Nexen 5H70P 917500 User Manual

Page 8

8

FORM NO. L-20008-V-0511

Although 5H Tooth Clutches are air actuated with a

maximum operating air pressure of 80 psi [5.52 bar], use

only enough air pressure to deliver ample torque for the

application. Operating air pressures in excess of 80 psi

[5.52 bar] will eventually cause accelerated bearing and

O-Ring seal damage.

Due to bearing seal drag, the cylinder/piston assembly will

rotate, resulting in hose breakage when clutch is engaged.

For models 5H30(P) through 5H60(P), resting the hose

against a support mounted parallel to the clutch centerline

stops this rotation.

On 5H70(P) and 5H80(P), where seal drag is more

apparent, a 3/8-16 tapped hole is provided 180° from the

air inlet. Install a bolt or stud in this hole and rest it against

a support to relieve stress on the hose. On the 5H100P, a

1/2-13 tapped hole is provided.

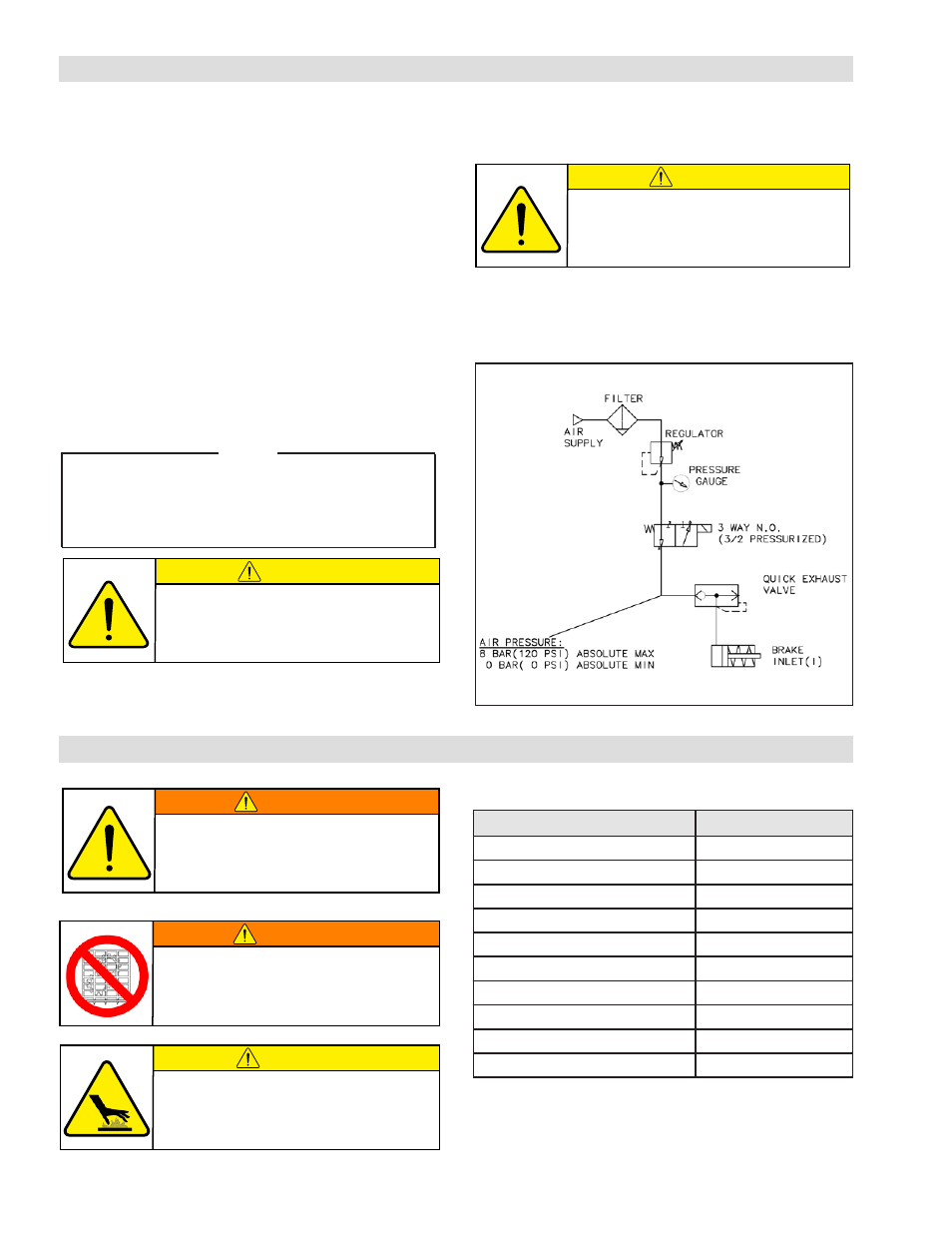

AIR CONNECTIONS

NOTE

For quick response, Nexen recommends a quick exhaust

valve and short air lines between the Control Valves and

the product. Align the air inlet ports to a down position

to allow condensation to drain out of the air chambers

of the product.

CAUTION

Low air pressure will cause slippage and

overheating. Excessive air pressure will

cause abrupt starts and stops, reducing

product life.

All Nexen pneumatically actuated devices require clean

and dry air, which meet or exceeds ISO 8573.1:2001

Class 4.4.3 quality.

The following is a common air supply scheme used with

this product. This is an example and not an all-inclusive

list. All air circuits to be used with this product must be

designed following EN983 guidelines.

OPERATION

WARNING

Never exceed maximum operating

speeds listed for your product.

(See Table 5).

CAUTION

The temperature limits for this

product line are 4.5-100 Degree

Celsius (40-220 Degree F).

TABLE 5

Size

Max RPM

5H20P

4000

5H30, 5H30P

3700

5H35, 5H35P

3200

5H40, 5H40P

3000

5H45, 5H45P

3000

5H50, 5H50P

3000

5H60, 5H60P

2400

5H70, 5H70P

2000

5H80P

2000

5H100P

1000

WARNING

Ensure proper guarding of the product is

used. Nexen recommends the machine builder

design guarding in compliance with OSHA 29

CFR 1910 “Occupational Safety and Health

Hazards”.

CAUTION

Rigid pipe or tubing when connected directly

to the clutch will prevent proper actuation of

the clutch. Use only flexible hose or tubing

when making air line connections to clutch.

- 5H60P 917400 5H50P 917300 5H45P 917200 5H40P 917100 5H35P 917000 5H30P 916900 5H100P 916710 5H60P 910403 5H80P 916100 5H70 916800 5H60 916700 5H50 916600 5H45 916500 5H40 916400 5H35 916300 5H30 916200 5H50S 910328 5H80P 911703 5H70P 910504 5H50P 910303 5H45P 910203 5H40P 910103 5H35P 910003 5H30P 909903 5H80P 911702 5H80P 911719 5H70P 910525 5H80P 911704 5H70P 910503 5H60P 910433 5H50P 910305