Installation (continued), Caution, Table 3 figure 1 – Nexen 5H70PSP 914000 User Manual

Page 6: Table 4

6

FORM NO. L-20060-U-1209

TaBle 3

FIGure 1

Clutch

Coupling, Sprocket,

Gear, or Pulley

Customer

supplied

Key

Optional

Hub Collar

Shaft

Set Screw

(Item 20)

r

o

F

l

e

d

o

M

r

a

ll

o

C

.

D

.

O

E

R

O

B

t

c

u

d

o

r

P

.

o

N

d

e

p

p

a

T

s

e

l

o

H

d

e

ri

u

q

e

r

.

C

.

B

N

I

M

M

P

S

P

0

3

H

5

8

/

5

-

1

5

7

8

.

3

2

.

2

2

0

0

3

4

2

9

2

3

-

6

)

3

(

6

1

/

3

-

1

P

S

P

5

3

H

5

6

1

/

5

1

-

1

5

2

1

.

1

8

5

.

8

2

0

0

4

4

2

9

2

3

-

6

)

3

(

6

1

/

7

-

1

P

S

P

0

4

H

5

6

1

/

5

1

-

1

0

5

2

.

1

5

7

.

1

3

0

0

5

4

2

9

0

4

-

4

)

4

(

2

/

1

-

1

P

S

P

5

4

H

5

8

/

5

-

2

0

0

5

.

1

0

1

.

8

3

0

0

6

4

2

9

2

3

-

8

)

3

(

-

3

/

9

2

-

1

2

P

S

P

0

5

H

5

4

/

3

-

2

0

5

7

.

1

5

4

.

4

4

0

0

7

4

2

9

2

3

-

8

)

3

(

2

3

/

5

-

2

P

S

P

0

6

H

5

8

/

1

-

3

7

3

9

.

1

0

2

.

9

4

0

0

8

4

2

9

2

3

-

0

1

)

3

(

6

1

/

7

-

2

P

S

P

0

7

H

5

2

/

1

-

3

7

8

1

.

2

5

5

.

5

5

0

0

9

4

2

9

2

3

-

0

1

)

3

(

-

1

/

1

1

-

2

6

P

S

P

0

8

H

5

4

7

3

9

.

2

0

6

.

4

7

0

0

0

5

2

9

4

2

-

0

1

)

3

(

-

6

/

9

1

-

3

4

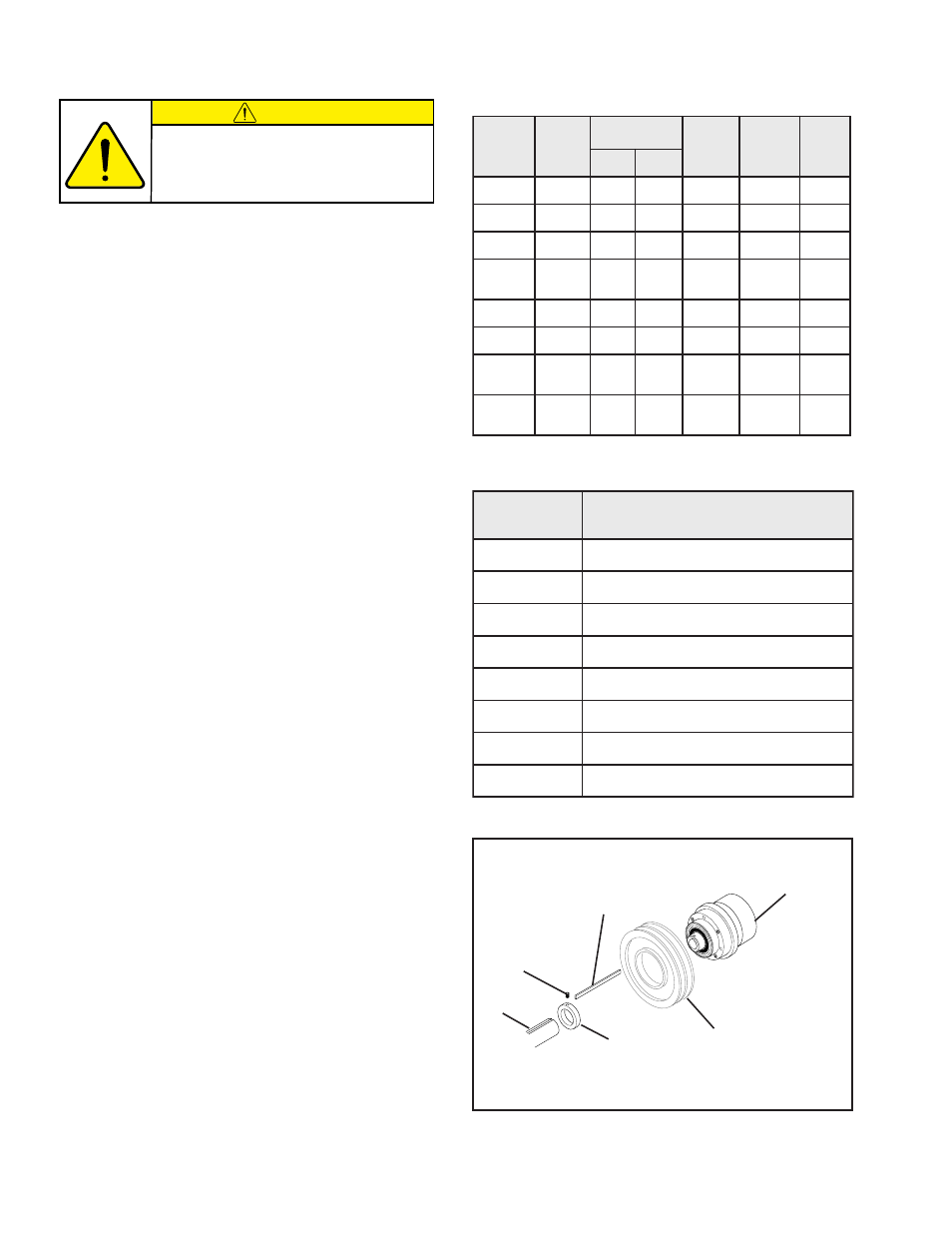

Mounting positions of the Tooth Clutch may be vertical

or horizontal. In the vertical position Nexen recommends

locating the drive flange in an upward position to enhance

the spring return function.

To prevent the clutch bearings from unnecessary rotation,

align the input drive to the clutch through the drive flange

whenever possible.

In severe use applications, the clutch may tend to move

axially along the shaft. To prevent this axial movement,

confine the clutch between shoulders or insert spring pins

through the clutch hub into the shaft.

An optional Hub Collar is available if set screws are required

on the opposite end of the clutch. Order the Collar by

Product Number (See Table 3).

The optional Hub Collar requires drilling and tapping of

holes in the end of the clutch hub. Use the Collar as a hole

location template.

nOTe: all “5HP-SP” Clutches mount on a full shaft

using a customer supplied full length key.

A. Install Nexen’s Flexible Coupling, pulley, sprocket, or

gear (See Fig. 1 & Table 2).

B. Insert customer supplied key (See Fig. 1).

C. Slide optional Locking Hub Collar if used (See Figure

1)

D. Slide Clutch onto shaft and customer supplied key

(See Figure 1).

E. Using Set Screws (Item 20) Secure Clutch to shaft

(See Figure 1).

F. Tighten Set Screws (Item 20) to recommended torque

(See Table 4).

CAUTION

Do not connect in-line without using the Nexen

Flexible Coupling. The internal construction

of the "5HP-SP" Clutch will not allow any

misalignment tolerance. (Refer to Sales

Literature L-20208).

InSTallaTIOn (continued)

TaBle 4

L

E

D

O

M

W

E

R

C

S

T

E

S

D

E

D

N

E

M

M

O

C

E

R

E

U

Q

R

O

T

G

N

I

N

E

T

H

G

I

T

P

S

P

0

3

H

5

.

b

L

.

n

I

8

.

3

1

P

S

P

5

3

H

5

.

b

L

.

n

I

8

.

3

1

P

S

P

0

4

H

5

.

b

L

.

n

I

8

.

3

1

P

S

P

5

4

H

5

.

b

L

.

n

I

8

.

3

1

P

S

P

0

5

H

5

.

b

L

.t

F

6

.

6

P

S

P

0

6

H

5

.

b

L

.t

F

6

.

6

P

S

P

0

7

H

5

.

b

L

.t

F

6

.

9

5

P

S

P

0

8

P

H

5

.

b

L

.t

F

6

.

9

5