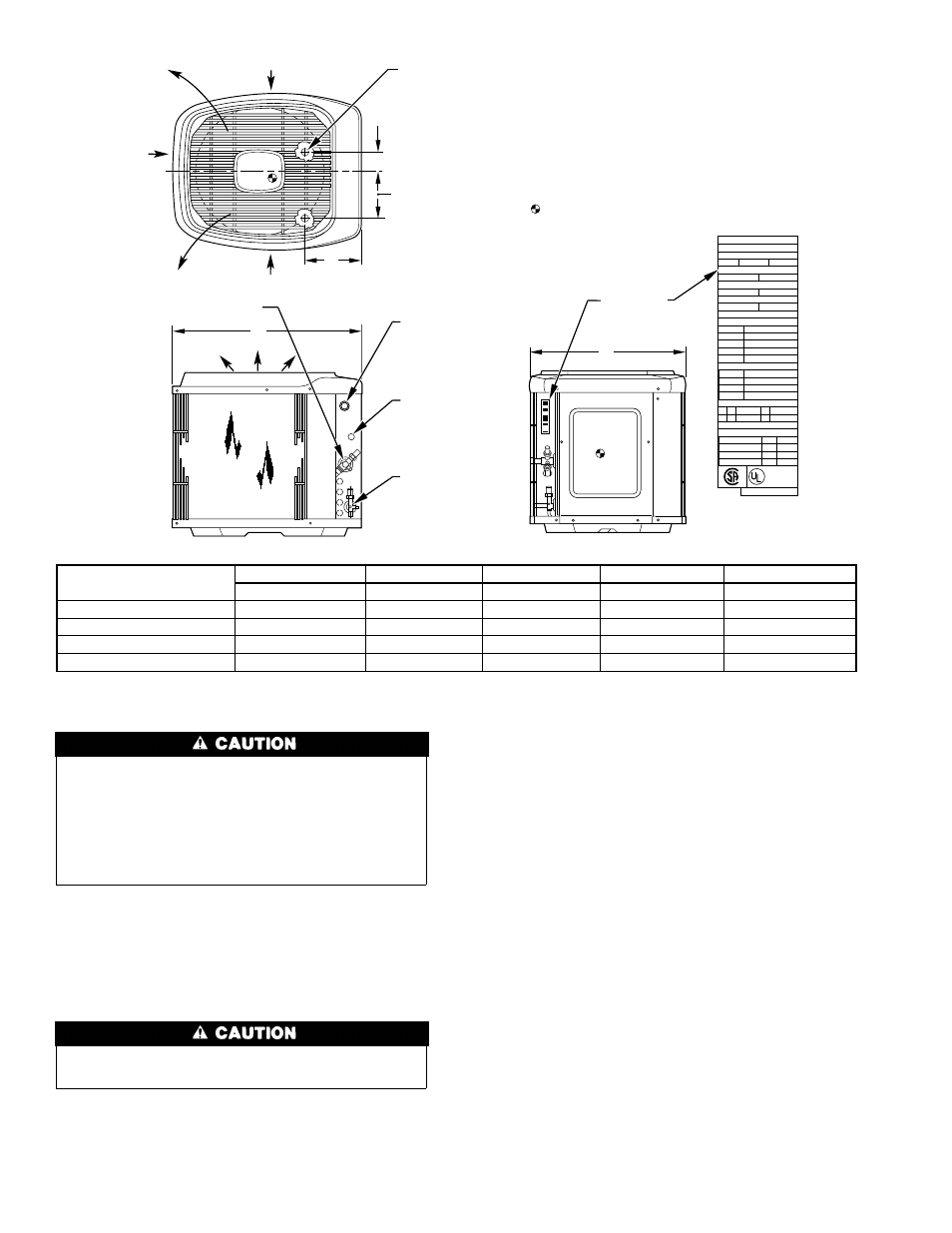

Fig. 2—unit reference drawing – Carrier 38TRA User Manual

Page 2

DO NOT BURY MORE THAN 36 IN. OF REFRIGERANT

TUBING IN GROUND. If any section of tubing is buried,

there must be a 6-in. vertical rise to the valve connections on

the outdoor unit. If more than the recommended length is

buried, refrigerant may migrate to cooler buried section

during extended periods of unit shutdown, causing refrigerant

slugging and possible compressor damage at start-up.

Step 4—Make Piping Connections

Outdoor units may be connected to indoor sections using accessory

tubing package or field

−

supplied refrigerant grade tubing of

correct size and condition. For tubing requirements beyond 50 ft,

consult Long-Line Application Guideline which is available at

your local distributor.

In some cases noise in the living area has been traced to gas

pulsations from improper installation of equipment.

INSTALLATION RECOMMENDATIONS

1. Locate the unit away from windows.

2. Ensure that vapor and liquid line diameters are appropriate to

the capacity of the unit. (See Table 1.)

3. Run refrigerant tubes as directly as possible by avoiding

unnecessary turns and bends.

4. Leave some slack between the structure and the unit to absorb

vibration.

5. When passing refrigerant tubes through the wall, seal the

opening with RTV or other pliable silicon-based caulk. (See

Fig. 3.)

6. Avoid direct lineset contact with water pipes, ductwork, floor

joists, wall studs, floors, and walls.

7. Do not suspend refrigerant tubing from joists and studs with a

rigid wire or strap which comes in direct contact with the

tubing. (See Fig. 3.)

8. Ensure that tubing insulation is pliable and completely sur-

rounds the vapor line.

9. When necessary, use hangar straps which are 1 in. wide and

conform to the shape of the tubing insulation. (See Fig. 3.)

10. Isolate the hangar straps from the insulation by using metal

sleeves bent to conform to the shape of the insulation.

If refrigerant tubes or indoor coil is exposed to atmospheric

conditions for longer than 5 minutes, it must be evacuated to 500

microns to eliminate contamination and moisture in the system.

OUTDOOR UNITS CONNECTED TO FACTORY-APPROVED

INDOOR UNITS — Outdoor unit contains correct system refrig-

erant charge for operation with indoor unit of the same size when

Fig. 2—Unit Reference Drawing

UNIT

SIZE

A

B

C

D

E

In.

In.

In.

In.

In.

018

27-1/2

22-1/2

8-3/16

2-13/16

6-15/16

024-048

34-15/16

30

8-3/16

4

9-3/4

060 (301 Series)

45

38-5/8

8-9/16

5-15/16

11-13/16

060 (311 Series)

34-15/16

30

8-3/16

4

9-3/4

A92471

AIR DISCHARGE

3

/

8

″

DIA

LIQUID

LINE CONN

FIELD CONTROL

SUPPLY CONN

7

/

8

″

DIA HOLE

AIR DISCHARGE

AIR DISCHARGE

AIR IN

AIR IN

3/8"

DIA TIEDOWN KNOCKOUTS

(2) PLACES IN BASEPAN

C

L

UNIT RATING

PLATE

1. ALLOW 30

″

CLEARANCE TO SERVICE END OF

UNIT, 48

″

ABOVE UNIT, 6

″

ON ONE SIDE, 12

″

ON REMAINING SIDE, AND 24

″

BETWEEN

UNITS FOR PROPER AIRFLOW.

2. MINIMUM OUTDOOR OPERATING AMBIENT IN COOLING MODE IS

55° F (UNLESS LOW AMBIENT CONTROL IS USED) MAX 125° F.

5. SERIES DESIGNATION IS THE 13TH POSITION OF THE UNIT

MODEL NUMBER.

6. CENTER OF GRAVITY

NOTES:

ACCESS

PANEL

FIELD POWER SUPPLY CONN

7

/

8

″

DIA HOLE WITH

1

1

/

8

″

DIA KNOCKOUT

AND

1

3

/

8

″

DIA KNOCKOUT

A

C

AIR IN

E

D

B

VAPOR LINE CONN

INDIANAPOLIS IN

46206

313948-401

REV A

MAX CKT-BKR

MAX HACR CKT-BKR

MAX FUSE

TYPE

MINIMUM CIRCUIT AMPS

LO

HI

DESIGN/TEST PRESSURE GAGE

FLA

HZ

PH

VOLTS AC

LRA

RLA

HZ

PH

VOLTS AC

MAX

PH

LBS

PISTON

MODEL

PROD

SERIAL

N/A

USA

N/A

CANADA

MAX OVERCURRENT PROTECTIVE DEVICE

kPa

kPa

PSI

PSI

FAN MOTOR

COMPRESSOR

SUITABLE FOR OUTDOOR USE

MIN

HZ

Kg

VOLTS

POWER SUPPLY

ID

OD

FACTORY CHARGED R-22

®

®

PERMISSIBLE VOLTAGE AT UNIT

CARRIER CORP

2