Nexen XHW 848200 User Manual

Page 6

6

FORM NO. L-20004-K-1209

NOTE

Nexen pneumatically actuated devices require clean, pressure regulated air for maximum performance and

life. All seals in Nexen Pneumatically operated devices are lubricated for life and do not require additional

lubrication.

However, some customers prefer to use an air line lubricator, which injects oil into the pressurized air, forcing an

oil mist into the air chamber. This is acceptable, but care must be taken to ensure once an air mist lubrication

system is used, it is continually used over the life of the product as the oil mist may wash free the factory

installed lubrication.

Locate the lubricator above and within ten feet of the product, and use low viscosity oil such as SAE-10.

Synthetic lubricants are not recommended.

Nexen product's bearings are shielded and pre-lubricated, and require no further lubrication.

LUBRICATOR DRIP RATE SETTINGS

1. Close and disconnect the air line from the unit.

2. Turn the Lubricator Adjustment Knob counterclockwise

three complete turns.

3. Open the air line.

LUBRICATION

CAUTION

These settings are for Nexen supplied

lubricators. If you are not using a Nexen

lubricator, calibration must follow the

manufacturer's suggested procedure.

4. Close the air line to the unit when a drop of oil forms

in the Lubricator Sight Gage.

5. Connect the air line to the unit.

6. Turn the Lubricator Adjustment Knob clockwise until

closed.

7. Turn the Lubricator Adjustment Knob counterclockwise

one-third turn.

8. Open the air line to the unit.

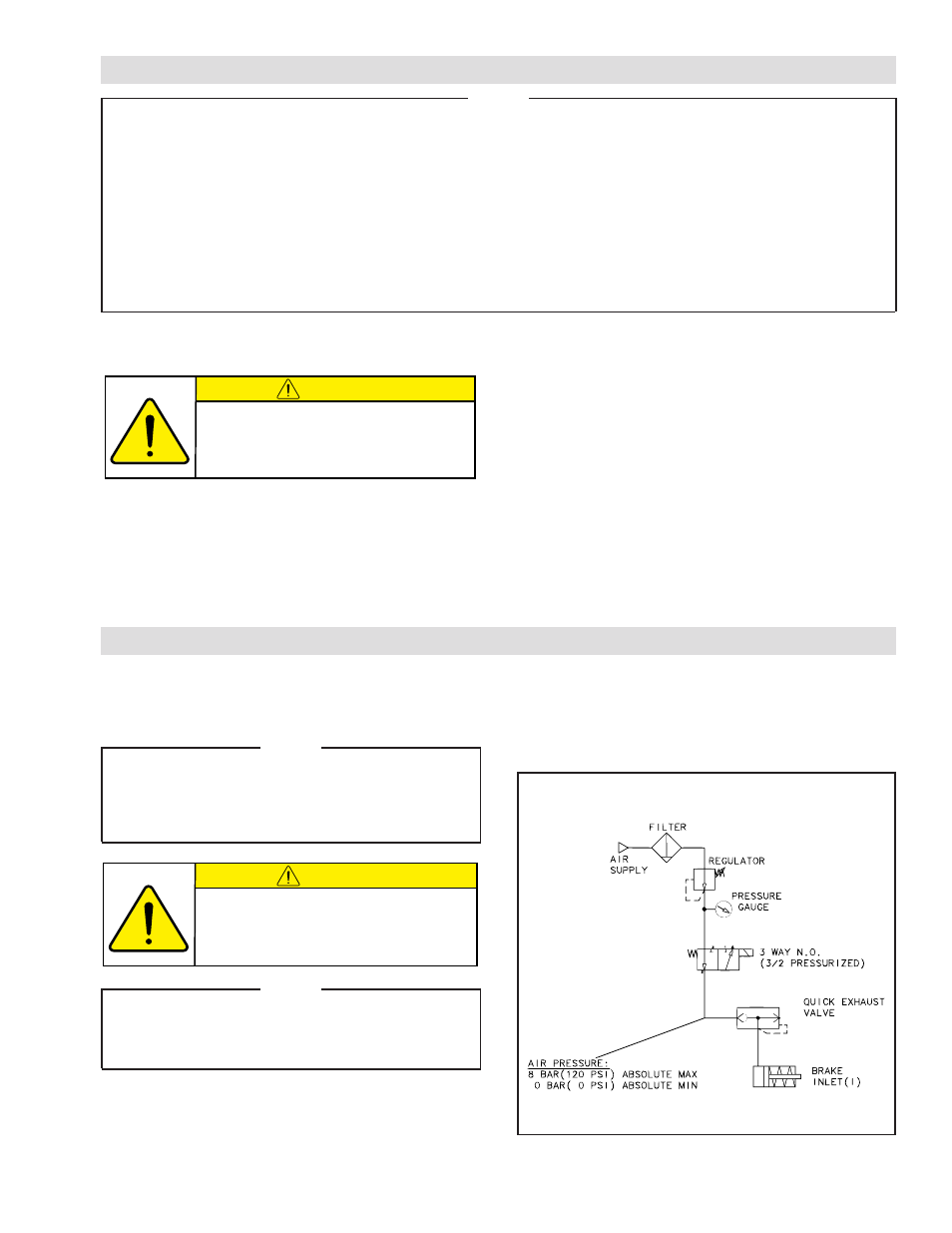

AIR CONNECTIONS

NOTE

For quick response, Nexen recommends a quick exhaust

valve and short air lines between the Control Valves and

the product. Align the air inlet ports to a down position

to allow condensation to drain out of the air chambers

of the product.

CAUTION

Low air pressure will cause slippage and

overheating. Excessive air pressure will

cause abrupt starts and stops, reducing

product life.

All Nexen pneumatically actuated devices require clean

and dry air, which meet or exceeds ISO 8573.1:2001

Class 4.4.3 quality.

The following are common air supply schemes used with

this product. These are examples and not an all-inclusive

list. All air circuits to be used with this product must be

designed following EN983 guidelines.

NOTE

The use of rigid pipe or tubing, when connected directly to

the clutch will prevent proper actuation of the unit due to

the necessary movement of the air chamber and hose upon

engagement. Use only flexible hose or tubing.

Due to bearing seal drag, the outer portion of the clutch will rotate

when the clutch is engaged, a 7/16 inch diameter rod inserted

into the 1/2-inch diameter hole located in the Piston (Item #6) and

fastened to a fixed pipe will prevent damage to the hose.