Plus, Other duragauges, Ashcroft – Pilgrim Pressure Gauges Process User Manual

Page 5: Duragauge, Pressure gauge

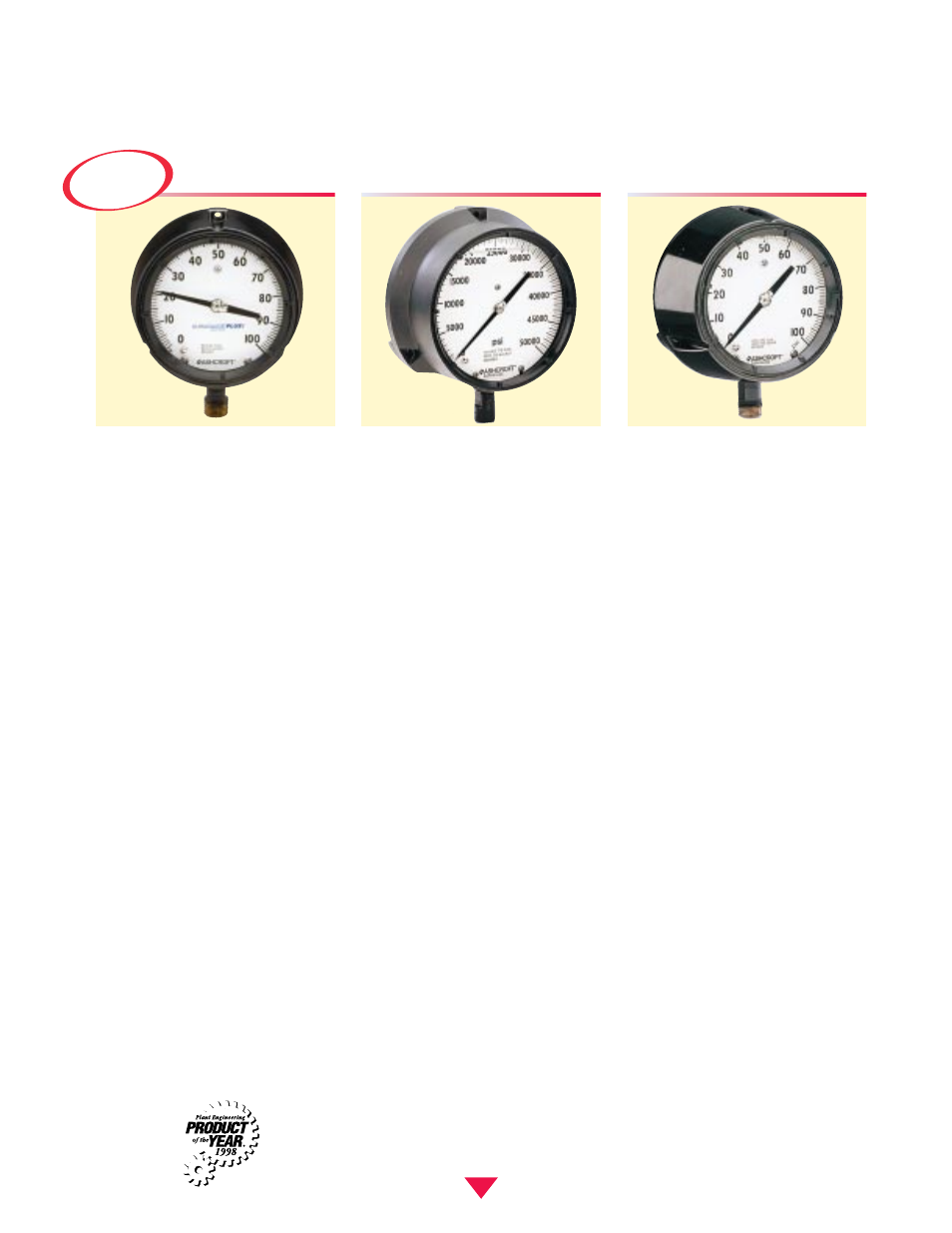

PLUS!

™

Performance Duragauge

®

An exclusive, new, optional feature

provides virtually liquid-filled perfor-

mance in a dry gauge.

The Ashcroft

PLUS!

™

feature is a

patent-pending design incorporated into

the industry-standard Ashcroft pressure

gauge.

PLUS! is available in any Dura-

gauge case style material or range.

Historically, pulsation and vibration

have reduced gauge life and made

gauges difficult to read.

Customers have had no alternative to

liquid-filled gauges to solve vibration

and pulsation problems, until now!

Advantages Versus

Liquid-Filled Gauges

• Saves money

- Lower purchase price versus liquid-

filled gauges

- Eliminates costly specialty fills

- Allows easy standardization to

reduce mis-applications

• Eliminates possibility of leaks

• Lighter weight . . . easier to handle

• Eliminates liquid-fill lines . . .

easier to read

• Easy recalibration

• Wider ambient temperature range

than glycerin

• Eliminates disposal and environmen-

tal issues

Advantages Versus Dry Gauges

• Steady pointer . . . same as liquid-

filled gauges

• 100% longer life gauges . . .

reduces gauge usage 50%!

Other Duragauges

Ashcroft

®

Duragauge

®

Pressure Gauge

High Pressure Duragauge

®

The Ashcroft high pressure Dura-

gauge has a helical wound Inconel

Bourdon tube which is capable of with-

standing vibration without a zero shift or

change in calibration. Because of the

length of the helical tube, stresses are

minimized and the tip travel increased;

this permits the use of a low ratio move-

ment, which decreases wear from fric-

tion and increases gauge life. For use

on high pressure test applications, metal

and concrete water cutting equipment,

and other high pressure applications.

Features of the gauge include ASME

B40.1, grade 2A,

1

⁄

2

of 1% full scale, 6˝

dial, lower or back connection, solid

front aluminum case for wall or flush

mounting. Inconel 718 Bourdon tube

and 316 stainless steel socket is stan-

dard. A hermetically sealed, field liquid-

fillable case is standard. The Ashcroft

high pressure Duragauge is available in

ranges of 50,000 psi, 80,000 psi, and

100,000 psi with a standard

1

⁄

4

˝ high

pressure tubing connection.

Receiver Duragauge

®

Used in conjunction with pneumatic

transmitters, Ashcroft receiver gauges

indicate pressure, temperature, flow, or

any information that can be transmitted

by proportional variations in air pressure.

For information concerning other receiv-

er gauges offered, consult Customer

Service, Stratford, Connecticut.

Liquid-Filled Duragauge

®

Liquid-filled Duragauges have tradi-

tionally been used in applications where

there is excessive vibration and pulsa-

tion. Vibration can cause rapid move-

ment resulting in loss of accuracy and

possibly complete destruction of the

gearing. Pulsation can generate mil-

lions of pressure cycles causing Bour-

don tube fatigue and reduced service

life. The field conversion kit contains an

Ashcroft patented elastomeric back

which provides compensation for ambi-

ent temperature variation while provid-

ing all the features of a blow-out back.

The sealed case completely excludes

dusty or corrosive environmental condi-

tions. Since vibration and pulsation fre-

quently occur together, all liquid filled

Duragauges are fitted with a throttle

plug screwed into the socket. This can

easily be removed or changed for vis-

cous or particulate containing media.

Seven sizes are available from .006 to

.070 diameter.

5

PLUS!

Performance