How to order, Ashcroft, Duragauge – Pilgrim Pressure Gauges Process User Manual

Page 13: Pressure gauge

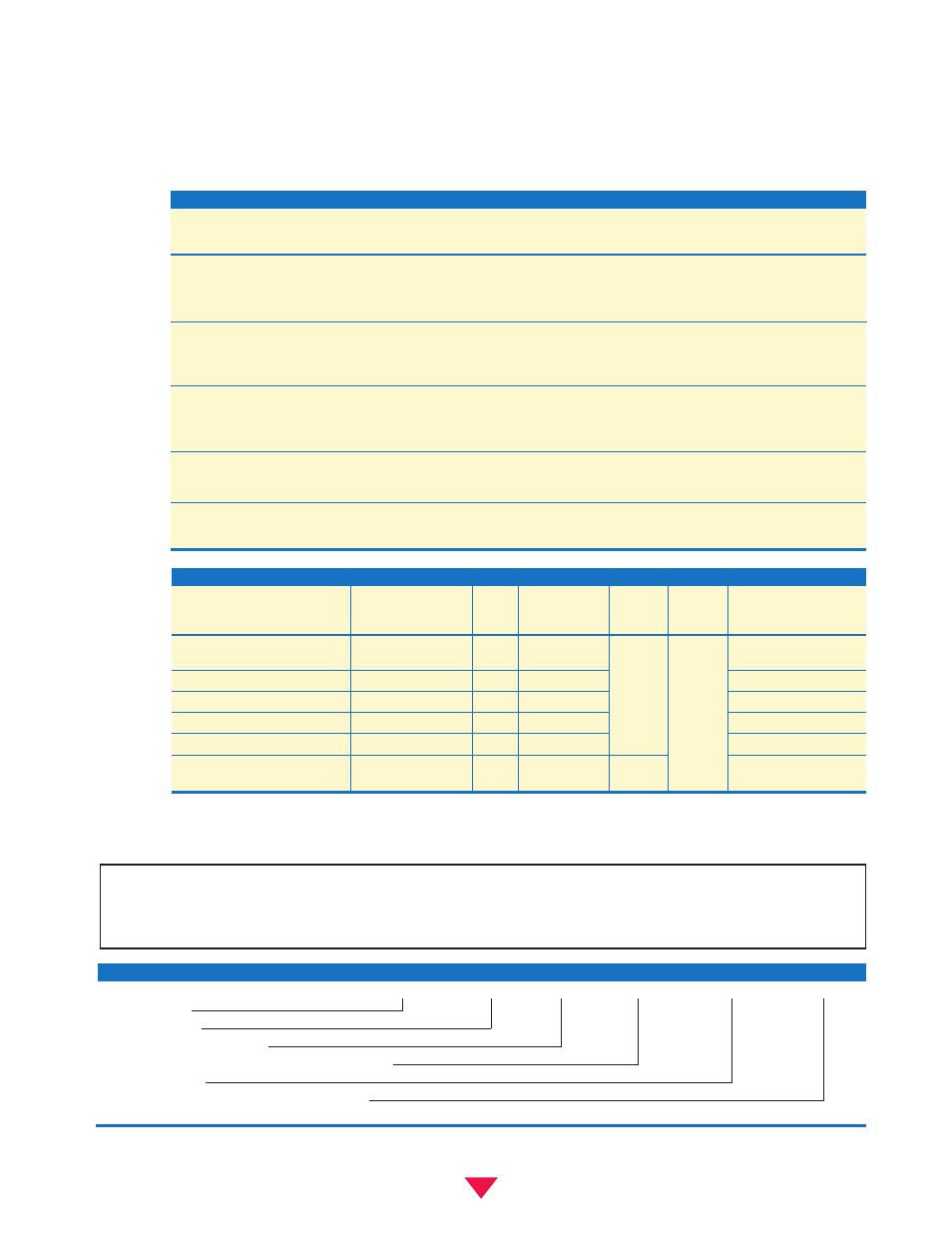

To order a Duragauge (sample coding shown)

Select:

45

1279

RS*

04L

XXX

0/2,000 psi

1. Dial size–4

1

⁄

2

˝

2. Case type–1279

3. Bourdon tube and socket code

4. Connection–

1

⁄

4

NPT (02),

1

⁄

2

NPT (04), Lower (L), Back (B)

5. Optional features

6. Pressure range (see range tables on pages 10 & 11)

Table A – Case selection & mounting

Ring: Style

Dial Size

Ordering

Case

Case: Material

Material

Mounting/Connection

(in)

Code

Type

Finish

Finish

4

1

⁄

2

(45)

1279

(1 )

Phenolic

Threaded

Stem–

Lower or back

(Black)

Reinforced

Surface– Lower or back

Polypropylene

Flush–

Back: Specify X56

(Black)

4

1

⁄

2

, 6, 8

1

⁄

2

(45)(60)(85)

1377

Aluminum

Hinged

Flush–

Back

Black epoxy coating

Steel

Stem–

Lower or back

Black wrinkle

enamel coat

4

1

⁄

2

, 6, 8

1

⁄

2

(45)(60)(85)

1379

(1 )

Aluminum

4

1

⁄

2

˝, 6˝ Threaded rein-

Stem–

Lower or back

Black epoxy coating

forced polypropylene

Surface– Lower or back

8

1

⁄

2

˝ Hinged steel, black

Flush–

Back, specify X56

wrinkle enamel coat

8

1

⁄

2

˝ standard

6

(45)

2462

Polypropylene

Bayonet lock

Stem–

Lower or back

(fiberglass reinforced)

Polypropylene

Surface– Lower or back, specify XBF

(Black)

(Black)

Flush–

Back, specify XBQ

6

(60)

1379

(1 )

Aluminum

6˝ Threaded rein-

Flush–

Lower or back

(high pressure)

Black epoxy coating

forced polypropylene

Surface– Lower or back

How to Order

Ashcroft

®

Duragauge

®

Pressure Gauge

NOTES:

(1) Liquid-fillable or hermetically sealed when kit 101A202-01 (lower) or kit 101A203-01 (back) is ordered.

(2) For selection of the correct Bourdon system material, see the media application table on page 9.

(3) Use on applications where NACE MR-01-75 is specified for selection of the correct Bourdon system material.

(

*

) “S” denotes solid front case design

Table B – System, connection & location

Bourdon Tube & Tip Material

(2)

Tube &

NPT

Conn.

(all joints TIG welded except code“A”)

Socket

Socket

Conn. &

Location &

Range Selection

Material

(2)

Code

Case Style Code

Code

Code

Limits (psi)

C510 Grade A Phosphor Bronze Tube

Brass

(A)

(S) Solid Front

Vac./1000

Brass Tip, Silver Brazed

(04)

1

⁄

2

4130 alloy steel

1018 steel

(B)

(S) Solid Front

(STD)

Lower (L)

Vac./5000

316 stainless steel

1018 steel

(R)

(S) Solid Front

(02)

1

⁄

4

Vac./20,000

316 stainless steel

316 stainless steel

(S)

(S) Solid Front

(OPT)

Back (B)

Vac./20,000

K 500 Monel

®(3)

Monel 400

(P)

(S) Solid Front

Vac./30,000

Inconel 718

®

316 stainless steel

(WW)

(SH) Solid Front

(09)

1

⁄

4

50,000/80,000/100,000

Herm. Sealed

High Pres.

13

GAUGE ACCURACY

Duragauge gauges are made in accordance with ANSI B40.1 (Gauges, pressure and vacuum, indicating dial type – elastic element), Accuracy

Grade 2A (±0.5% of span). Because of hysteresis, the downscale accuracy of a 20,000 psi gauge (S) or (R) code is 1.2%.

Maximum pressure at which a gauge is continually operated should not exceed 75% of full scale range.