Installation – Nexen I300 965502 User Manual

Page 4

FORM NO. L-21226-B-1008

4

INSTALLATION

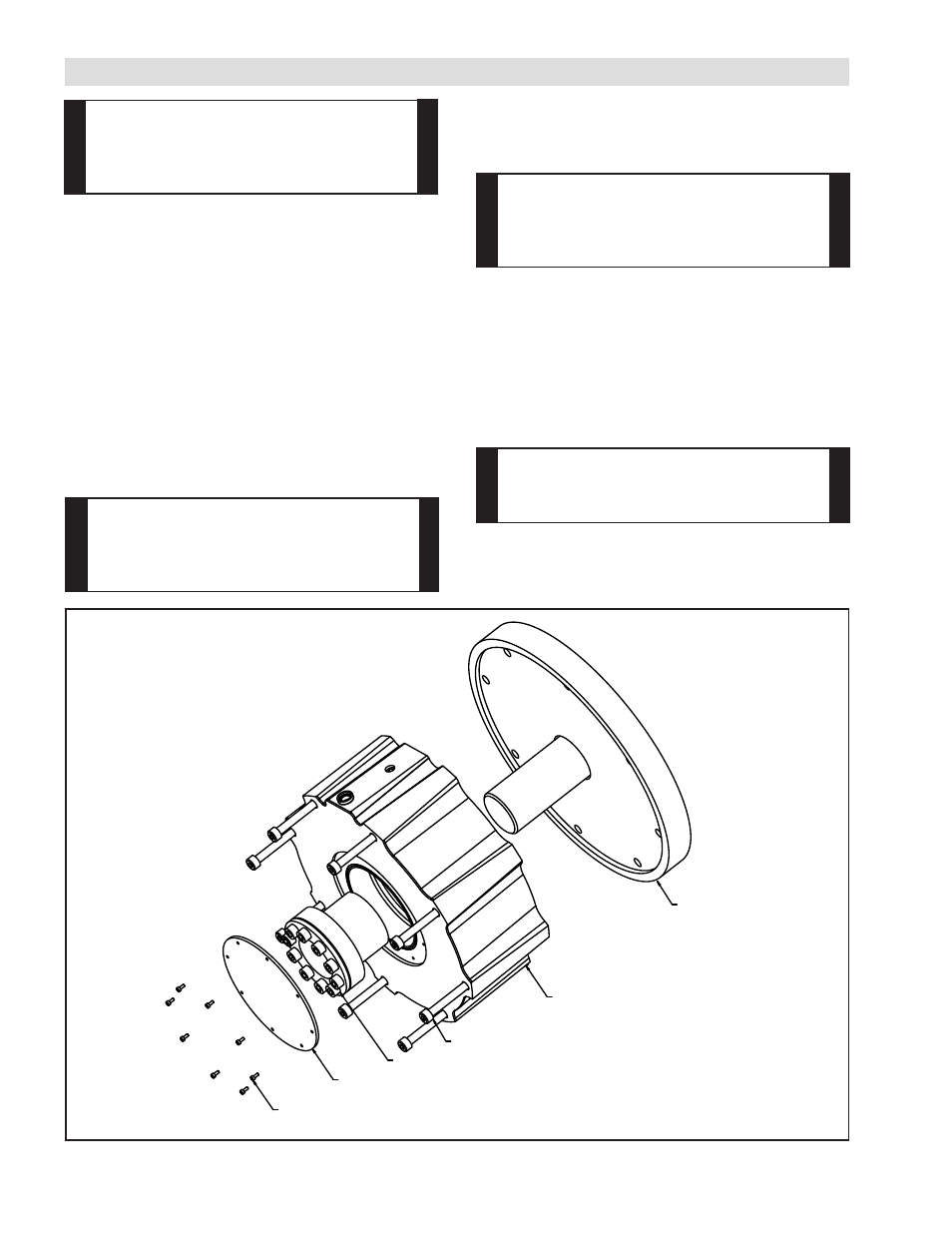

Refer to figure 1 for the following steps.

1. Remove cover (Item 7) by removing the 8 cap

screws (Item 11) before installation

2. Mount brake to machine bulkhead using 8 customer

supplied M8 cap screws***, the outside diameter of

the brake should be used as a pilot to ensure proper

alignment with the machine shaft.

*** Each end of the brake’s mounting holes is

threaded with M10 X 1.25 threads to depth

20.0 (.79 in); the brake may be mounted using

these threaded holes if it is a better fit for a given

application.

Danger

Ensure all loads are supported before installing

brake. Failure to support the load could result in

serious bodily injury.

Important

The locking collar used for mounting must be a

non-translating type. If the wrong type of collar

is used, damage to the brake will occur.

Important

The mounting edge of this brake is not sealed,

if using the brake in a wet environment ensure a

flange sealant is used to keep water from

entering the brake.

3. Install the customer supplied locking collar into

brake, do not lubricate either the clamping collar or

shaft, do not tighten collar at this point.

MACHINE BULKHEAD

MOUNTING SCREWS

*CUSTOMER SUPPLIED COLLAR*

ITEM 7

ITEM 11

I300

Figure 1

4. With the brake mounted rigidly to the customer’s

bulkhead and the brake in the ENGAGED position,

tighten the cap screws on the collar to the

manufactures recommended torque.

5. Apply sealant (silicone or RTV) to o-ring before

installing the cap. Install the cap (item 7) using the

8 cap screws (Item 11).

Danger

Brake housing has sharp corners,

guard brake as required.