Carrier 38TRA User Manual

Page 3

connected by 15 ft of field-supplied or factory-accessory tubing.

Check refrigerant charge for maximum efficiency. (See Step

8—Checking Charge.)

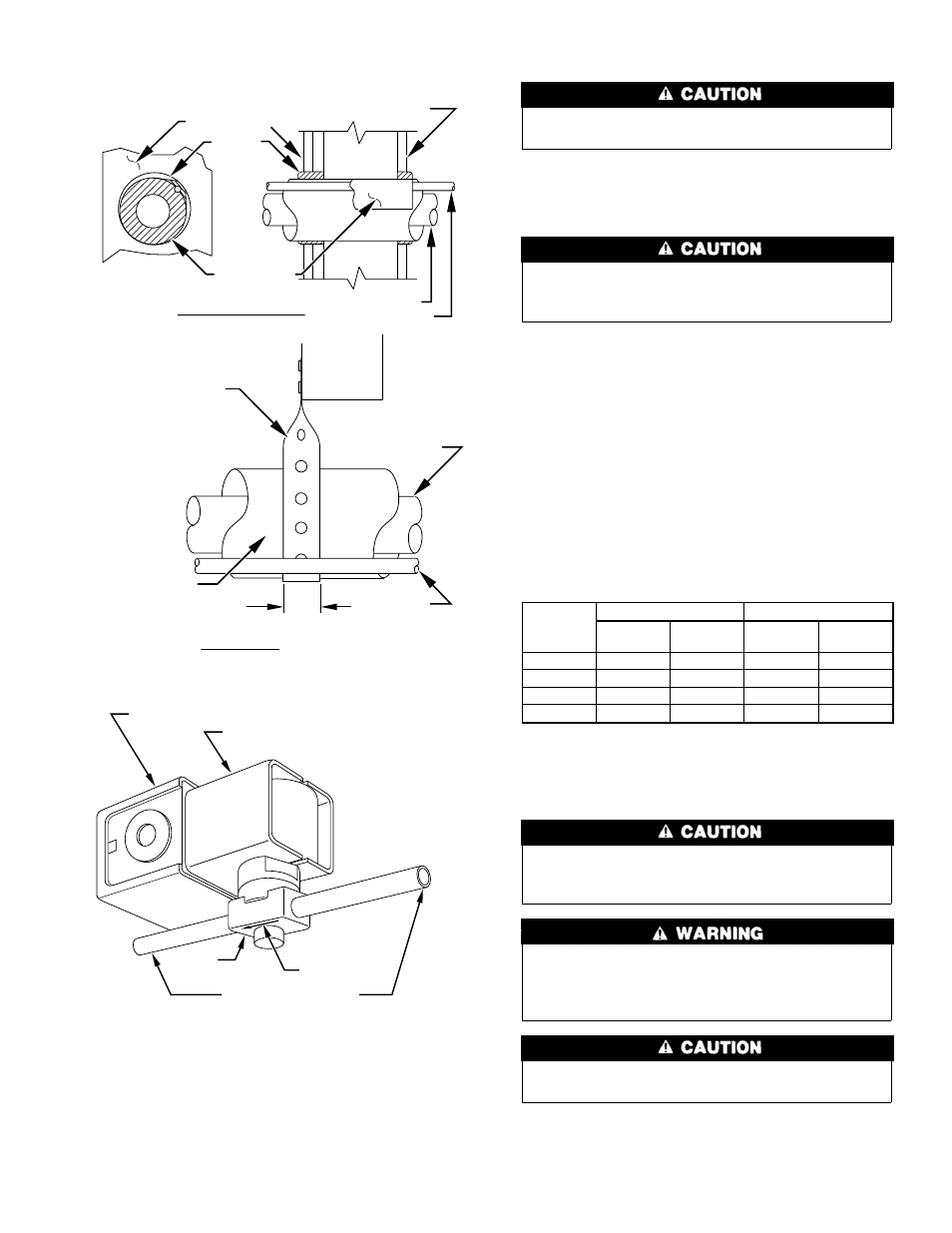

INSTALL SOLENOID VALVE IN LIQUID TUBE

Solenoid valve must be energized during evacuation for

effective evacuation.

Before making liquid tube connections, install factory-supplied

solenoid valve on indoor liquid fitting. (See Fig. 4.) Be sure to use

flare adapter supplied with the indoor coil when making connec-

tions.

If a field-supplied control power source is needed when

adding solenoid, wiring must comply with local codes and

NEC requirements.

1. Remove coil liquid connection cap and discard.

2. Mount solenoid valve on liquid tube, making sure valve flow

arrow points toward indoor coil. Mount valve in any position

except valve body at top and electric coil at bottom. (See Fig.

4.) The solenoid valve is to be installed a maximum of 24 in.

from indoor coil.

3. Braze valve onto end of liquid tube using silver bearing or

non-silver bearing brazing material. Consult local code re-

quirements.

4. Braze flare adapter onto outlet end of the solenoid valve.

5. Wire solenoid coil into system control circuit as shown in Fig.

6.

Table 1—Refrigerant Connections and Recom-

mended Liquid and Vapor Tube Diameters (In.)

UNIT

SIZE

LIQUID

VAPOR

Connect

Diameter

Tube

Diameter

Connect

Diameter

Tube

Diameter

018, 024

3/8

3/8

5/8

5/8

030, 036

3/8

3/8

3/4

3/4

042, 048

3/8

3/8

7/8

7/8

060

3/8

3/8

7/8

1-1/8

Notes: 1. Tube diameters are for lengths up to 50 ft. For tubing lengths greater

than 50 ft, consult Long-Line Application Guideline.

2. Do not apply capillary-tube indoor coils to these units.

REFRIGERANT TUBING — Connect tubing to fittings on out-

door unit vapor and liquid service valves. (See Fig. 2.)

A brazing shield MUST be used when tubing sets are being

brazed to the service valves to prevent damage to the painted

unit surface.

Relieve pressure and recover all refrigerant before system

repair or final unit disposal to avoid personal injury or death.

Use all service ports and open all flow control devices,

including solenoid valves.

To avoid valve damage while brazing, service valves must be

wrapped with a heat-sinking material such as a wet cloth.

SWEAT CONNECTION — Use refrigerant grade tubing. Service

valves are closed from factory and ready for brazing. After

wrapping the service valve with a wet cloth, the tubing set can be

brazed to the service valve using either silver bearing or non-silver

Fig. 3—Piping Installation

A92469

OUTDOOR WALL

CAULK

INDOOR WALL

LIQUID LINE

VAPOR LINE

INSULATION

JOIST

INSULATION

HANGER STRAP

(AROUND VAPOR

LINE ONLY)

VAPOR LINE

LIQUID

LINE

THROUGH THE WALL

SUSPENSION

1

″

MIN

NOTE:

AVOID CONTACT BETWEEN TUBING AND STRUCTURE

Fig. 4—Solenoid Valve Installation

A87044

ELECTRICAL JUNCTION

ELECTRICAL COIL

VALVE

FLOW ARROW

STRAIGHT

3

/

8

IN. STUD

NOTE: System flow direction

must match arrow on

bottom of body.

3