Nexen I300 965502 User Manual

Page 7

7

FORM NO. L-21226-B-1008

Bearing Replacement

1. To replace bearing (Item 2) remove retaining ring

(Item 10) and press the hub (Item 10) out of the

bearing. Then press the bearing (Item 2) from the

spring plate (Item 18). Be sure to clean the excess

Loctite‚ from both bores before reassembling, use

fresh safety solvent to clean.

2. Apply a continuous bead of Loctite‚ 680 (Green)

around the outer circumference of the new bearing

(Item 2), press the new bearing into the spring

housing (Item 18), press on the outer race of the

bearing for this process.

3. While supporting the inner race of the bearing press

the hub (Item 1) into the bearing and replace the

retaining ring( Item 10)

O-Ring Replacement

1. Remove the piston (Item 5), then remove O-rings

(Item 3,4) from piston grooves.

Note: A small amount of compressed air may be

required to remove piston.

2. Visually inspect the piston and housing O-ring

contact area for debris, clean as required.

3. Coat the O-ring contact surfaces of the Housing

(Item 6) and the O-rings (Item 3,4) with a thin film

of O-ring lubrication. Install O-rings into O-ring

grooves in piston.

4. Install piston into housing.

Reassembly

1. Before reassembly, clean housing (Item 6) and hub

(Item 5) with a safety solvent. Make sure to clean

any Loctite residue from the friction interface areas.

2. Considering the following guidelines, reassembly

brake by following Disassembly steps 1 thru 7 in

reverse order.

a. Apply a continuous bead of Loctite‚ 680

(Green) around the outer circumference of

spring housing (Item 18).

b. Be sure to align groove in spring housing (Item

18) to set screw hole in housing (Item 6).

c. Tighten setscrew (Item 14) to 80 Nm.

Note: Brake will not have full torque immediately

after replacing friction facings, it is required the

facing goes through a “Break in” procedure. Run

the brake under full load at 1 RPM for 6 minutes to

“Break in” this brake.

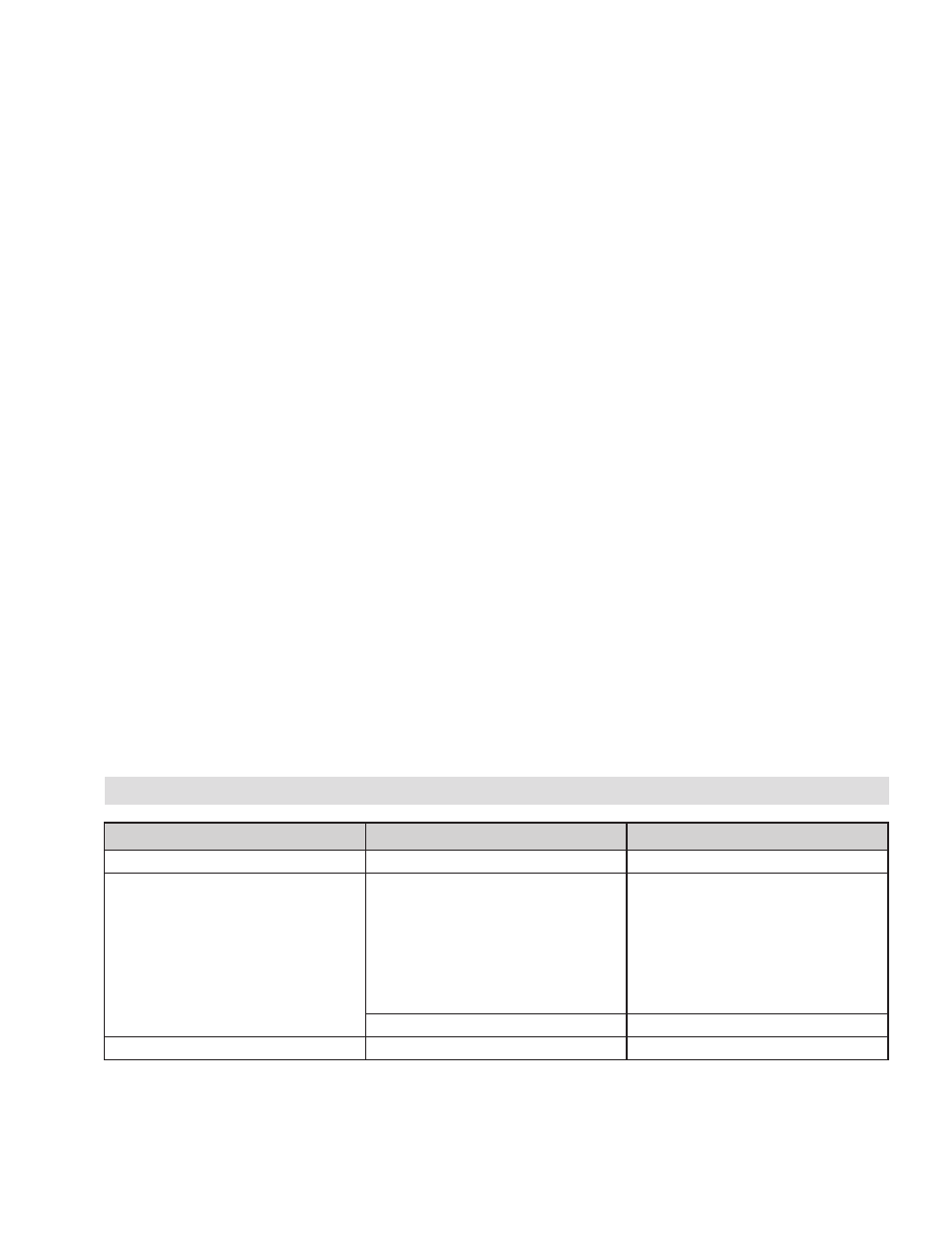

TROUBLESHOOTING

pROBLEm

pROBABLE CAUSE

SOLUTION

Failure to engage (brake)

Weak or broken springs

Replace broken springs

Failure to disengage

Control valve malfunction - air not getting

to the brake.

Check for low air pressure or replace the

control valve.

NOTE: The unit has been designed to

release before (at or below) 4.1 bar [60

psi]. Required disengagement pressure

higher than 4.1 bar [60 psi] may indicate

improper assembly.

Air is leaking around the O-ring seals

Replace the O-rings

Loss of torque

Friction Facing is worn or dirty

Replace the Friction Facing