Nexen 5H70P 917500 User Manual

Page 7

7

FORM NO. L-20008-V-0511

INSTALLATION (continued)

5. Tighten the Set Screws (Item 16) to the recommended

torque (See Table 4).

NOTE: In severe use applications, the Tooth Clutch may

tend to move axially along the shaft. To prevent this

axial movement, confine the Tooth Clutch between

its shoulders or insert spring pins through the

clutch hub into the shaft.

Tooth Clutches may be mounted horizontally or

vertically. Nexen recommends the Drive Flange

face up to enhance spring return function when

mounting Tooth Clutches in the vertical position.

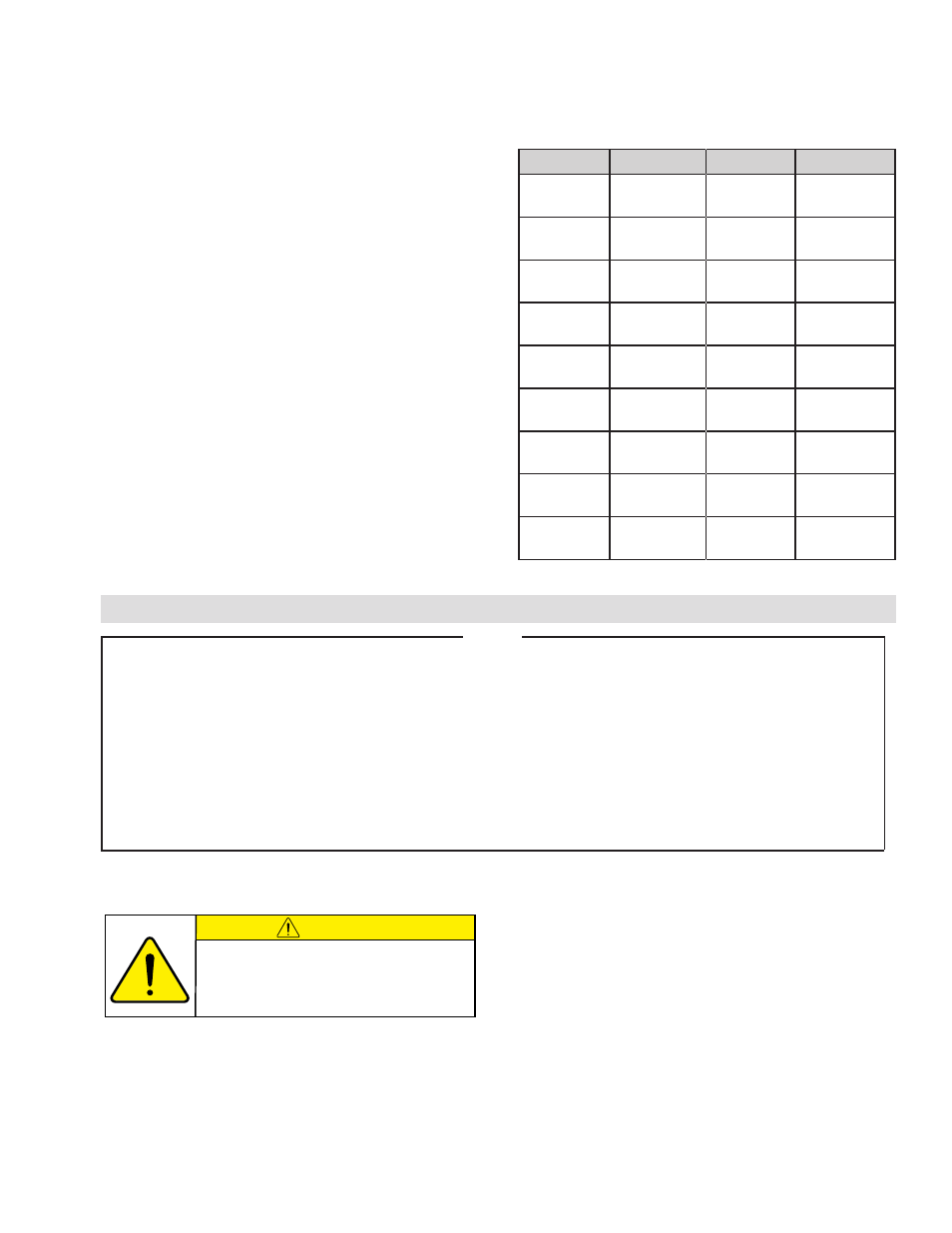

TABLE 4

RECOMMENDED TIGHTENING TORQUE (ITEM16)

MODEL

TORQUE

MODEL

TORQUE

5H30

13.8 In. Lbs.

[1.55 Nm]

5H30P

13.8 In. Lbs.

[1.55 Nm]

5H35

13.8 In. Lbs.

[1.55 Nm]

5H35P

13.8 In. Lbs.

[1.55 Nm]

5H40

13.8 In. Lbs.

[1.55 Nm]

5H40P

13.8 In. Lbs.

[1.55 Nm]

5H45

13.8 In. Lbs.

[1.55 Nm]

5H45P

13.8 In. Lbs.

[1.55 Nm]

5H50

6.6 Ft. Lbs.

[8.94 Nm]

5H50P

6.6 Ft. Lbs.

[8.94 Nm]

5H60

6.6 Ft. Lbs.

[8.94 Nm]

5H60P

6.6 Ft. Lbs.

[8.94 Nm]

5H70

6.6 Ft. Lbs.

[8.94 Nm]

5H70P

6.6 Ft. Lbs.

[8.94 Nm]

-

-

5H80P

100 Ft. Lbs.

[135.6 Nm]

-

-

5H100P

167 Ft. Lbs.

[226 Nm]

NOTE

Nexen pneumatically actuated devices require clean, pressure regulated air for maximum performance and

life. All seals in Nexen pneumatically operated devices are lubricated for life, and do not require additional

lubrication.

However, some customers prefer to use an air line lubricator, which injects oil into the pressurized air, forcing

an oil mist into the air chamber. This is acceptable, but care must be taken to ensure once an air mist lubrication

system is used, it is continually used over the life of the product as the oil mist may wash free the factory

installed lubrication.

Locate the lubricator above and within ten feet of the product, and use low viscosity oil such as SAE-10.

Synthetic lubricants are not recommended.

Nexen product's bearings are shielded and pre-lubricated, and require no further lubrication.

LUBRICATOR DRIP RATE SETTINGS

1. Close and disconnect the air line from the unit.

2. Turn the Lubricator Adjustment Knob counterclockwise

three complete turns.

3. Open the air line.

LUBRICATION

CAUTION

These settings are for Nexen supplied

lubricators. If you are not using a Nexen

lubricator, calibration must follow the

manufacturer's suggested procedure.

4. Close the air line to the unit when a drop of oil forms

in the Lubricator Sight Gage.

5. Connect the air line to the unit.

6. Turn the Lubricator Adjustment Knob clockwise until

closed.

7. Turn the Lubricator Adjustment Knob counterclockwise

one-third turn.

8. Open the air line to the unit.

- 5H60P 917400 5H50P 917300 5H45P 917200 5H40P 917100 5H35P 917000 5H30P 916900 5H100P 916710 5H60P 910403 5H80P 916100 5H70 916800 5H60 916700 5H50 916600 5H45 916500 5H40 916400 5H35 916300 5H30 916200 5H50S 910328 5H80P 911703 5H70P 910504 5H50P 910303 5H45P 910203 5H40P 910103 5H35P 910003 5H30P 909903 5H80P 911702 5H80P 911719 5H70P 910525 5H80P 911704 5H70P 910503 5H60P 910433 5H50P 910305