Dillon DynaSwitch User Manual

Page 11

11

2-4

Other Installation

Possibilities

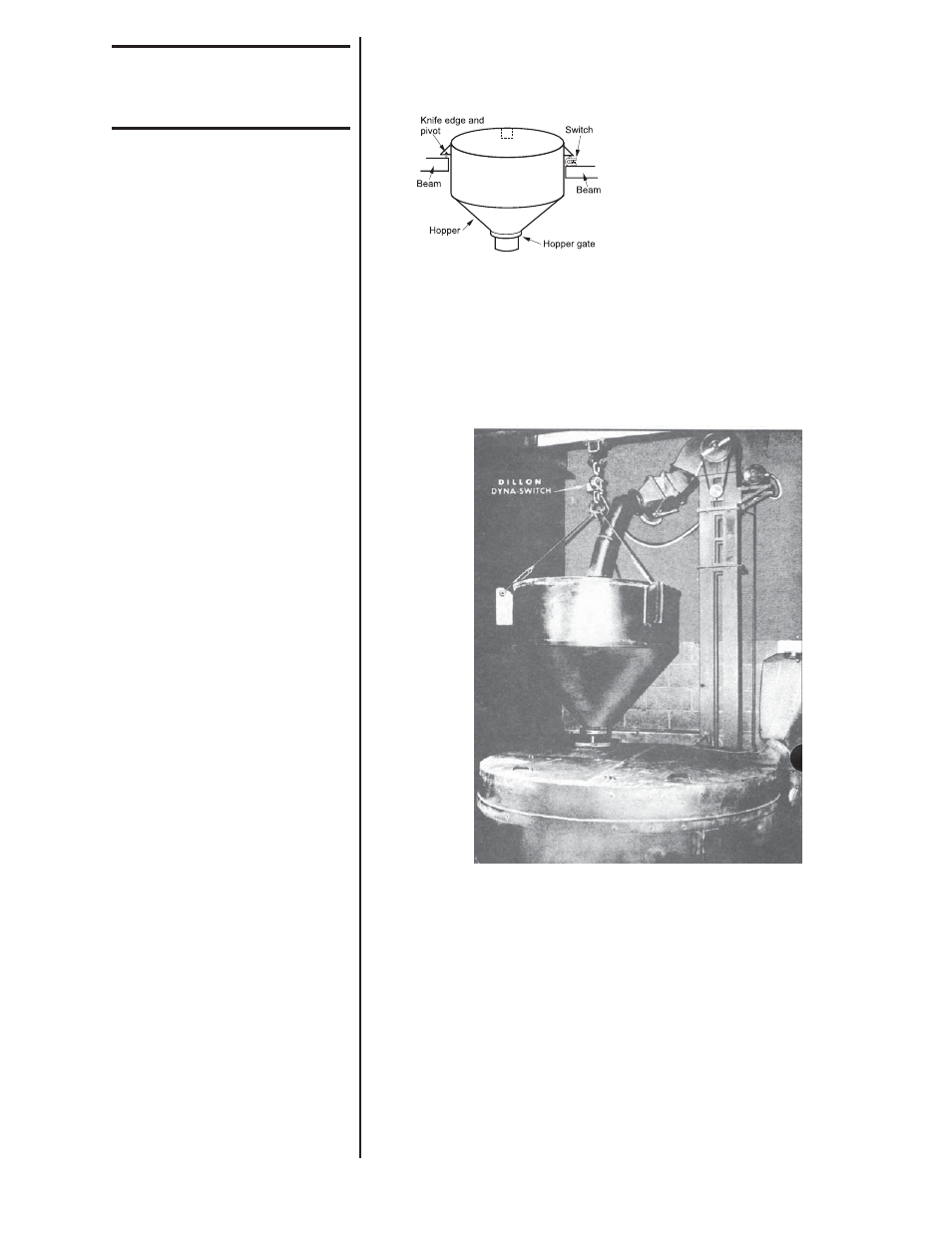

Figure 2-E and 2-F show other uses for the Dynaswitch when either

tension or compressions loads are present.

Batching operations at preset load

points are greatly simplified by

means of economical Dillon

Dynaswitches. Figure 2-E shows a

typical hopper with 3 point suspen-

sion. Dynaswitch under one sus-

pension point is set for 1/3 maxi-

mum load. It opens hopper gate

automatically at this point. Contents

of tank should preferably be liquid,

since solid materials tend to pile

and cause erroneous results.

Figure 2-E

Figure 2-F

Figure 2-F shows an example of using the Dynaswitch in an automatic

control function. Sand used in foundry operations is brought up from the

floor below by conveyor. It falls into the chute and then spills into the

hopper. The hopper itself is suspended from the Dynaswitch at upper left.

The Dynaswitch is set to open the conveyor motor circuit at 1000 pounds

which represents a full hopper. At the same instant, a trap in the bottom of

the hopper also opens permitting contents to flow out into a mixer below. A

time delay switch on the hopper trap holds it open until all sand has been

discharged at which time the reduced load on the Dynaswitch causes it to

again close the conveyor motor circuit and repeat the cycle endlessly.

The Dynaswitch is also acting as a precision scale since it is set to func-

tion at a specific load point. Any form of batching operation can be easily

automated by this simple arrangement.