Drive component maintenance, A. motor, blower wheel, and coupling replacement – Beckett SDC 12V User Manual

Page 9

9

12Vdc SDC Burner Manual

Drive Component

Maintenance

A. Motor, Blower Wheel, and Coupling

Replacement

The motor will require replacement if the proper voltage is

measured at the motor input, and the motor will either not

run, or the current draw with a free running pump exceeds

10% of the rated current.

To replace the burner motor, coupling and/or blower wheel

perform the following steps.

Before servicing, turn off and/or disconnect all power

to the burner.

Disconnect the burner motor wires.

Remove the bolts securing the motor to the burner

housing.

Remove the motor, coupling, and blower wheel.

Loosen the set screw on the blower wheel to slide

the existing wheel off the shaft.

Slide the new blower wheel onto the old shaft (after

thoroughly cleaning housing) and/or slide the old

blower wheel onto the new motor shaft.

When replacing the blower wheel, ensure the wheel

is centered between the two sides of the burner

housing as shown.

1.

2.

3.

4.

5.

6.

7.

Rotate the blower wheel until the setscrew is centered

on the fl at of the motor shaft. Tighten the setscrew to

secure the wheel.

Slide the motor coupling on the motor shaft, then

install the motor on the burner housing. Ensure that

the motor coupling fi ts between the motor shaft and

the pump shaft inside the housing. Tighten the motor

retaining screws. Reconnect the wires.

Restore power, start the burner and perform

the combustion test described previously in this

manual.

8.

9.

10.

Figure 7. – Blower Wheel

Section: Drive Component Maintenance

CENTER WHEEL FOR EQUAL

DISTANCE FROM HOUSING SIDES

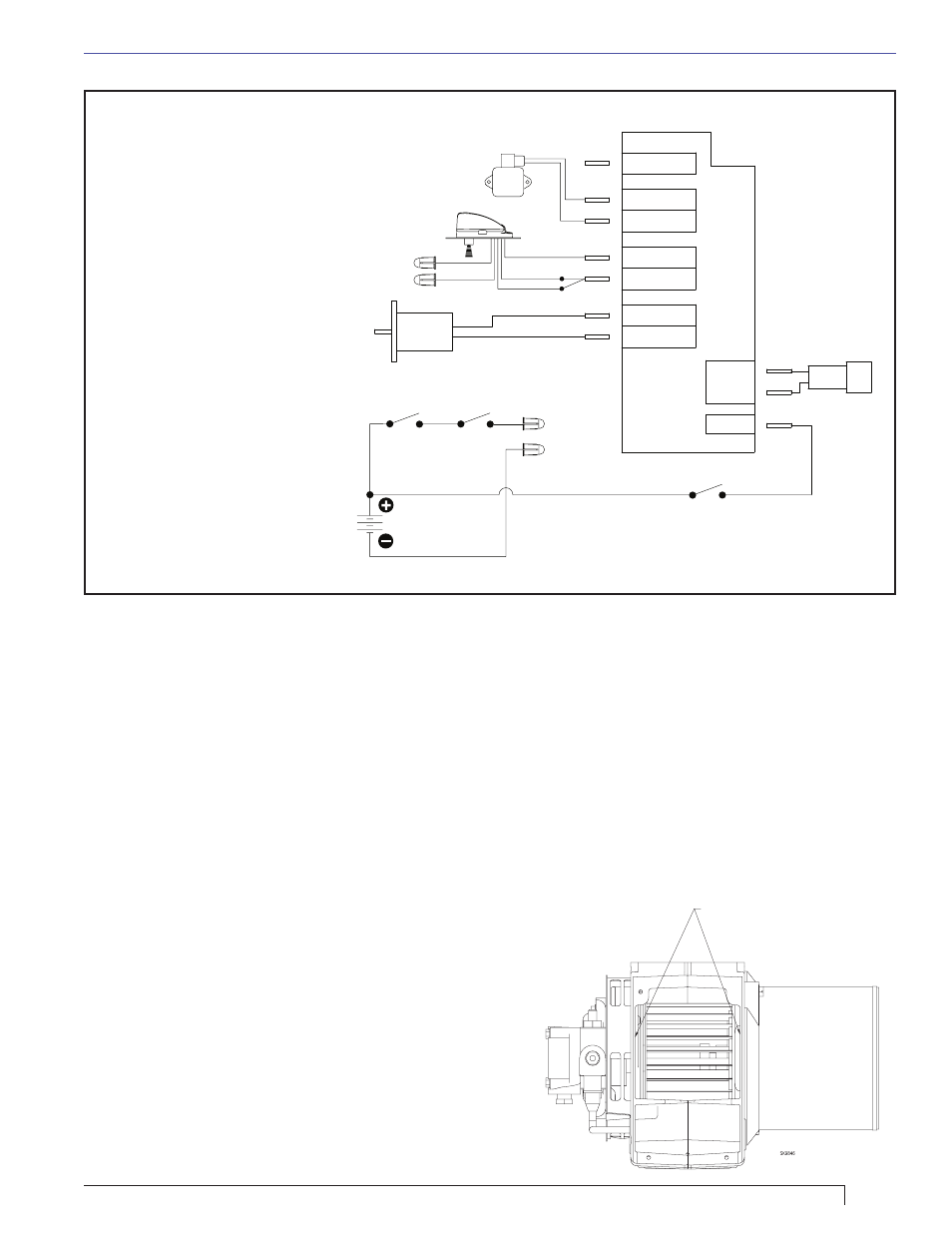

Figure 6C. Typical Wiring with 7556 Primary Safety Control

Notes:

1. Wires are to be sized to prevent a voltage

drop between the battery and the burner with the

burner running at full load.

2. Fuse Sizes (inside control):

Motor = 30 Amp

Igniter, Control, Valve, & Alarm = 10 Amp

3. Hard-wire burner ground to battery. Do NOT

use chassis ground system.

4. Input power to the control’s +12 Volt wire shall

be provided from a fused service switch, rated at

50 amps or less.

5. Motor-off delay on a 7556P will be disabled

if the safety and operating limits as shown in

Figure 6C interrupt power to the control’s red

+12 Volt wire.

6. Do not wire power directly to the burner motor.

Only wire the motor as shown in Figure 6C. If

instant burner heat is required by the application,

purchase or program a control with a long motor-

off delay time, which will ensure instant heat if a

new call for heat is received within the motor-off

delay time.

7. Igniter Yellow leads are capped and not used.

Bundle with the other leads in the wiring box with

a cable tie.

8. The igniter Blue-White striped

and solid White leads are combined

with the 3274001 “Y” connector

and attached to the primary control

igniter spade terminal.

24V

POWER

MAIN

ALARM

VALVE

GND (VLV)

IGNITER

GND (IGN)

MOTOR

GND (MTR)

ON/OFF/RESET

HIGH

LIMIT

THERMOSTAT

OIL

VALVE

SK10089

MOTOR

IGNITER

RED WIRE

BLACK WIRE

ENABLE

CAD

CELL

CAD CELL

Note 7

Note 8