Ii. getting started ii. choice of balls, Ii.2 filling the sample tube – Brookfield Falling Ball KF20 User Manual

Page 10

Brookfield Engineering Labs., Inc.

Page 0

Manual No. M09-352-B04

II. GETTING STARTED

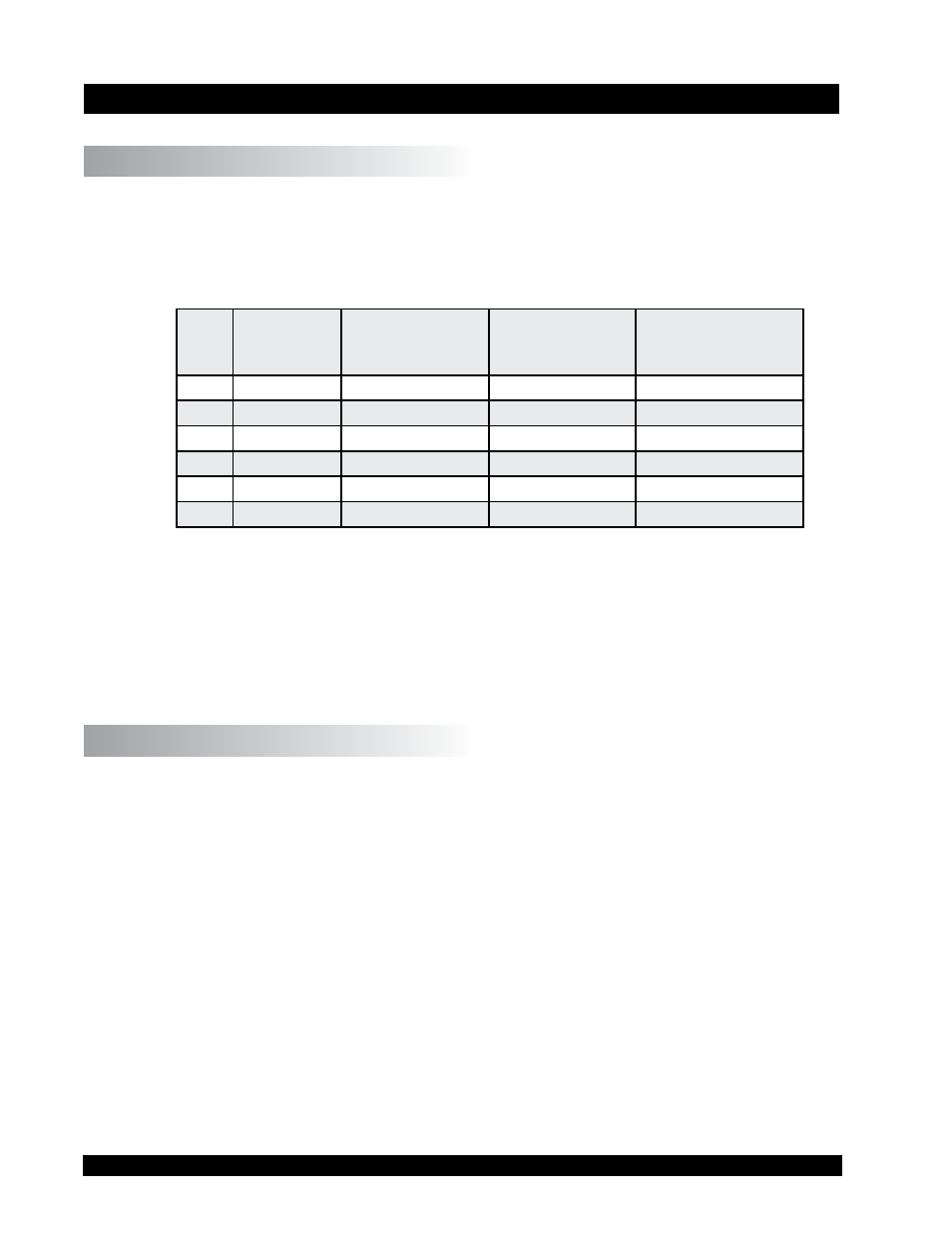

II. Choice of Balls

The balls are chosen in such a way that the minimum falling time is not less than what is shown

in the table and the maximum falling time is not greater than 300 s. The DIN 53015 indicates

that a falling time greater than 300 s is allowed, but for practical reasons, a shorter test time

makes more sense.

Ball

No.

Diameter

[mm]

Minimum falling

time [s]

Lower measur-

ing range limit

[

mPa•s

]

Upper

measuring range

limit [

mPa•s

]

1

15.81

60

0.5

10

2

15.60

30

2.5

130

3

15.60

30

20

700

4

15.20

30

200

7800

5

14.00

30

1000

45000

6

11.00

30

5500

70000

The specifications for the ball constant and the ball density are taken from the test certificate

which came with the equipment.

The exchange of balls or equipment components between different viscometers is not permit-

ted. Otherwise, the ball constants lose their validity.

When the falling time for the ball is less than the minimum time, turbulence may occur.

II.2 Filling the Sample Tube

To fill the sample tube:

• The sample tube is locked on the lower plate with the lower locking plug, seal, and cap.

• The liquid is filled up to approximately 25 mm beneath the top of the sample tube without

air bubbles. Use a glass filter to remove any impurities when introducing a liquid into the

tube.

• The ball is polished with the leather cloth and fibres are removed with the small cleaning

brush, before being inserted into the tube with the ball tweezers. The ball must not be touched

after polishing. The ball will travel to the bottom of the tube. Possible air bubbles in the

sample, or trapped below the ball, are removed with a suitable rod, by rotating the ball.

• Insert the upper locking plug with seal into the sample tube. In so doing, the sample must

enter the inside of the upper locking plug through the opening. The upper locking plug must

not be filled more than half way with the sample in order to minimize pressure build-up due