Caution, Danger – Metalfab Motorized Trolley MR Series User Manual

Page 20

20

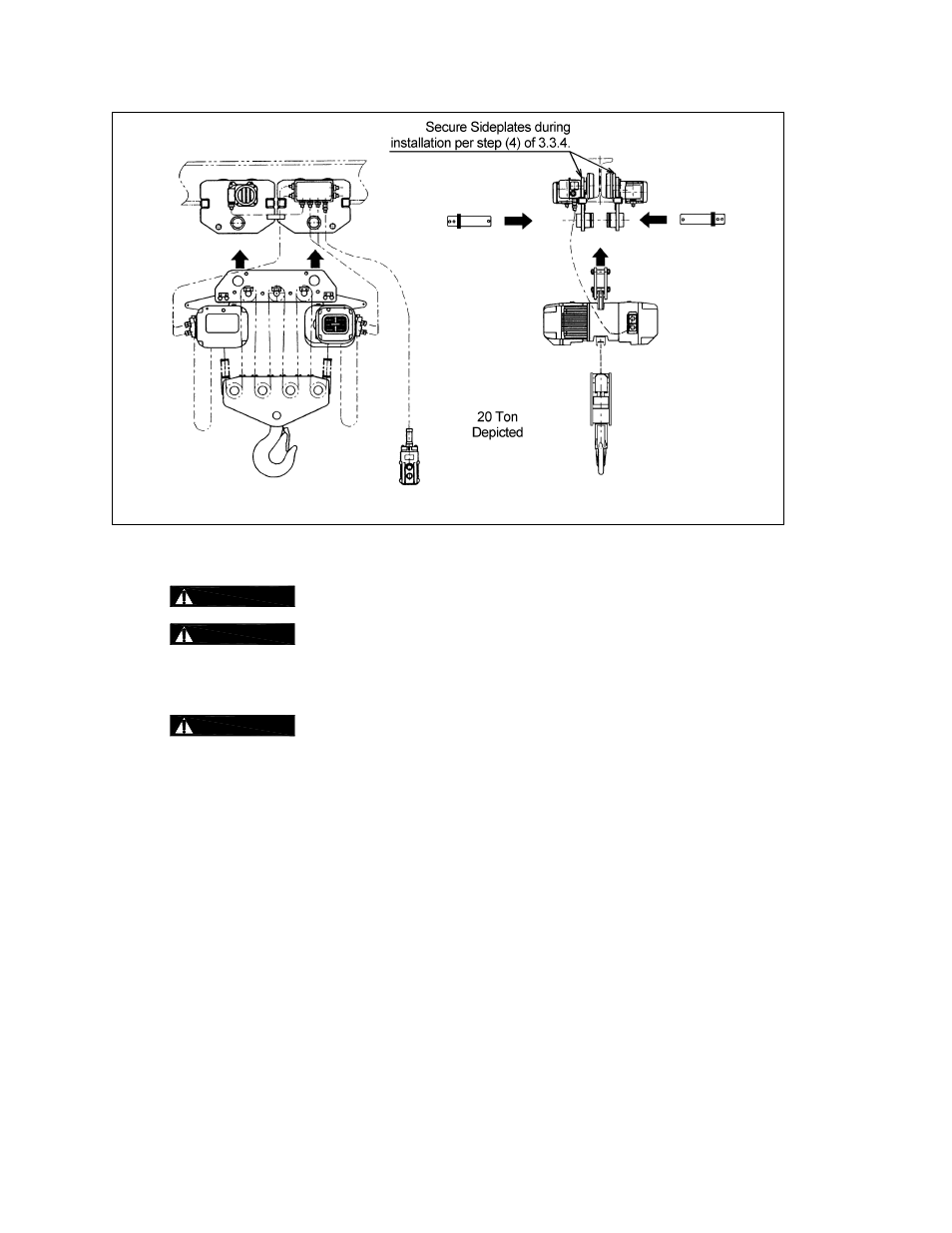

Figure 3-11

Optional trolley installation method – 8 Ton and Larger

3.4 Electrical

Connections

3.4.1

CAUTION

Ensure that the voltage of the electric power supply is proper for the hoist or trolley.

3.4.2

CAUTION

Do NOT apply electronic soft-start control or voltage varying controls to the MR

trolley. Use of such devices may cause the motor brake and other electrical components to

malfunction. Variable frequency drives MAY be used with MR trolleys, contact Harrington for more

information.

3.4.3

DANGER

Before proceeding, ensure that the electrical supply for the hoist or trolley has

been de-energized (disconnected). Lock out and tag out in accordance with ANSI Z244.1 “Personnel

Protection -Lockout/Tagout of Energy Sources”.

3.4.4

This instruction applies to installations where an ER or NER model electric hoist is installed on an MR

trolley. In this case the hoist and trolley are controlled by a pendant with four push buttons – two for the

hoist motion and two for the trolley motion. Special wiring considerations must be taken if the trolley is

used with a hoist other than an ER or NER model.

Pendant Cord - The Pendant Cord connects to the trolley via an 8-pin (8P) Plug and Socket. Make

this connection as follows:

1)

Refer to

Figure 3-12 or 3-13

depending on the product code of the trolley/hoist.

2)

Insert the 8P Plug into the 8P Socket on the Switch Box and hand tighten the Screw Coupling.

3)

For trolley/hoist code ERM001H to ERM100L – Install the Cord Strain Relief Cable to the Cord

Support on the Bar Holder.

4)

For trolley/hoist code ERM100S – install the Cord Strain Relief Cable onto Cord Strain Relief

Stopper located at the 8P socket.

5)

For trolley/hoist code ERM150S and ERM200S – Install the Cord Strain Relief Cable onto

Connection Plate S.