cap is screwed on.

Do not heat the sample with the upper lid attached as pressure may build in the tube.

NOTE: Gas bubbles can be removed by warming up the sample for a short time (approxi-

mately 20 degrees above the measuring temperature with the upper locking plug

removed) or by lightly tapping on the lid of the upper locking plug.

II.3 Temperature Control of the Sample

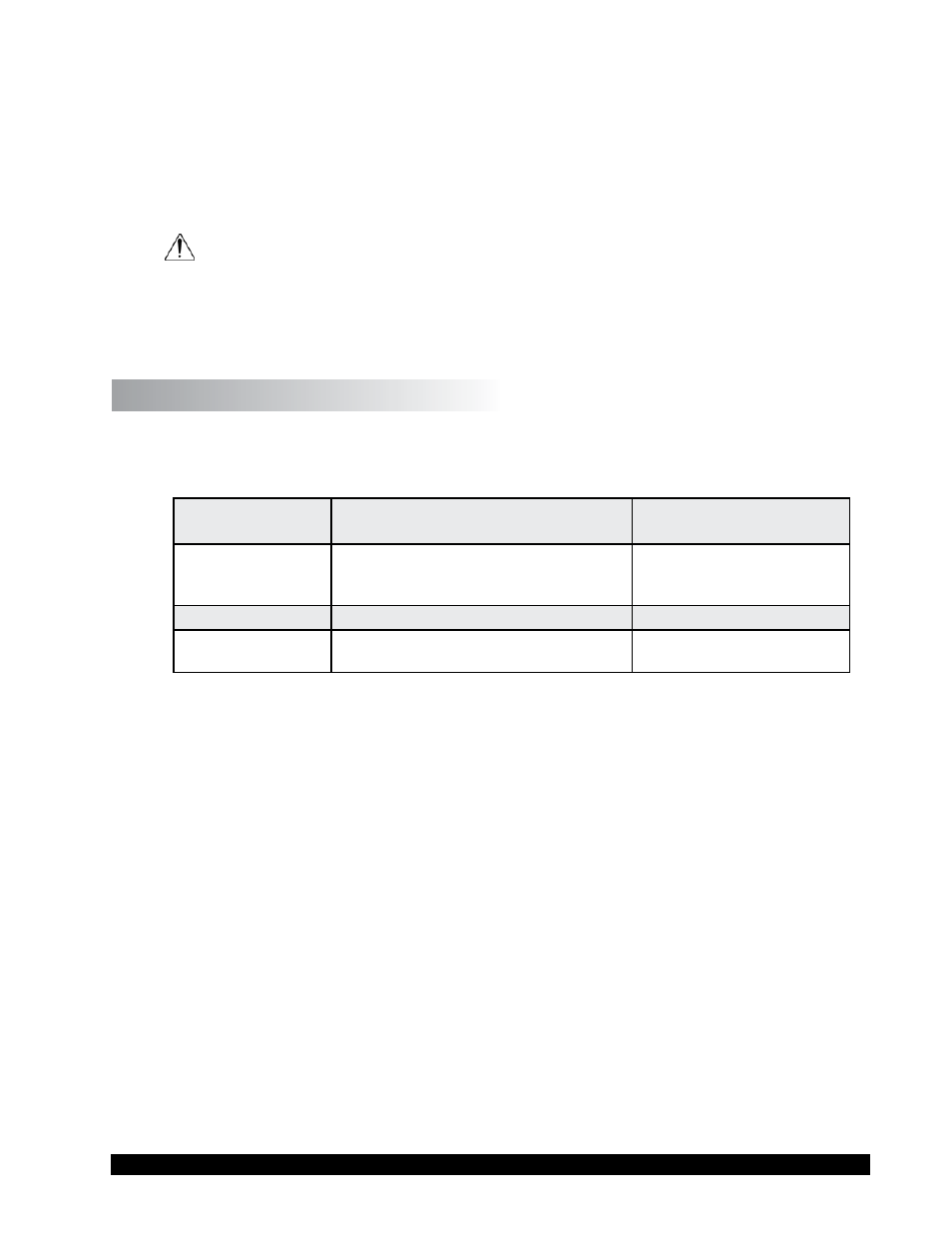

The following are suggested working fluids for the circulating temperature bath:

Temperature

Range

Bath Working Fluids

Tubing

-60 to +20°C

Water (deionized) - glycol-mixture; mixed

in accordance with the manufacturer’s

instructions for the temperature range

Insulated Perbunan tubing,

secured with tube band clips

+1°C to +90°C

Distilled water

Perbunan tube

+90°C to +150°C

Transparent thermostatic oil

Insulated Vitons tube, se-

cured with tube band clips

The tubing from the circulating bath should be pushed tightly onto the viscometer tubes. By

pulling gently, check whether the tubing is firmly attached. Tubing and circulating bath are

available on request from your Brookfield dealer. If the water bath jacket has condensation on

the glass, rub with alcohol.

The sample tube is sealed with the upper cap after temperature set point has been achieved.

Allow 30 minutes for thermal equilibrium.

Falling ball viscometers provide precise temperature control for the sample. By measuring

your sample at multiple temperatures, you can determine the temperature viscosity curve.