G and l temperature switches, Temperature switches, Thermowells – Pilgrim MULTIFUNCTION PRESSURE AND TEMPERATURE SWITCHES User Manual

Page 6: Which can be used with 2

6

NOTES:

1. Switches may generally be set between 15% and 100%

of nominal range on increasing or decreasing

temperature. Consult factory for applications where

setpoints must be lower.

2. All deadbands are given in

O

F.

TEMPERATURE RANGE SELECTION

3. Deadbands for LTA and GTA are

adjustable between the values shown.

4. Deadbands for LTS, GTS, LTD and GTD

models are fixed within the range of values shown.

Manufacturing and parts variances result in variation

from one unit to another.

Approximate Deadband

(2)

Nominal Range

Max.

LTA-GTA

(3)

LTS-GTS

(4)

LTD-GTD

(4)

Temp.

Switch Element

°

F

°

C

°

F

J, H

G

J, H

K, F

P

GG

JJ, HH

KK,FF

PP

-40 to 60

-40 to16

400

18-90

4.0-10

9.0-18

1.5-3

2-5

4-10

9.0-18

1.5-3

2-5

0 to 100

-20 to 40

400

30-90

5.0-15

10-30

1.5.5

3-7

5-15

10-30

1.5-4.5

3-7

75 to 205

20 to 95

400

34-120

6.0-18

10-34

3-5.5

3-8

6-18

10-34

3-5.5

3-8

150 to 260

65 to125

400

25-100

3-13

9.0-25

1.5-4

3-7

3-13

9.0-25

1.5-4

3-7

235 to 375

110 to 190

500

35-130

6-19

10-35

2-5.5

3-8

6-17

10-35

2-5.5

3-8

350 to 525

(5)

175 to 275

700

40-165

5-27

15-40

3-7

3.5-11

5-27

15-40

3-7

3.5-11

500 to 750

(5)(6)

260 to 400 900 50-200

20-36

36-60

5-10

6-21

20-36

36-60

5-10

6-21

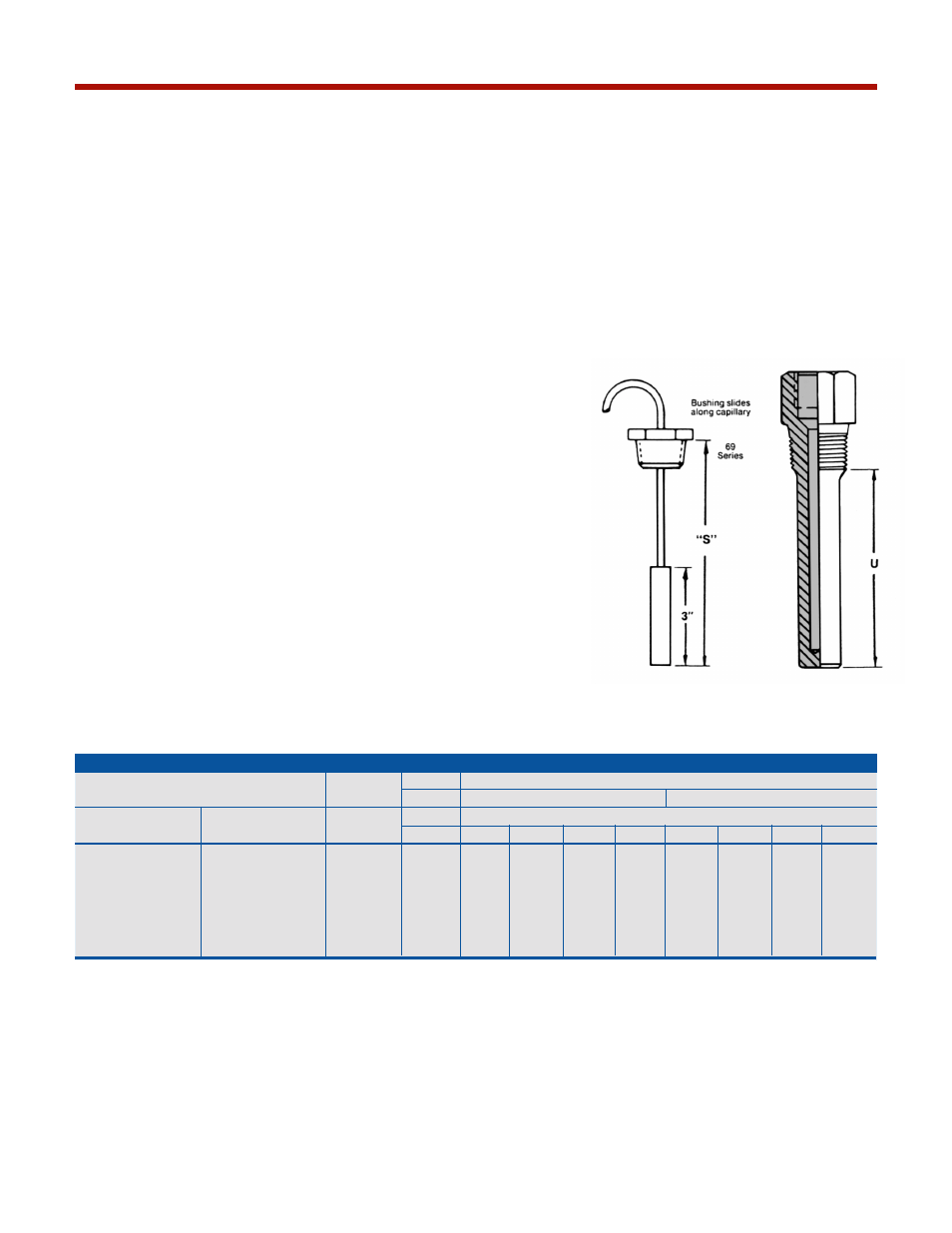

Temperature Switches

G- and L-Series temperature

switches feature a SAMA Class II

vapor pressure thermal system.

This system provides quick,

accurate response to process

temperature changes with negli-

gible ambient temperature effects.

This is inherent in the design due to

the precise relationship between

temperature and pressure accord-

ing to the vapor pressure laws. A

wide selection of sensing bulb and

armored capillary lengths are

available. The vapor pressure

system design features small bulb

sizes, making installation easy and

cost-effective.

All models feature

±

1 percent of

span setpoint repeatability with

very high overtemperature ratings.

These standard designs perform

well in applications where shock

and vibration could be a problem

and should be used with Ashcroft

thermowells for bulb protection and

ease of installation and maintenance.

Thermowells

Thermowells must be used on any

application where the stem of the

temperature switch may be ex-

posed to pressure, corrosive fluids

or high velocity. Additionally, the

use of a thermowell permits instru-

ment interchange or calibration

check without disturbing or closing

down the process.

Ashcroft temperature switches

have bulb diameters to match

3

/

8

˝

nominal bore thermowells. The

bulbs have a sensitive portion

length of 2

1

/

4

˝ which can be used

with 2

1

/

2

˝ “U” dimensioned

thermowells or longer. For maxi-

mum accuracy, a thermowell “U”

dimension should be selected to

permit complete immersion of the

sensitive portion plus 1˝ when

measuring the temperature of

liquids; an extra 3˝ should be

allowed when measuring the

temperature of gases.

Thermowell bushings should be

used with remote mount tempera-

ture switches. We recommend the

standard 3˝ bulb and code 69

Series bushings for use with any

thermowell “U” dimension. A split

rubber grommet allows easy

installation and “S” dimension

adjustment.

G and L TEMPERATURE SWITCHES

5. Not available with 2

3

/

4

”stem

6. Available with remote mount thermal system only.