Radiance direct vent/natural vent gas heater, Table 2. air shutter adjustment, Table 1. injector orifice size matrix – Vermont Casting 3225 User Manual

Page 29

32

32

Radiance Direct Vent/Natural Vent Gas Heater

20004188

All Models

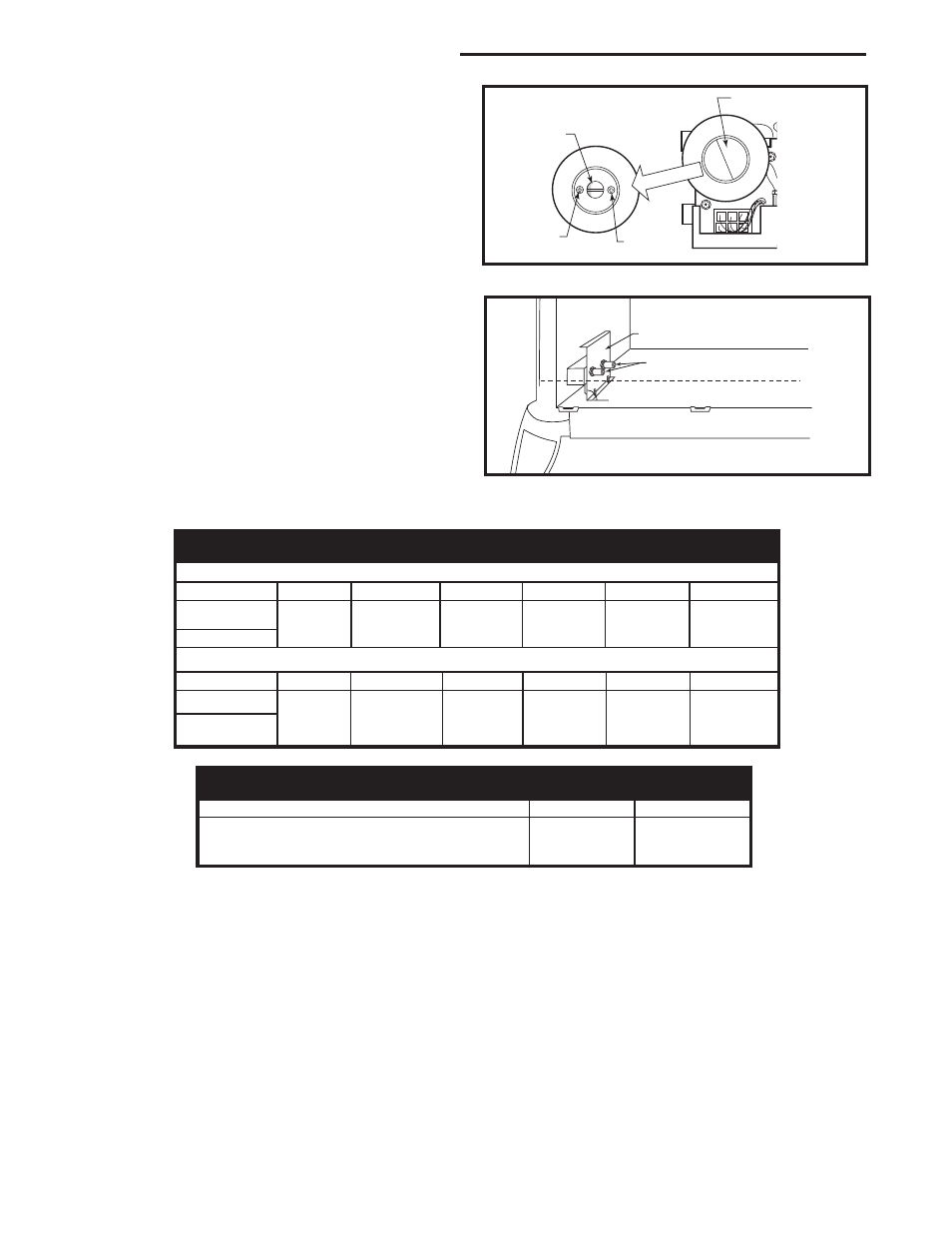

22. Replace burner. Slide the burner in at an angle

with left side lower than the right side. Slide the left

side onto the injectors, making sure the burner leg

remains at a 90° angle to the base. Lower the right

hand side down in to place. Make sure the burner is

as far left as possible and the injector shoulders are

inside the burner.

NOTE: It is very critical to keep the left burner leg,

which holds the injectors, at a 90° angle to the base.

(Fig. 61) This keeps the orifices aligned with the

tubes inside burner. Failure to do so could affect the

flame appearance and performance of the unit.

22.Place conversion label on valve.

23.Reinstall the right and left log bracket assembly.

24.Reinstall the rear log bracket.

25.Replace logs.

26.Replace glass and stove front.

Conversion is complete.

FP1037b

comfort valve

convert

3/6/01 djt

LOCAL

REMOTE

O

N

•

PILO

T

OFF

•

LED

Motor Top Cap

Center

Plunger

Blue - NG

Red - LP

FP1037b

Fig. 60 Depress and turn center plunger.

Valve

Model

Natural Gas

LP

RDVOD, RDVOD with

Vermont Castings Draft Hood Z31D00 FSDHAG

1”

Fully Closed

Table 2. Air Shutter Adjustment

Minimum rear injector air inlet openings.

Fig. 61 Remove and replace injector orifices.

ST353a

injector orifice

replace

3/21/00 djt

90°

Left Burner Leg

Injector Orifices

ST353a

Conversion to Natural Gas

Input (BTU/h)

Kit #

Front

Part #

Rear

Part #

Minimum Maximum

000-5002

000-5009

#51

30000449

#40

20004263

25,000

35,000

Conversion to LP

Input (BTU/h)

Kit #

Front

Part #

Rear

Part #

Minimum Maximum

000-5003

000-5010

#57

20004587

#54

20000130

27,500

35,000

Table 1. Injector Orifice Size Matrix