Introduction, Installation – Nexen 5H70PSP 914000 User Manual

Page 5

5

FORM NO. L-20060-U-1209

InTrODuCTIOn

Nexen “5HP-SP” Single Position Tooth Clutches are

designed for applications where exact timing of two

components is required. When engaged, static air pressure

squeezes the teeth together (in the same position each time)

that lock in for absolutely no slippage or loss of torque.

Tooth clutches are normally engaged when stationary. In

certain circumstances, such as low RPM, tooth clutches

can be engaged at differential speed up to 150 RPM. The

allowable engagement speed is a function of the rotational

inertia of the mass being accelerated and the air pressure

applied.

If the tooth clutch is to be engaged in other than static

conditions, solve the following “Differential Speed” formula

to make sure the application’s differential speed is within

the limits of the selected tooth clutch.

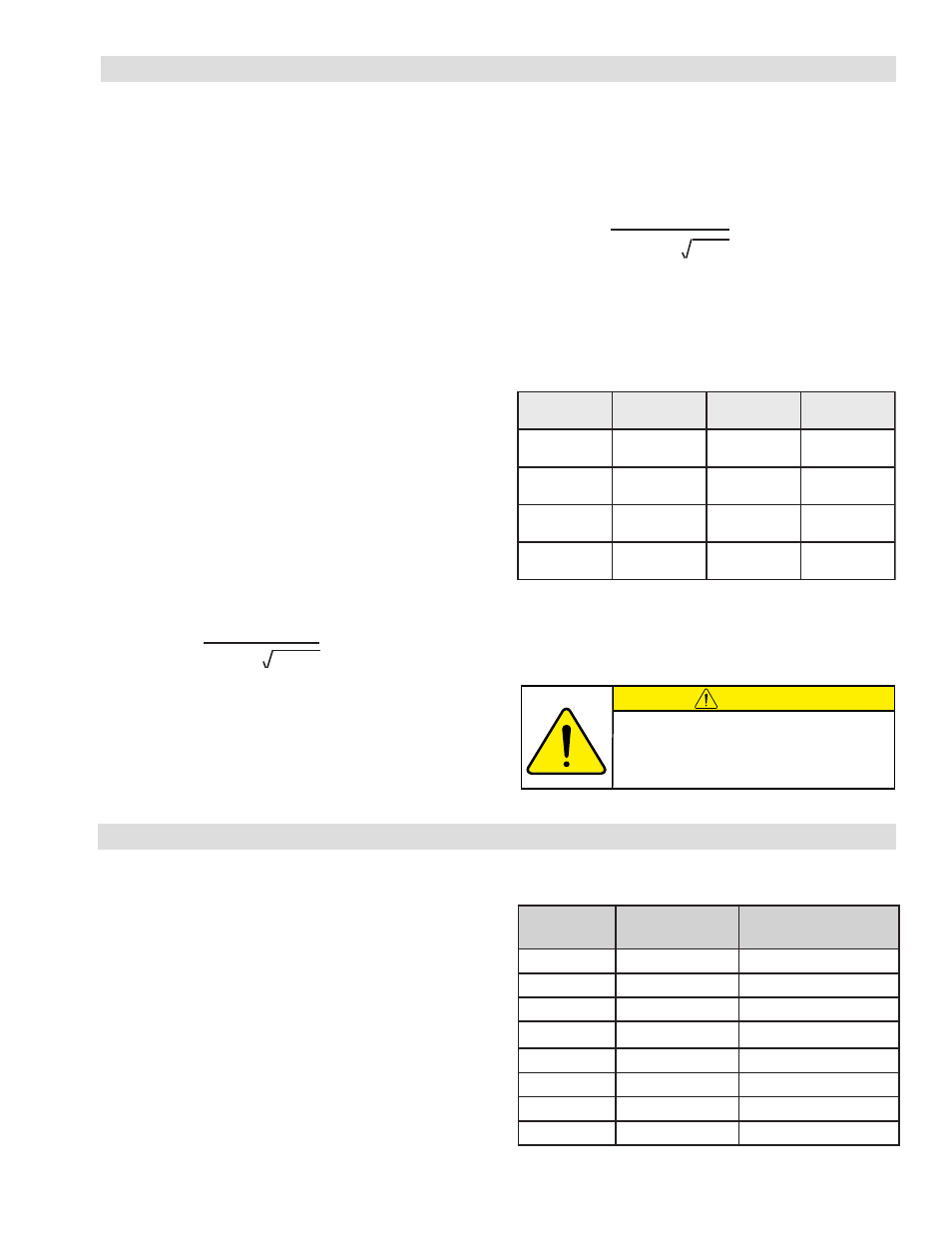

DIFFERENTIAL SPEED FORMULA

Use the Differential Speed Formula to find the allowable

engagement speed (n) at a specific air pressure setting (P)

with a given inertial load (WK

2

). This formula expresses the

relationship of the variables involved that effect the impact

of the face teeth during engagement. Tooth damage can

occur when tooth velocity and air pressure settings are too

high (i.e., a smaller clutch has a lower tooth velocity at any

given RPM, and a small clutch has less driver inertia).

V(10

4

)

N =

(P-22) WK

2

Where: n = Differential RPM Limit Clutch

V = Constant for Clutch (See Table 1)

P = Operational Pressure. PSI

WK

2

= Referred Inertia lb. • ft

2

eXaMPle: The required differential engagement speed

using a Model “5H45P-SP” clutch at 60 PSI is 150 RPM.

(Clutch rotating at 1250, machine component rotating at

1100). The referred inertial is 3 lb. • ft

2

. The differential

RPM limit for the clutch is:

1.4 (10

4

)

N =

= 213 RPM

(60-22) 3

150 RPM is within the limit of the “5H45P-SP” operating

at 60 PSI with a load of 3 lb. • ft.

2

.

TaBle 1

COnSTanTS FOr CluTCHeS

H

C

T

U

L

C

T

N

A

T

S

N

O

C

H

C

T

U

L

C

T

N

A

T

S

N

O

C

P

S

-

P

0

3

H

5

0

1

.

2

P

S

-

P

0

5

H

5

6

2

.

1

P

S

-

P

5

3

H

5

0

8

.

1

P

S

-

P

0

6

H

5

5

0

.

1

P

S

-

P

0

4

H

5

7

5

.

1

P

S

-

P

0

7

H

5

0

9

.

P

S

-

P

5

4

H

5

0

4

.

1

P

S

-

P

0

8

H

5

8

7

.

CAUTION

If differential speed exceeds the clutch

limitations, ratcheting of the teeth can

occur that will shorten clutch life.

NOTE: Formula does not estimate:

1 RPM that prevents ratcheting.

2 Acceleration time.

3 Tooth stress after engagement.

InSTallaTIOn

The “5HP-SP” Clutch has a drive flange with two bearings,

a pilot diameter, and tapped holes for mounting a pulley,

sprocket, or Nexen’s Flexible Coupling (See Table 2 for

recommended tightening torques).

nOTe: nexen recommends using a red anaerobic

thread locking compound on Pilot Mounting

Bolts.

Nexen’s Flexible Coupling combined with “5HP-SP” Tooth

Clutches provides high misalignment capabilities for in-line

shaft connections.

TaBle 2

Model

Screw Size

metric [inch]

Tightening

Torque

5H30P-SP

M6 [1/4-20]

17.6 Nm [13 ft.lb.]

5H35P-SP

M6 [1/4-20]

17.6 Nm [13 ft.lb.]

5H40P-SP

M6 [1/4-20]

17.6 Nm [13 ft.lb.]

5H45P-SP

M6 [1/4-20]

17.6 Nm [13 ft.lb.]

5H50P-SP

M8 [5/16-18]

36.6 Nm [27 ft.lb.]

5H60P-SP

M8 [5/16-18]

36.6 Nm [27 ft.lb.]

5H70P-SP

M10 [1/2-13]

161.3 Nm [119 ft.lb.]

5H80P-SP

M12 [1/2-13]

161.3 Nm [119 ft.lb.]