Warning – Metalfab Motorized Trolley MR Series User Manual

Page 35

35

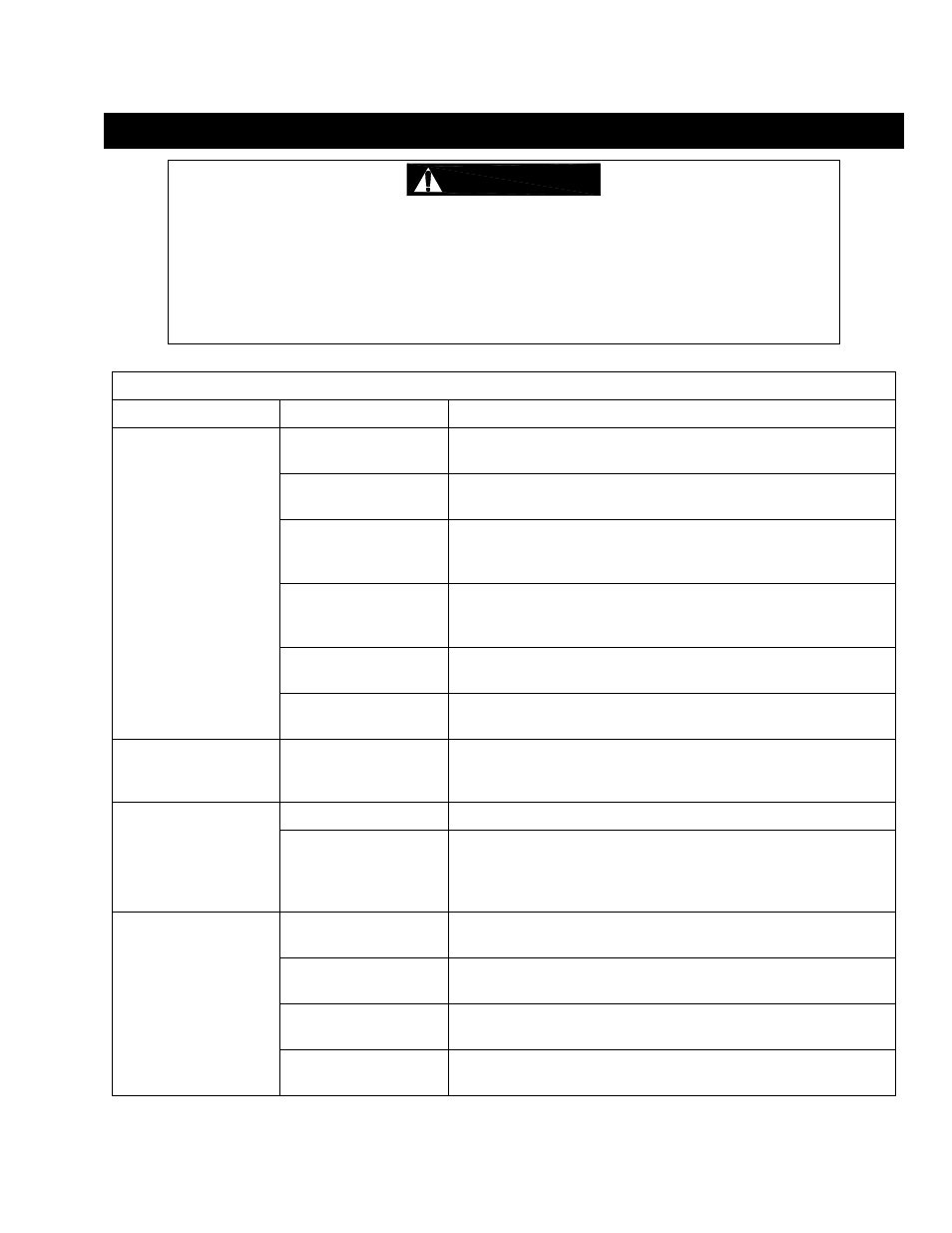

7.0 Troubleshooting

WARNING

HAZARDOUS VOLTAGES ARE PRESENT IN THE TROLLEY AND IN CONNECTIONS

BETWEEN COMPONENTS.

Before performing ANY maintenance on the equipment, de-energize the supply of electricity to the

equipment, and lock and tag the supply device in the de-energized position. Refer to ANSI Z244.1,

“Personnel Protection – Lockout/Tagout of Energy Sources.”

Only Trained and competent personnel should inspect and repair this equipment.

Table 7-1

Troubleshooting Guide

Symptom

Cause

Remedy

Loss of power

Check circuit breakers, switches, fuses and connections on power

lines/cable.

Wrong voltage or

frequency

Check voltage and frequency of power supply against the rating

on the nameplate of the motor.

Motor overheated and

thermal overload

protector has tripped

See Trouble Shooting Problem "Motor or brake overheating".

Improper, loose, or

broken wire in trolley

electrical system

Shut off power supply, check wiring connections in the trolley

switch box, on hoist control panel and inside push-button pendant.

Faulty magnetic

contactor

Check coil for open or short circuit. Check all connections in the

control circuit. Check for open contactors. Replace as needed.

Trolley will not operate

Motor burned out

Replace motor frame/stator, shaft/rotor, and any other damaged

parts.

Trolley drifts

excessively when

stopping

Motor brake not

holding

Clean and inspect brake lining. Replace if necessary

Excessive duty cycle

Reduce frequency of trolley movement.

Motor or brake

overheating

Extreme external

heating

Above an ambient temperature of 140°F, the frequency of trolley

operation must be reduced to avoid overheating of the motor.

Special provisions should be made to ventilate the trolley or

otherwise shield it from the heat.

Collectors making poor

contact

Check movement of spring loaded arm, weak spring, connections,

and shoe. Replace as needed.

Contactor contacts

arcing

Check for burned contacts. Replace as needed.

Loose connection in

circuit

Check all wires and terminals for bad connections. Replace as

needed.

Trolley operates

intermittently

Broken conductor in

Pendant Cord

Check for intermittent continuity in each conductor the Pendant

Cord. Replace entire Pendant Cord if continuity is not constant.